Need to get the paint off of the cases.

- Thread starter fiatfan

- Start date

- Status

- Not open for further replies.

lcrken

VIP MEMBER

- Joined

- Mar 15, 2009

- Messages

- 5,047

Crushed walnut shell media blasting is all I ever use on aluminum castings.

I recently cleaned all the paint off my '73 750 cases with plastic abrasive blasting. Came off really easily. Like Dave, I've used walnut shell media in the past, and it works too. I'm really surprised that the vapor blasting doesn't remove the paint. Whatever the factory used, it's a pretty thin coat, with no primer under it. Certainly not like a modern urethane or epoxy paint. Is it possible that a previous owner repainted the cases with something more durable?

Ken

fiatfan

VIP MEMBER

- Joined

- Aug 9, 2015

- Messages

- 524

I´ve done quite a bit of blasting, on aluminium I´ve only used glass beads which works fine, but the surface doesn´t get the right look. Never tried walnut shell or plastic abrasive, what is that by the way? The paint is probably the original, it´s really tough though it´s a pretty thin layer as you say. Remember that this was made before the expression "environmentally friendly" was invented, so it´s the real deal. I only wan´t to get it off because it´s been affected by petrol dripping from the carbs and the paint has gone yellow.I recently cleaned all the paint off my '73 750 cases with plastic abrasive blasting. Came off really easily. Like Dave, I've used walnut shell media in the past, and it works too. I'm really surprised that the vapor blasting doesn't remove the paint. Whatever the factory used, it's a pretty thin coat, with no primer under it. Certainly not like a modern urethane or epoxy paint. Is it possible that a previous owner repainted the cases with something more durable?

Ken

- Joined

- May 7, 2005

- Messages

- 7,327

The original paint was anything but tough, it wiped off with thinners on mine. Someone has added another paint if its as tough as you say.The paint is probably the original, it´s really tough

- Joined

- May 5, 2017

- Messages

- 657

Glass medis is OK for external surfaces. Never use sand or glass media on internal surfaces of the engine, primary or gearbox. Only use crushed walnut shells or plastic media for media blasting. Sand or glass media will enbed into the aluminum. When installed and raised to normal [hot] temps, the pores of the aluminum will open. The abrasive media trapped in the aluminum will then be released. This will then deposit the abrasive media into the oil. It will also end up inside the engine cylinders.I´ve done quite a bit of blasting, on aluminium I´ve only used glass beads which works fine, but the surface doesn´t get the right look. Never tried walnut shell or plastic abrasive, what is that by the way? snipped

lcrken

VIP MEMBER

- Joined

- Mar 15, 2009

- Messages

- 5,047

I also use glass beads regularly on aluminum bits, but didn't want to start the anti-glass bead wars all over again. I usually use glass beads to clean heads because the plastic beads and walnut shells don't seem aggressive enough to get the carbon deposits off. But they do work well for things like crankcases. I've used glass beads to clean engine parts for decades, and never had any negative effects from grit left in the castings. But I'm also very careful to clean them all very thoroughly in the solvent tank, followed by hot, soapy water, and blow out all the threads, passages, etc. with compressed air. I understand the logic of the arguments against that, but it's always worked for me. The best finish I've had on crankcases was from Excello plating, a local shop that got closed down decades ago by environmental regulations. They did a lot of aerospace and racing industry work, and I used them for plating, shot peening, crack inspection, and media blasting services. They were certified by all sorts of military and racing agencies. They cleaned my crankcases with glass beads followed by a low pressure blasting with steel shot. The shot closed up the surface pores and gave really nice semi-lustre finish. Now I just clean them myself and spray with a modern ceramic engine paint.I´ve done quite a bit of blasting, on aluminium I´ve only used glass beads which works fine, but the surface doesn´t get the right look. Never tried walnut shell or plastic abrasive, what is that by the way? The paint is probably the original, it´s really tough though it´s a pretty thin layer as you say. Remember that this was made before the expression "environmentally friendly" was invented, so it´s the real deal. I only wan´t to get it off because it´s been affected by petrol dripping from the carbs and the paint has gone yellow.

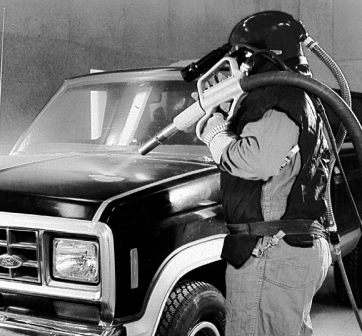

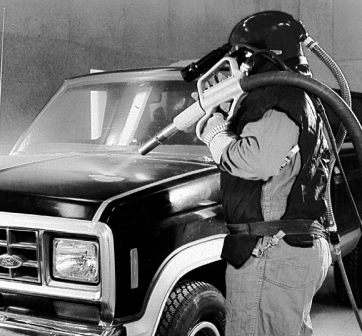

There's good information on plastic media here:

Plastic Blast Media | Paint Stripping | Blast Cleaning

Manufacturer of Plastic Media Abrasives for economical paint removal and blast cleaning. Excellent results on cars, trucks, airplanes, steel and aluminum.

This is similar to the media I've been using:

Ken

lcrken

VIP MEMBER

- Joined

- Mar 15, 2009

- Messages

- 5,047

Where would soda blasting fit into the spectrum for blasting safety vs effectiveness?

Good question. I have a cheap soda blaster I sometimes use for more delicate items, like carb bodies, and I've also used it on some magnesium bits. It's pretty low flow rate, so takes a long time for anything larger. I've seen car bodies stripped with soda, but the blasters were really large units, and used a LOT of soda. Not something that would be practical for me. And it's not a reusable media, so you would go through a large volume of it if you used it much. But it does seem to be worth more investigation, if I could just get around to it.

Ken

fiatfan

VIP MEMBER

- Joined

- Aug 9, 2015

- Messages

- 524

This is the reason I´m getting the parts vapor blasted, this method does not affect the surface the same way that media blasting with glass beads do.Glass medis is OK for external surfaces. Never use sand or glass media on internal surfaces of the engine, primary or gearbox. Only use crushed walnut shells or plastic media for media blasting. Sand or glass media will enbed into the aluminum. When installed and raised to normal [hot] temps, the pores of the aluminum will open. The abrasive media trapped in the aluminum will then be released. This will then deposit the abrasive media into the oil. It will also end up inside the engine cylinders.

fiatfan

VIP MEMBER

- Joined

- Aug 9, 2015

- Messages

- 524

Interesting that plastic stuff. Could you give a good example of the engine paint you use? So I can compare with what is available over here....I also use glass beads regularly on aluminum bits, but didn't want to start the anti-glass bead wars all over again. I usually use glass beads to clean heads because the plastic beads and walnut shells don't seem aggressive enough to get the carbon deposits off. But they do work well for things like crankcases. I've used glass beads to clean engine parts for decades, and never had any negative effects from grit left in the castings. But I'm also very careful to clean them all very thoroughly in the solvent tank, followed by hot, soapy water, and blow out all the threads, passages, etc. with compressed air. I understand the logic of the arguments against that, but it's always worked for me. The best finish I've had on crankcases was from Excello plating, a local shop that got closed down decades ago by environmental regulations. They did a lot of aerospace and racing industry work, and I used them for plating, shot peening, crack inspection, and media blasting services. They were certified by all sorts of military and racing agencies. They cleaned my crankcases with glass beads followed by a low pressure blasting with steel shot. The shot closed up the surface pores and gave really nice semi-lustre finish. Now I just clean them myself and spray with a modern ceramic engine paint.

There's good information on plastic media here:

Plastic Blast Media | Paint Stripping | Blast Cleaning

Manufacturer of Plastic Media Abrasives for economical paint removal and blast cleaning. Excellent results on cars, trucks, airplanes, steel and aluminum.compomat.com

This is similar to the media I've been using:

Ken

lcrken

VIP MEMBER

- Joined

- Mar 15, 2009

- Messages

- 5,047

Interesting that plastic stuff. Could you give a good example of the engine paint you use? So I can compare with what is available over here....

This is what I use. Dupli-Color Engine Enamel Ceramic, part no. DE1650 CAST COAT ALUMINUM. Available here from auto parts stores and all sorts of on-line sites.

Ken

- Joined

- Nov 10, 2006

- Messages

- 1,538

I'm pretty sure that if the cases came painted from the factory they had failed the porosity test. The paint was use to seal them up?I´m having my cases vapor blasted, but first I have to get the paint off. The vapor blasting wont take the paint, it´s really tough. So are there any new good ways/liquids to get it off? It´s a 1973 Commando if that helps.

Could be wrong but its there in the back of my addled old brain.

Dave

fiatfan

VIP MEMBER

- Joined

- Aug 9, 2015

- Messages

- 524

Ok, never heard of a porosity test before, could that be the reason why some are painted and some not? At least it seems like that when you read earlier threads.I'm pretty sure that if the cases came painted from the factory they had failed the porosity test. The paint was use to seal them up?

Could be wrong but its there in the back of my addled old brain.

Dave

fiatfan

VIP MEMBER

- Joined

- Aug 9, 2015

- Messages

- 524

That particular one is not available in Europe as far as I can see, I´ll search for something similar, thanks.This is what I use. Dupli-Color Engine Enamel Ceramic, part no. DE1650 CAST COAT ALUMINUM. Available here from auto parts stores and all sorts of on-line sites.

View attachment 21023

Ken

- Joined

- Jun 25, 2004

- Messages

- 929

I used this to strip the head on my Combat. Somebody had painted it black with some really nasty paint at one time.

Circa 1850 Furniture Stripper (swingpaints.com)

It left the head looking like it was vapour blasted when I was done. Quick and very little elbow grease required.

Circa 1850 Furniture Stripper (swingpaints.com)

It left the head looking like it was vapour blasted when I was done. Quick and very little elbow grease required.

- Status

- Not open for further replies.

Similar threads

- Replies

- 10

- Views

- 535

- Replies

- 4

- Views

- 598

- Replies

- 30

- Views

- 3,576

- Replies

- 27

- Views

- 3,957

- Replies

- 22

- Views

- 2,287