- Joined

- Apr 15, 2009

- Messages

- 11,520

Is the stock handlebar kill switch normally closed and open when pressed?

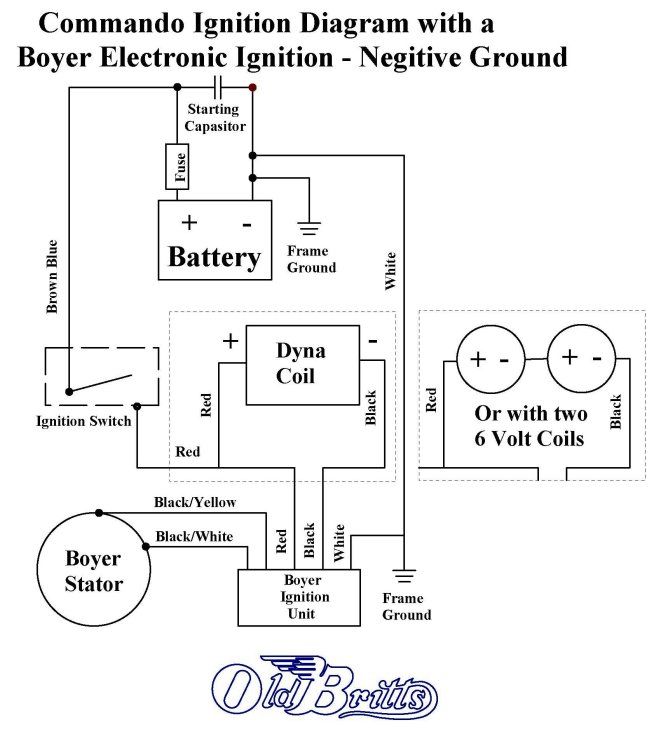

I assume on this diagram the kill switch would go between the ignition switch and coil?

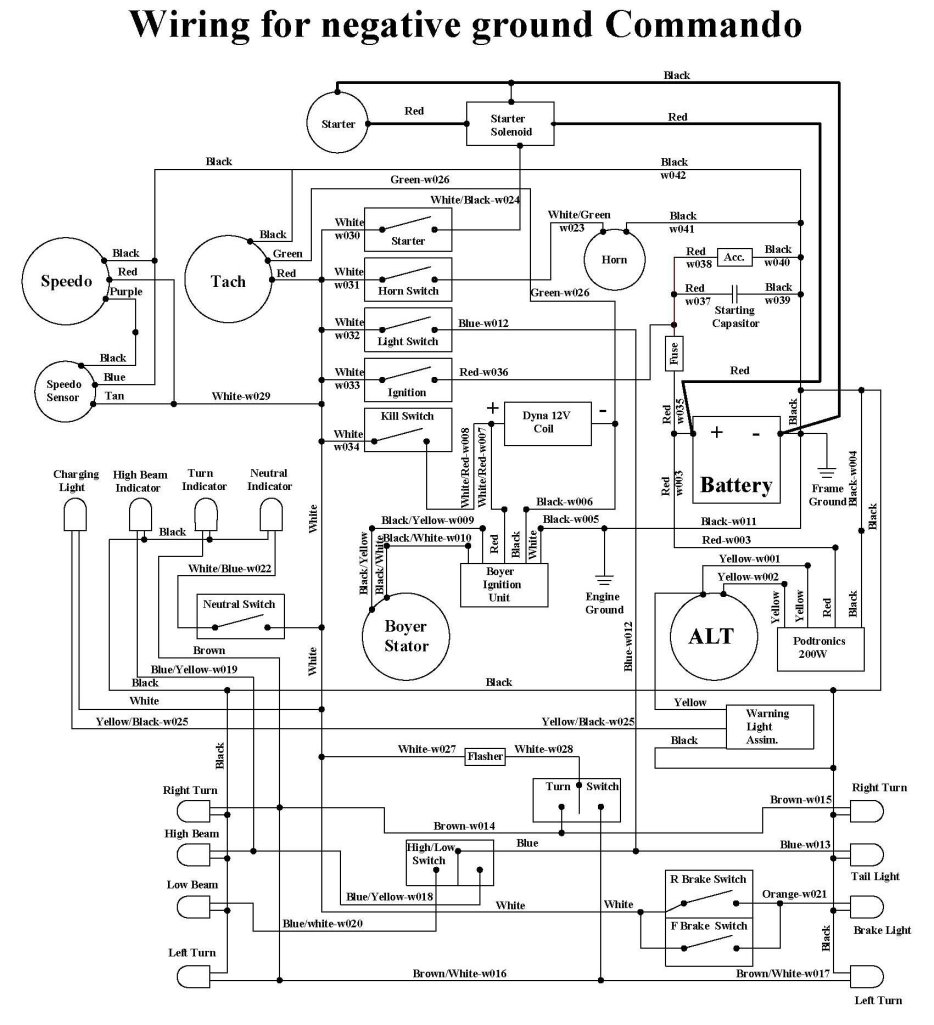

In this diagram, is the kill switch shown incorrectly in that the kill switch should be closed?

I assume on this diagram the kill switch would go between the ignition switch and coil?

In this diagram, is the kill switch shown incorrectly in that the kill switch should be closed?