- Joined

- Nov 26, 2009

- Messages

- 3,409

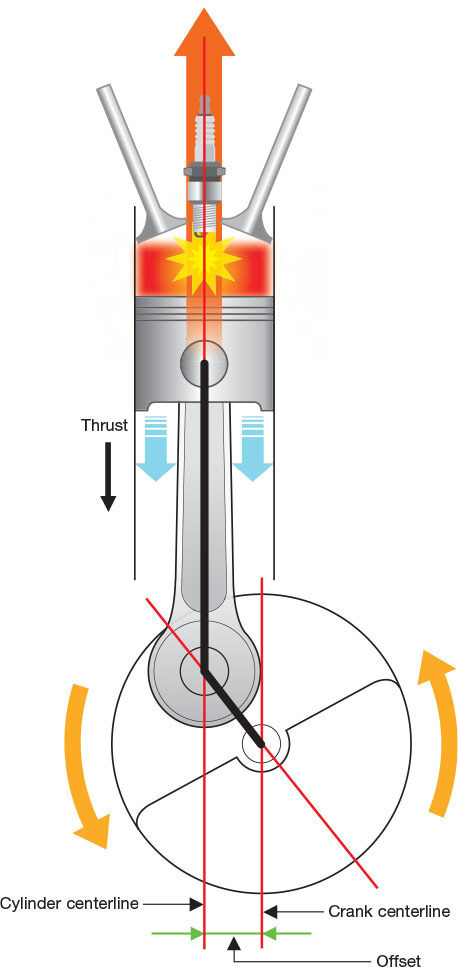

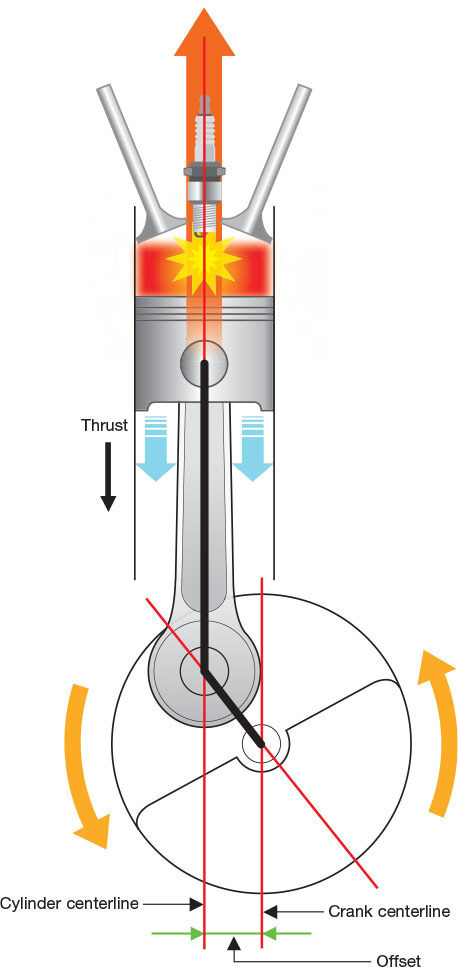

From what I've read the cylinders are supposed to be offset in the direction of crank rotation to reduce friction against the cylinder wall on the power stroke (increase HP & efficiency). It looks like Norton went the wrong direction when they offset the 650 cylinders to fit the larger 750 bore (they moved the cylinders away from the pushrod tunnels. Does anyone know exactly how much offset there is? (I'm rough measuring about 2mm). This is with early Commando/Atlas cases. Are Commando 750/850 cases the same? This may be correctable by milling the cases at an angle at the cyl base or using a tapered base gasket. The through bolts should still thread in OK as long as you don't go too far. See offset below.

Last edited: