- Joined

- Nov 26, 2009

- Messages

- 3,381

Norton balance factors can be confusing and range from 52 to 85%. Part of this wild variance problem is due to not specifying "wet" or "dry" - including or not including the weight of oil in the crank.

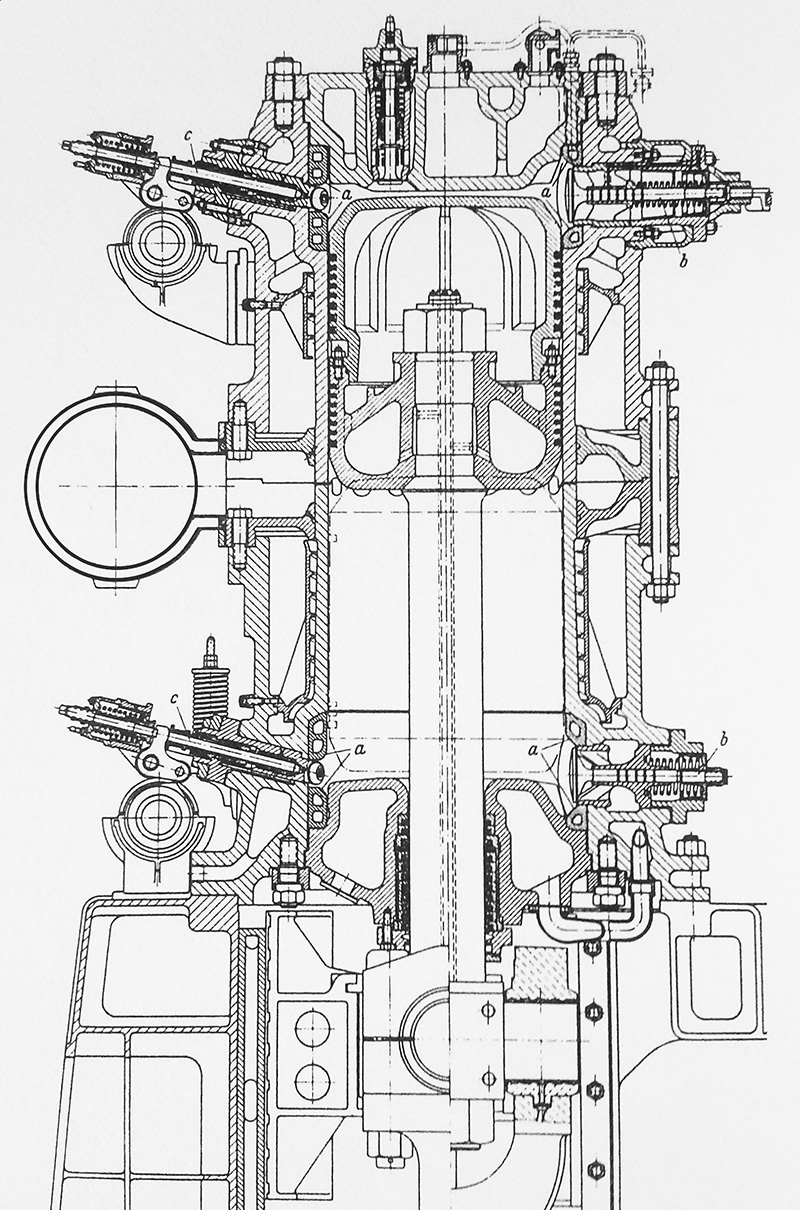

The best way to think about crank balance is to understand that with a 100% BF the Norton has perfect balance at TDC when the counterweight is opposite the rod/piston. But then the Norton is way out of balance when the piston is at the 1/2 way point of its stroke with the heavy counterweight sticking out to the side. So you have the choice of balancing the Norton when the rod is aligned with the bore center or at half stroke. Perfect balance at TDC eliminates the vertical shaking force. Perfect balance at 1/2 stroke eliminates horizontal shaking forces. But you can't have it both ways.

Calculating the perfect BF at the 1/2 way point of stroke is complicated. Figure it would include the bottom end of the rod as well as part of the rod that is out of line (angular) with the cylinder bore centerline. For simplicity lets assume that the rod big end weight along with 1/2 of the angular rod weight is less than the reciprocating weight (piston, pin, rod small end etc). It stands to reason that a compromise BF weight would be roughly mid point between the calculations. And thats why you hear of successfull BF factors generally in the 60 to 70% range (rubber mounts throwing in a wild card).

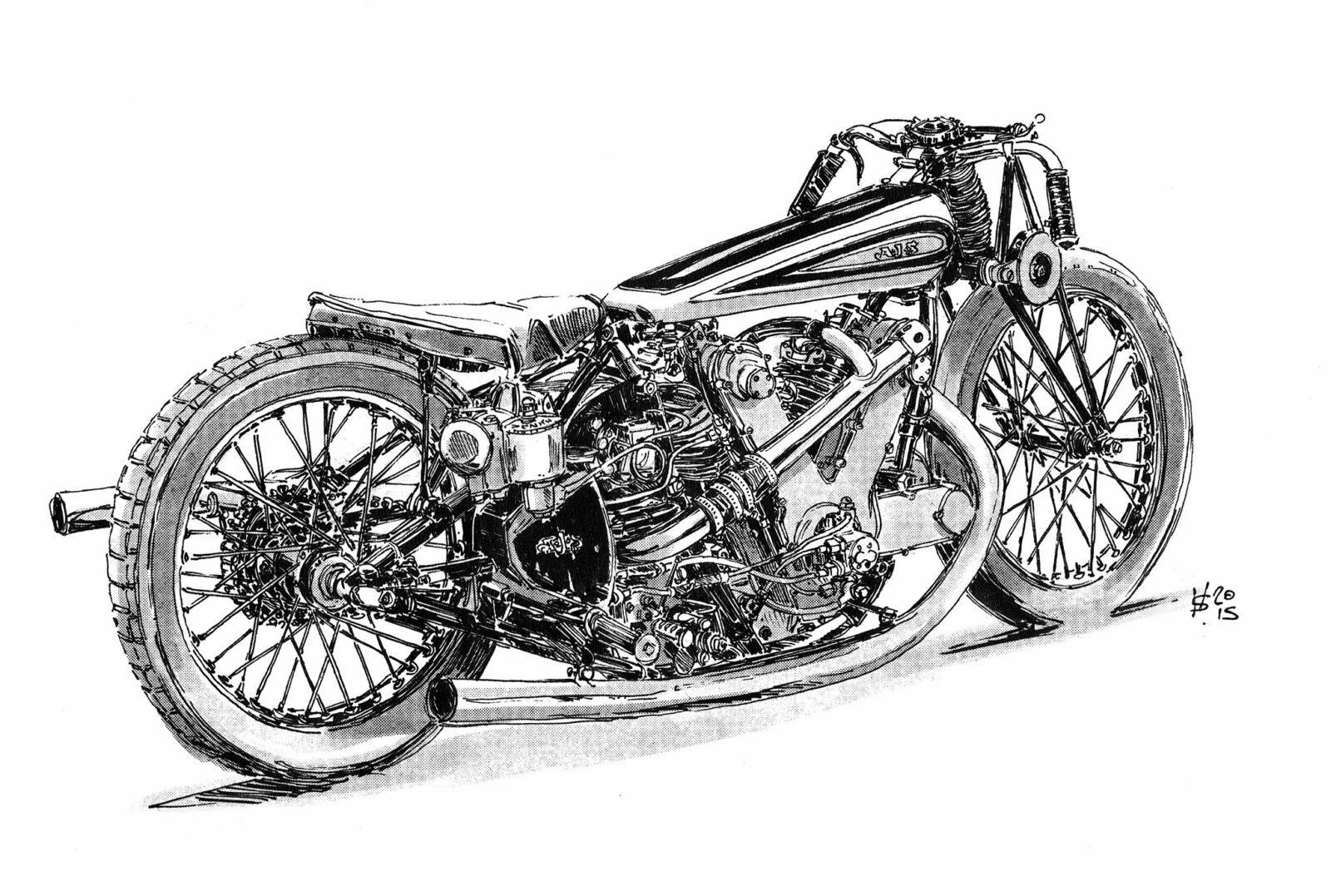

The norton is basically a side by side single and cannot be balanced to run smooth. The only way to smooth out the vibes is with rubber mounts or by reducing reciprocating weight (pistons and rod small ends etc) The 90 deg V twin Ducati on the other hand runs smooth because the counterbalance weights contribute to counteract the shaking forces throughout the stroke - eliminating shaking forces at TDC as well as at 1/2 stroke - 90 deg is the only twin corfiguration that provides perfect balance. But we cann't just take a bandsaw to our Nortons and rearrange the cylinders anyway we want.

So we keep messing with BFs, piston weights and rubber mounts and put up with the vibes when they are tolerable.

My own pet project (besides reducing reciprocating weight) is measuring vertical and horizontal vibration and finding a compromise between the two. I've measured it with a solid frame but not with isolastics and recommend BFs in the mid 60s percent range for solid frames (wet BF). I'd be interested if anyone would make a "scratch test" at 2000 4000 and 6000 RPM on a Commando frame with isolastics - But where on the frame as it might shake in different directions at different locations. The scratch test involves mounting a needle in a tiny tube like 1/32" ID K&S brass tubing (strapped to a weight) and tapping the needle momentarily to a polished piece of metal and then looking at the orbital shaped scratch under magnification (see scratch tool in photo). Its a difficult test but it can be achieved with a little development and enough attempts.

Also see this page:

www.accessnorton.com

www.accessnorton.com

The best way to think about crank balance is to understand that with a 100% BF the Norton has perfect balance at TDC when the counterweight is opposite the rod/piston. But then the Norton is way out of balance when the piston is at the 1/2 way point of its stroke with the heavy counterweight sticking out to the side. So you have the choice of balancing the Norton when the rod is aligned with the bore center or at half stroke. Perfect balance at TDC eliminates the vertical shaking force. Perfect balance at 1/2 stroke eliminates horizontal shaking forces. But you can't have it both ways.

Calculating the perfect BF at the 1/2 way point of stroke is complicated. Figure it would include the bottom end of the rod as well as part of the rod that is out of line (angular) with the cylinder bore centerline. For simplicity lets assume that the rod big end weight along with 1/2 of the angular rod weight is less than the reciprocating weight (piston, pin, rod small end etc). It stands to reason that a compromise BF weight would be roughly mid point between the calculations. And thats why you hear of successfull BF factors generally in the 60 to 70% range (rubber mounts throwing in a wild card).

The norton is basically a side by side single and cannot be balanced to run smooth. The only way to smooth out the vibes is with rubber mounts or by reducing reciprocating weight (pistons and rod small ends etc) The 90 deg V twin Ducati on the other hand runs smooth because the counterbalance weights contribute to counteract the shaking forces throughout the stroke - eliminating shaking forces at TDC as well as at 1/2 stroke - 90 deg is the only twin corfiguration that provides perfect balance. But we cann't just take a bandsaw to our Nortons and rearrange the cylinders anyway we want.

So we keep messing with BFs, piston weights and rubber mounts and put up with the vibes when they are tolerable.

My own pet project (besides reducing reciprocating weight) is measuring vertical and horizontal vibration and finding a compromise between the two. I've measured it with a solid frame but not with isolastics and recommend BFs in the mid 60s percent range for solid frames (wet BF). I'd be interested if anyone would make a "scratch test" at 2000 4000 and 6000 RPM on a Commando frame with isolastics - But where on the frame as it might shake in different directions at different locations. The scratch test involves mounting a needle in a tiny tube like 1/32" ID K&S brass tubing (strapped to a weight) and tapping the needle momentarily to a polished piece of metal and then looking at the orbital shaped scratch under magnification (see scratch tool in photo). Its a difficult test but it can be achieved with a little development and enough attempts.

Also see this page:

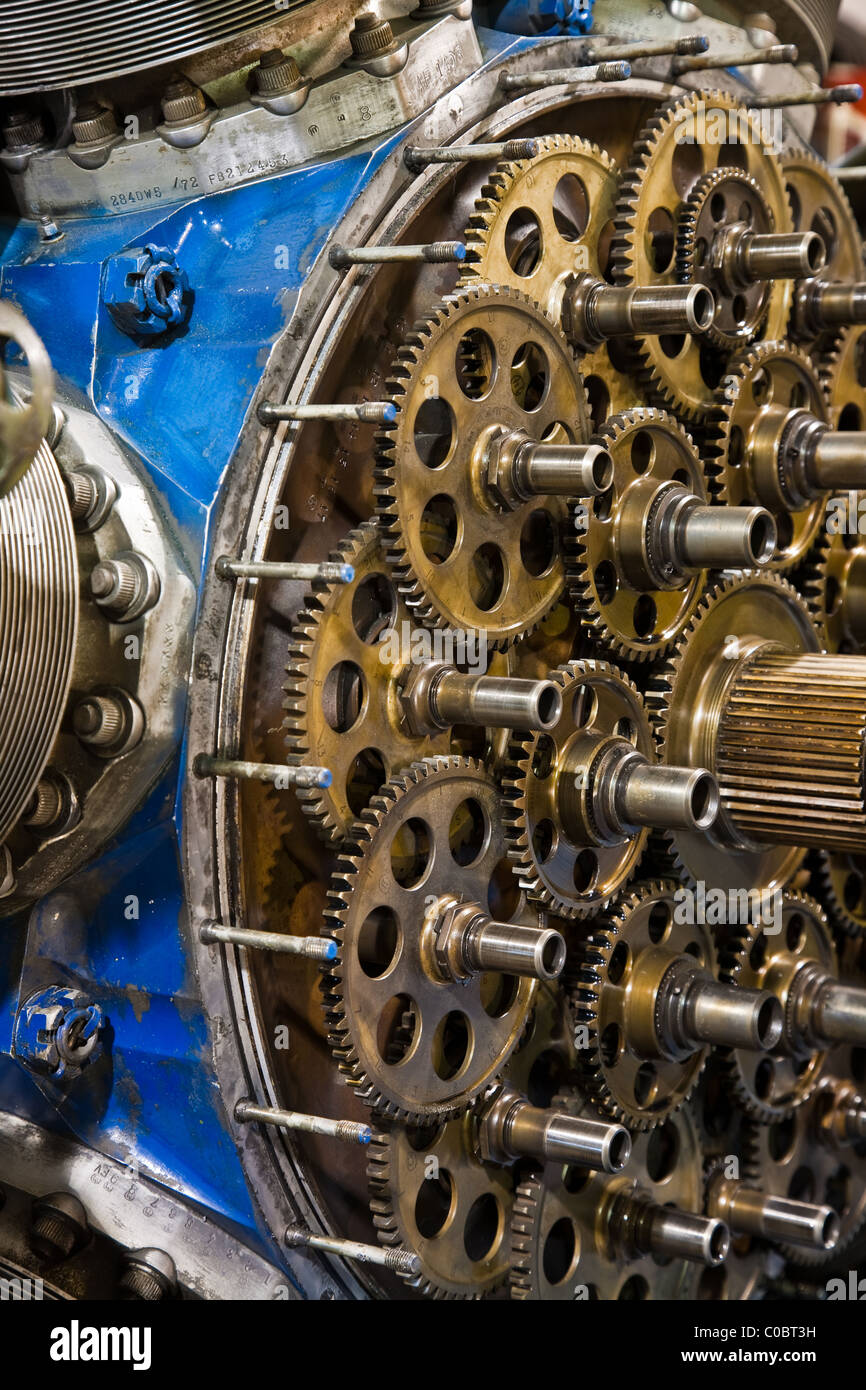

Balance factor scratch test tool

I decided to post this as a new topic. First of all - when people suggest a BF how do they qualify it? By the sensitivity of their butt and how well they remember how a Nort vibrated one day and they how it vibrated a few days later after they changed the balance factor? The first clue is that...

Last edited: