- Joined

- Feb 21, 2019

- Messages

- 1,067

74 commando -- there is a mounting hole in my RH support plate - it appears that at some point, there was something mounted there, and from some on-line pics, there is hardware filling the hole, so what gets mounted?

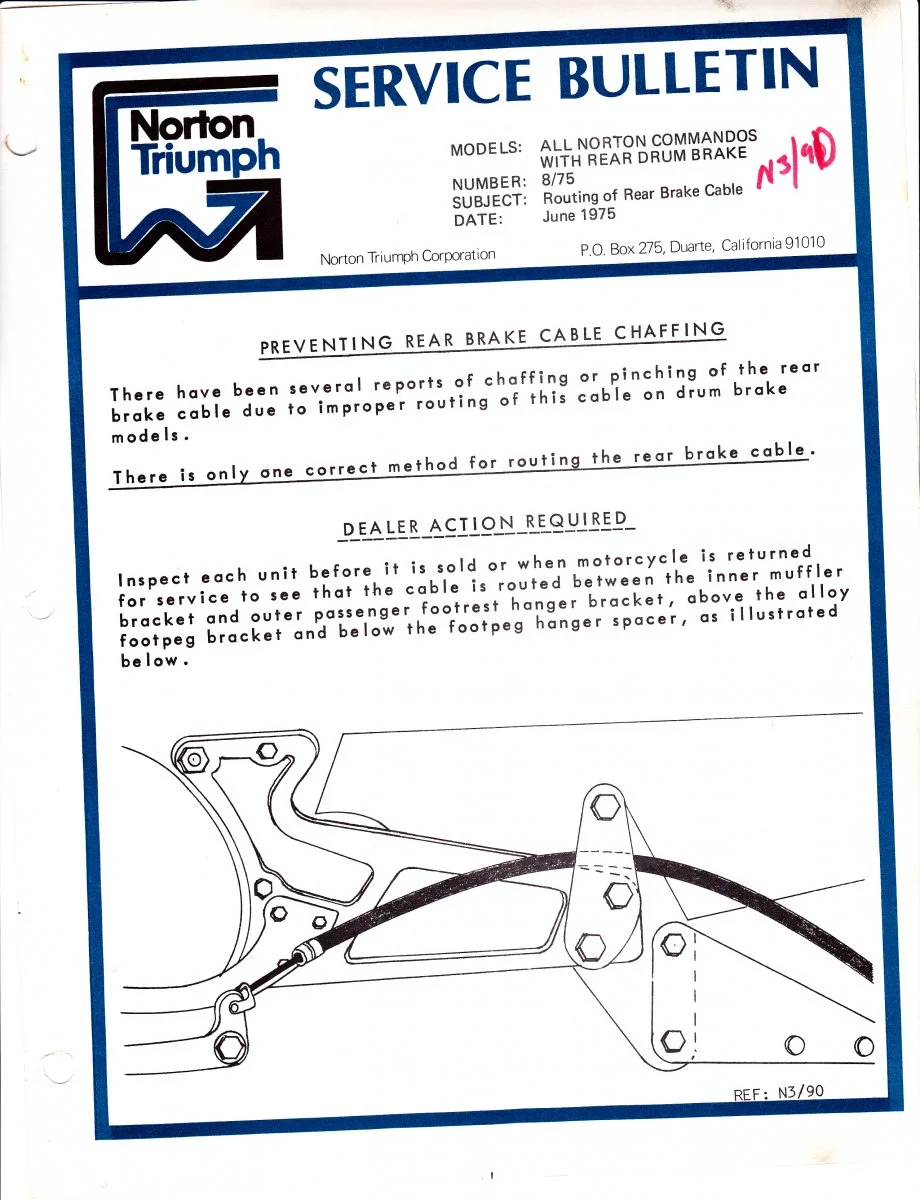

second question - my rear brake cable is routed through my rear muffler mount - don't think that's correct. I have seen a pic showing the cable routed below the LH support plate, and pics showing up above and behind the support plate. what's the correct routing? i'm leaning toward above and behind.

question #3 -- does anyone have a pic of the correct mounting of components on the rear frame bulkhead plate/component mounting plate - Zener diode, rectifier, capacitor, etc

I spent a few hours this AM figuring out the rear chain oiler - have most of the parts - everything but some sort of felt tubing or hose. someone removed it, cut the hose, and threw the parts into a box. question #4 -- how does this felt thing work? seems to me, it would seep oil and make a mess. as far as the oiler, what do most of you folks do? remove it and manually lube the chain, or keep the oiler mechanism?

too many hands in there over the years, just slapping things together without any thought as how it left the factory. things were changed, removed, modified, without thought. parts thrown into a box without the bag and tag approach. I've got boxes of pieces/parts, nuts and bolts, and i have no idea where some of this stuff goes. question #5 -- is there any publication details on how things get assembled. I can make out some details from the parts list manual. but actual routing of cables and such are somewhat unknown to me. TIA...

second question - my rear brake cable is routed through my rear muffler mount - don't think that's correct. I have seen a pic showing the cable routed below the LH support plate, and pics showing up above and behind the support plate. what's the correct routing? i'm leaning toward above and behind.

question #3 -- does anyone have a pic of the correct mounting of components on the rear frame bulkhead plate/component mounting plate - Zener diode, rectifier, capacitor, etc

I spent a few hours this AM figuring out the rear chain oiler - have most of the parts - everything but some sort of felt tubing or hose. someone removed it, cut the hose, and threw the parts into a box. question #4 -- how does this felt thing work? seems to me, it would seep oil and make a mess. as far as the oiler, what do most of you folks do? remove it and manually lube the chain, or keep the oiler mechanism?

too many hands in there over the years, just slapping things together without any thought as how it left the factory. things were changed, removed, modified, without thought. parts thrown into a box without the bag and tag approach. I've got boxes of pieces/parts, nuts and bolts, and i have no idea where some of this stuff goes. question #5 -- is there any publication details on how things get assembled. I can make out some details from the parts list manual. but actual routing of cables and such are somewhat unknown to me. TIA...

Last edited: