jimbo

VIP MEMBER

- Joined

- Sep 25, 2004

- Messages

- 1,966

What are the advantage's of fancy pancy pushrods? I would think the stockers are stiff and light enough?

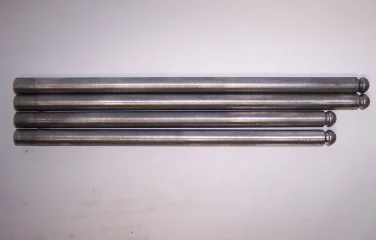

here we have a set of old school speed equipment rods

http://www.ebay.com/itm/322081011852?_t ... EBIDX%3AIT

heres a set aftermarket neato rods

http://www.ebay.com/itm/262709271773?_t ... EBIDX%3AIT

and here's the ole standard standby stockers

http://www.ebay.com/itm/381948334404?_t ... EBIDX%3AIT

here we have a set of old school speed equipment rods

http://www.ebay.com/itm/322081011852?_t ... EBIDX%3AIT

heres a set aftermarket neato rods

http://www.ebay.com/itm/262709271773?_t ... EBIDX%3AIT

and here's the ole standard standby stockers

http://www.ebay.com/itm/381948334404?_t ... EBIDX%3AIT