- Joined

- Nov 6, 2015

- Messages

- 400

There are two shortcomings with the 961 that have annoyed me the most. One is the idle which I've been investigating HERE

The other is oil in places it shouldn't be! Neither unfortunately can be fixed with a cable tie!

So this thread is going to deal with understanding the oil in the airbox issue and what can be done to mitigate it. The factory has tried a number of fixes, culminating in an ugly plastic box, which might have been acceptable if the problem had been solved. But the catch bottle serves as a reminder all is still not well!

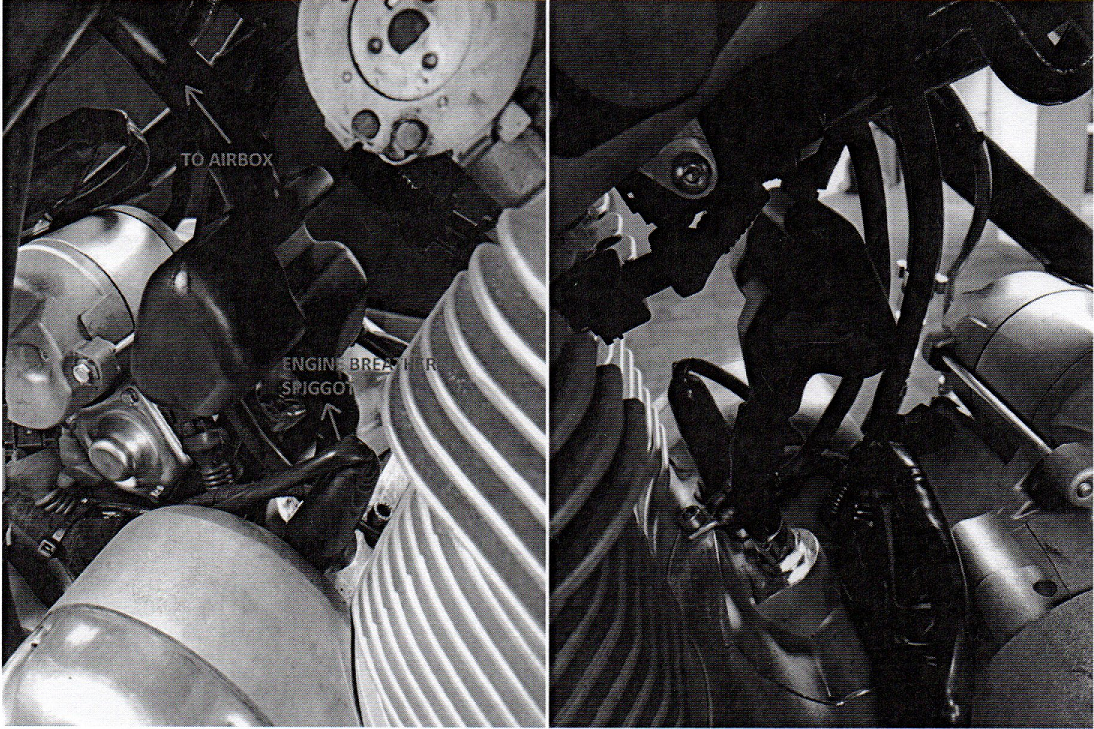

This is the original MKI oil breather system (taken from the factory manual).

With a sealed oil tank the cylinder head to oil tank pipe seems somewhat redundant, so there's no where for the gas to go but to the airbox via the rocker cover. Without an oil separator the airbox performed that role. Current fix is to block of the rocker cover and run the crankcase breather directly to the airbox with a large oil separator in between. Results vary...

Current fix is to block of the rocker cover and run the crankcase breather directly to the airbox with a large oil separator in between. Results vary...

So wanting to understand what goes where, I've removed all the breather pipes and replaced them with high temperature clear silicone tubing. To start with I've gone back to the MKI configuration but have inserted a small clear oil separator (to test) between the rocker box cover and what should be the airbox (vid to follow will make it clear).

My goal is to simplify the crankcase breathing system as much as possible and get rid of the catch bottle if possible. So I've shot a little video to show you all the current situation.

As you'll see the engine wants to breathe via the cylinder head to oil tank tube, but as it's sealed it can't.

Nothing new here nopdog and his mates figured this out a while back in this THREAD. But a video speaks a thousand words. The oil separator btw has virtually no resistance, it's very clear the engine would prefer to breath via the oil tank when given a choice. This is the preferable solution since the best place to collect the oil is surely the oil tank! But as the oil tank hasn't been designed to operate in this way oil will escape if you just try and vent the cap. But I have some ideas and a Fitter and Turner brother...

I haven't run the engine under load yet so a lot may change but I always enjoy these kind of threads. More importantly most of you know far more than me so maybe collectively we can come up with someone better than the current situation. There's no going back for me, I've removed and sealed off the airbox drain hole.

More importantly most of you know far more than me so maybe collectively we can come up with someone better than the current situation. There's no going back for me, I've removed and sealed off the airbox drain hole.

But I'll also be exploring other solutions that don't involve using the oil tank.

The other is oil in places it shouldn't be! Neither unfortunately can be fixed with a cable tie!

So this thread is going to deal with understanding the oil in the airbox issue and what can be done to mitigate it. The factory has tried a number of fixes, culminating in an ugly plastic box, which might have been acceptable if the problem had been solved. But the catch bottle serves as a reminder all is still not well!

This is the original MKI oil breather system (taken from the factory manual).

With a sealed oil tank the cylinder head to oil tank pipe seems somewhat redundant, so there's no where for the gas to go but to the airbox via the rocker cover. Without an oil separator the airbox performed that role.

So wanting to understand what goes where, I've removed all the breather pipes and replaced them with high temperature clear silicone tubing. To start with I've gone back to the MKI configuration but have inserted a small clear oil separator (to test) between the rocker box cover and what should be the airbox (vid to follow will make it clear).

My goal is to simplify the crankcase breathing system as much as possible and get rid of the catch bottle if possible. So I've shot a little video to show you all the current situation.

As you'll see the engine wants to breathe via the cylinder head to oil tank tube, but as it's sealed it can't.

Nothing new here nopdog and his mates figured this out a while back in this THREAD. But a video speaks a thousand words. The oil separator btw has virtually no resistance, it's very clear the engine would prefer to breath via the oil tank when given a choice. This is the preferable solution since the best place to collect the oil is surely the oil tank! But as the oil tank hasn't been designed to operate in this way oil will escape if you just try and vent the cap. But I have some ideas and a Fitter and Turner brother...

I haven't run the engine under load yet so a lot may change but I always enjoy these kind of threads.

But I'll also be exploring other solutions that don't involve using the oil tank.