hillbone

VIP MEMBER

- Joined

- Aug 24, 2009

- Messages

- 201

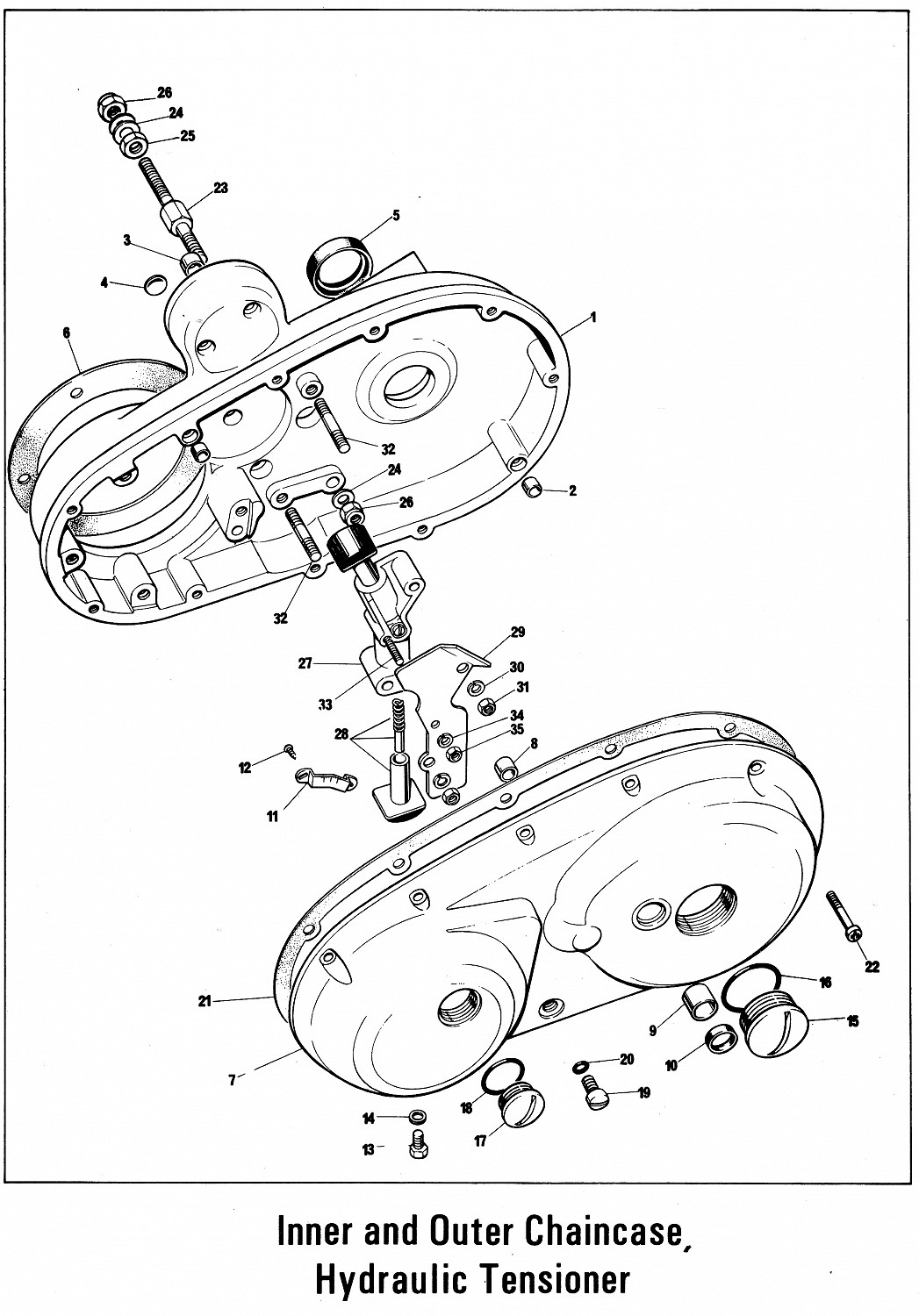

Gidday. I think i have finally resolved the horrible grinding , gnashing noise when from inside the primary when I hit the starter and the deep knocking noise at low revs when I blip the throttle. firstly the grinding noise was from some lateral movement in the anti backfire device. seems there was some wear in the bush in the inner cover allowing the anti device to move inwards towards the inner cover and the gears on the device were contacting the stainless steel plate that supports the hydraulic chain tensioner. I placed a couple of washers in the bush housing and this seems to have solved it.

The deep knocking noise is the 2 hydraulic chain tensioners bottoming out in their housings. When I blip the throttle you can see / hear them doing this. I have no idea why.

Questions.

1) Why have they decided to do this? I primed them with oil, which leaks out anyway thru the tiny holes. Will they self prime as time goes by? The other question is why do they not do this when the clutch plates are removed? something to do with load perhaps. New ones are $180AUD. would like to avoid the expense.

cheers Hiilbone

The deep knocking noise is the 2 hydraulic chain tensioners bottoming out in their housings. When I blip the throttle you can see / hear them doing this. I have no idea why.

Questions.

1) Why have they decided to do this? I primed them with oil, which leaks out anyway thru the tiny holes. Will they self prime as time goes by? The other question is why do they not do this when the clutch plates are removed? something to do with load perhaps. New ones are $180AUD. would like to avoid the expense.

cheers Hiilbone