An english wheel might be very useful to do the final finishing, since it could roll out the minor ripples that are otherwise difficult to remove.

But it wouldn't be very good at removing the initial dents ?, since it is more suited to gently rolling and shaping large areas of metal into curves.

Tackling the raw dents by rolling would likely stretch things out of shape, which would be difficult to recover from ?

nickguzzi said:

Gently, from the outside inwards.

That comment needs some further explanation, for clarity.

I was taught to work from inside the curve of the guard.

(not from the outside of the guard, which is how this can be interpreted !).

And to gently work around the edges OF THE DENT

Not too much at a time, so as not to stretch the metal.

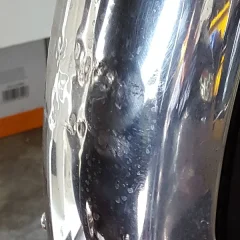

Quite deep dents can be gently massaged back into shape this way.

Tinmans mallet.

The head of these is wood, in case there is any doubt.