Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 20,659

I wrote in another thread that my T140 sprang a leak from the exhaust rocker box gasket. The leak was due to the fact that the rocker box gaskets were super brittle, they just snapped. In the area of the leak, the gasket had basically crushed and powdered.

It was also burning oil, oil was making its way down the rocker box through studs and instead of being sealed by the head gasket, oil was making its way into the combustion chamber. Again, the composite head gasket material around this area was crushed and uneven and in no way in a condition that you‘d expect to seal.

Thought I’d share some progress with y’all...

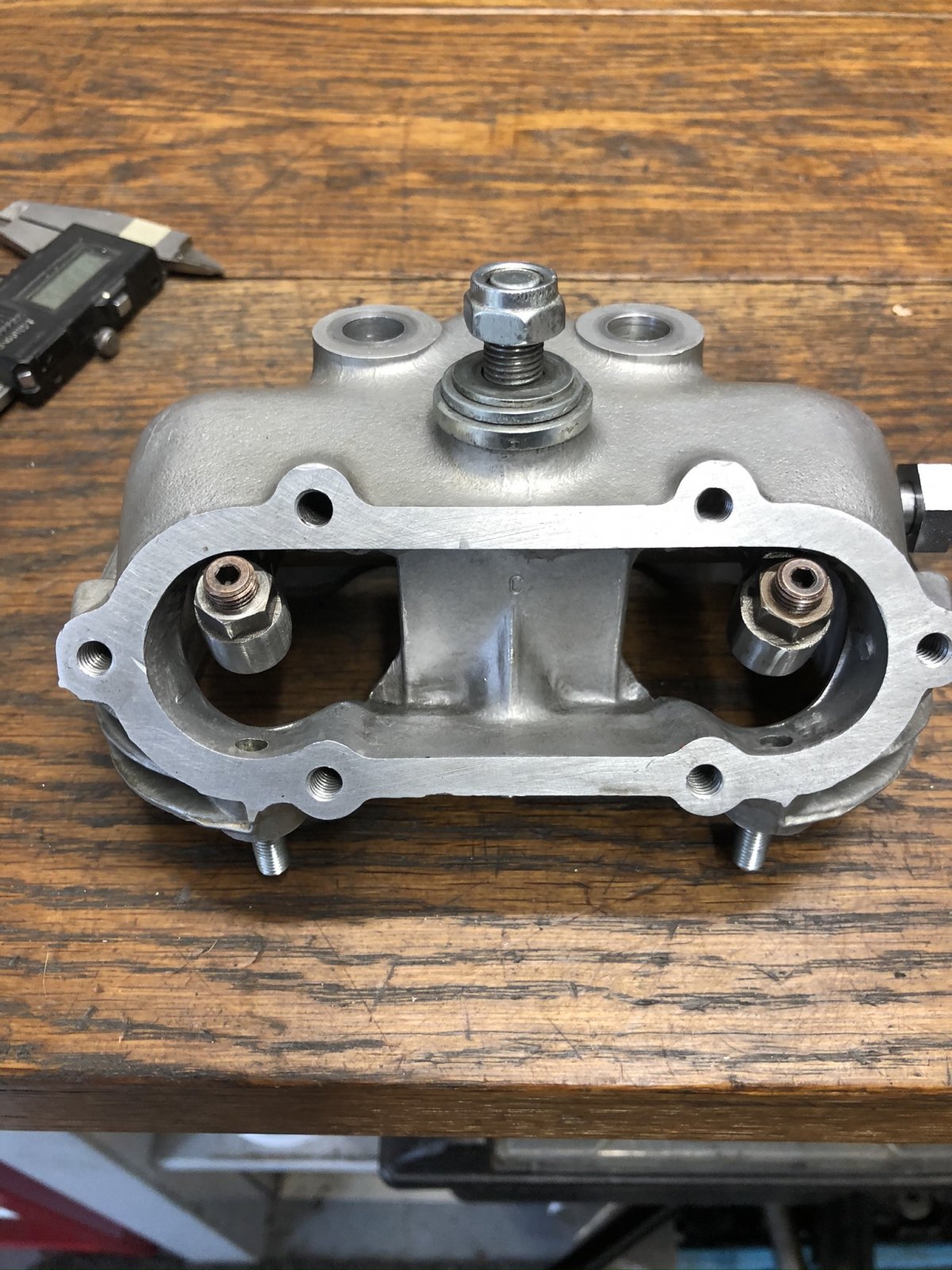

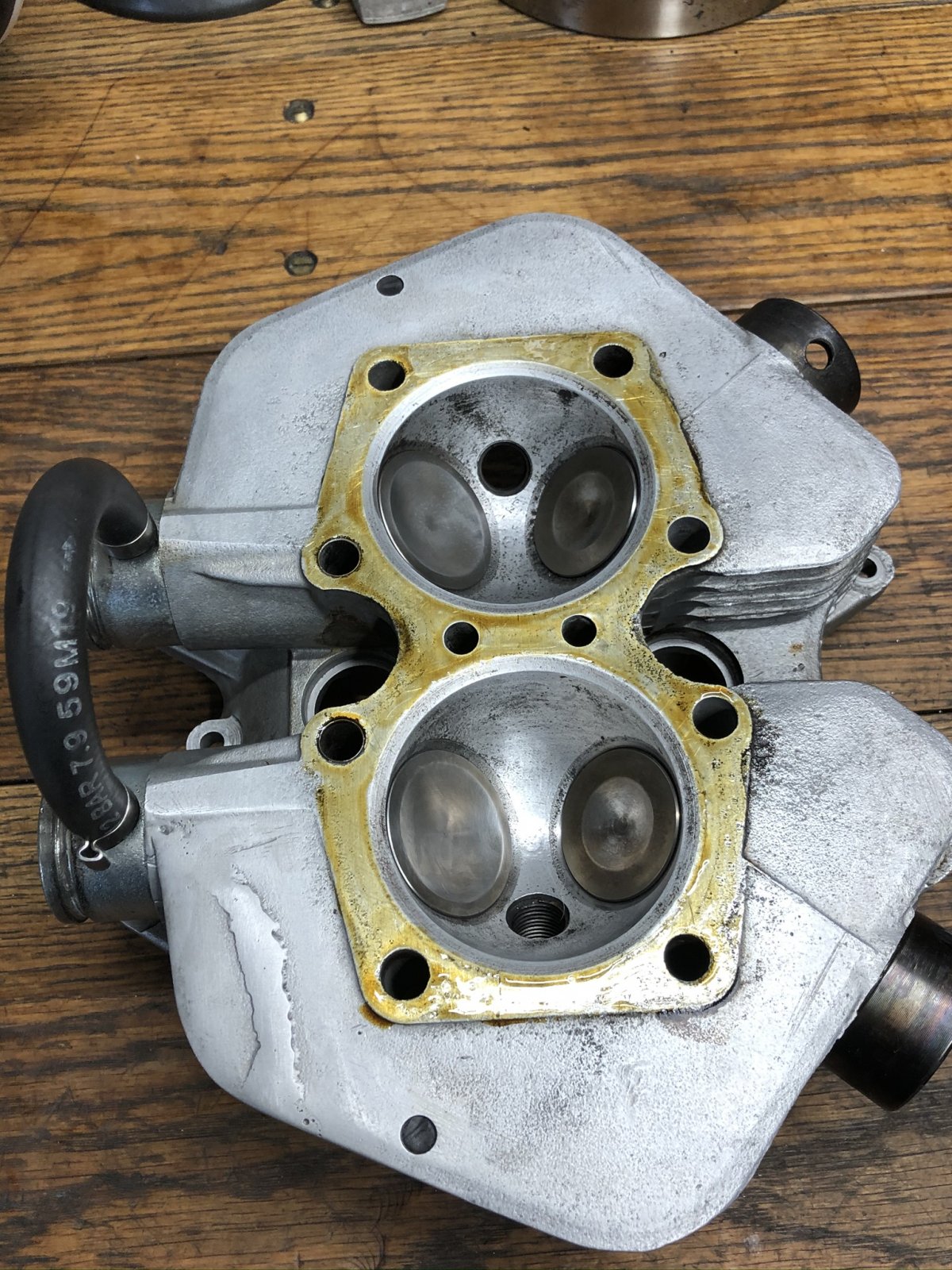

The pistons and combustion chambers were very carboned up. You can see how black the two front through studs are due to the oil...

But, when things were cleaned up, the pistons, bores, valves, guides, etc were all like new (which they are of course having only done 1200 miles)...

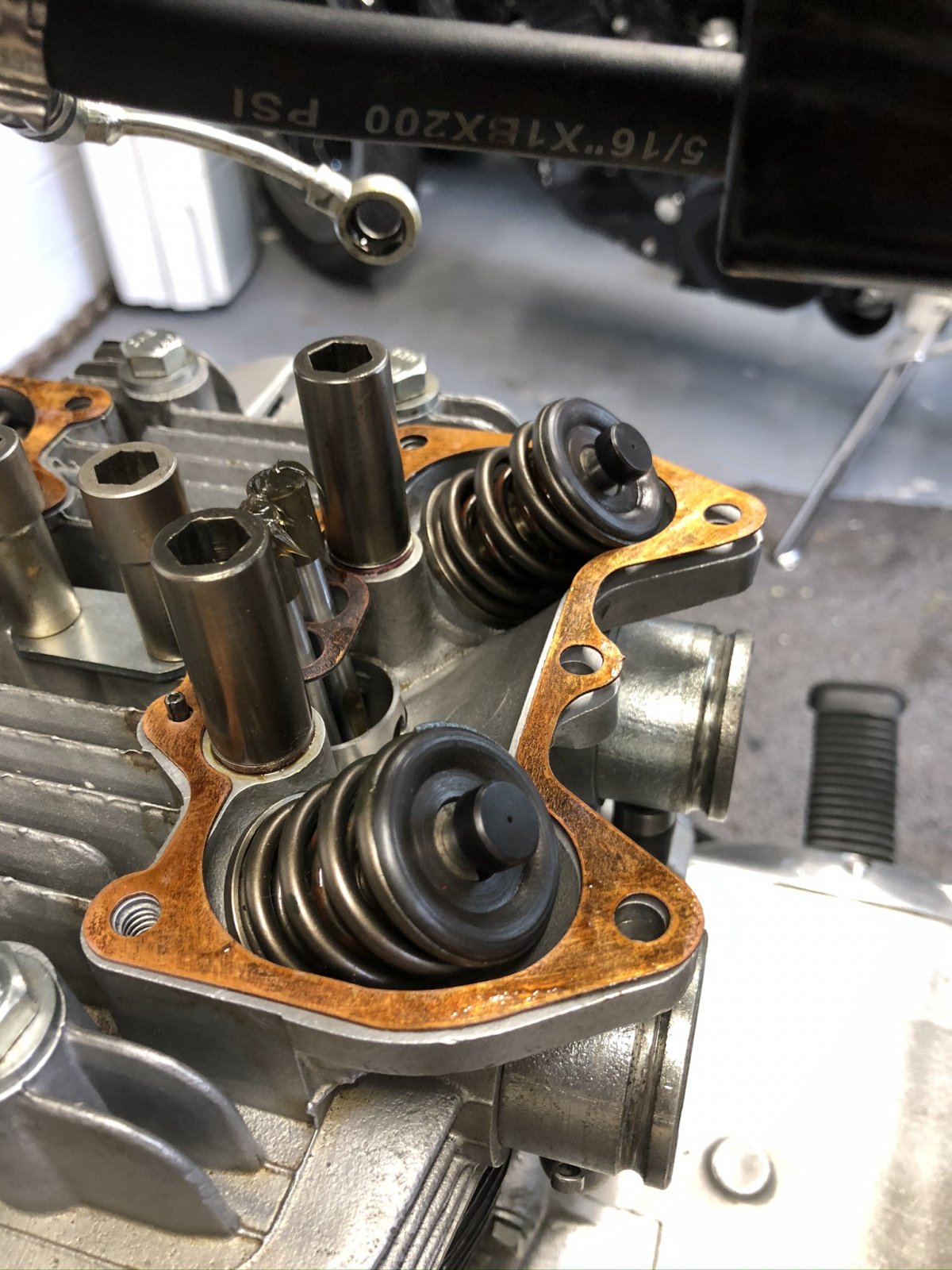

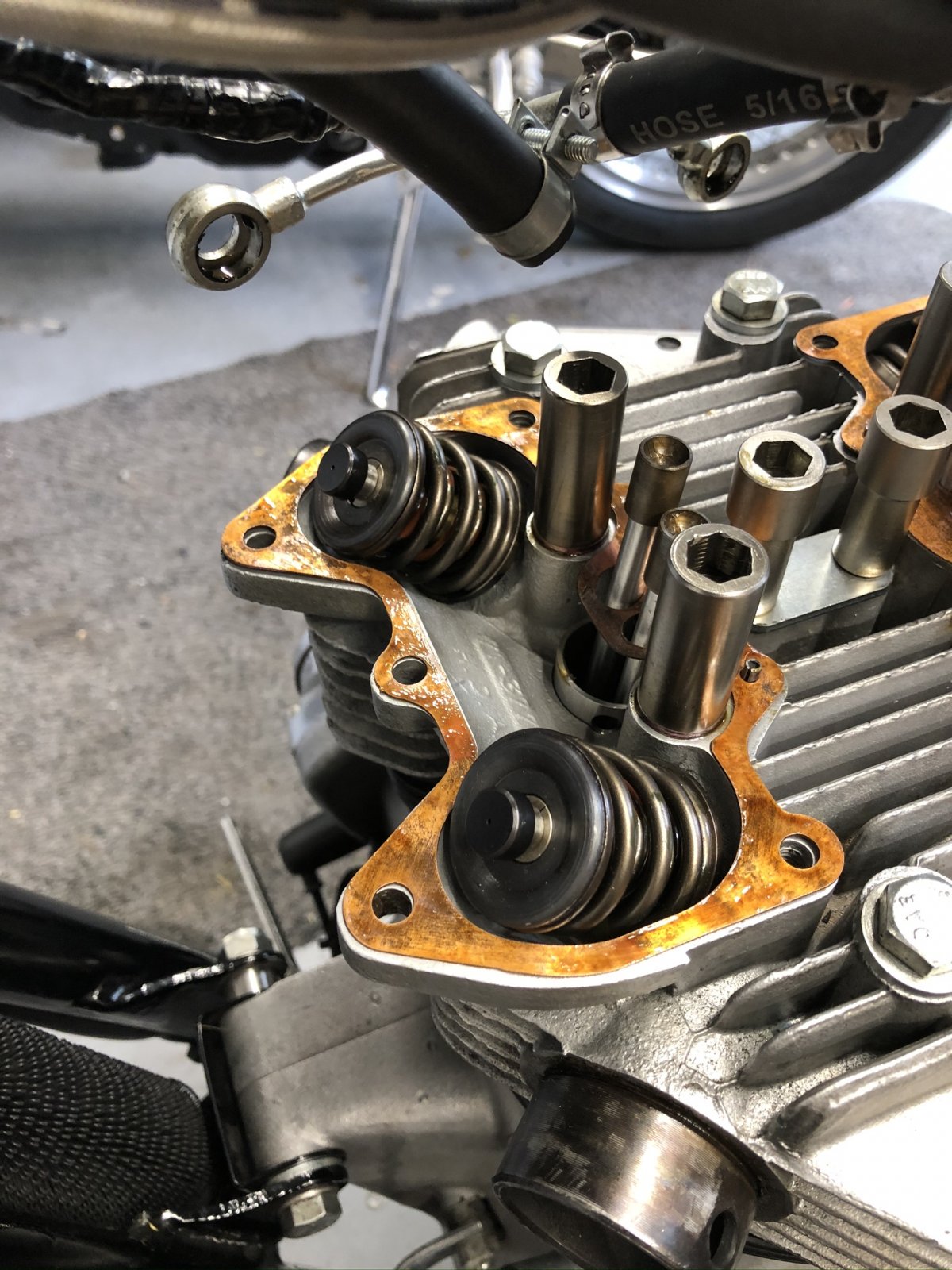

Using gasket goo recommended by Matchless some time ago, I dispensed with the base gasket, this and the copper head gasket tightened the squish to 0.34”-0.36” which I’m very happy with. The inlet valves were SO tight in the guides, meaning I had to drift them out! I suspected bent valves, but they weren’t. I struggle to see how this could have allowed proper valve control at high rpm, which I am blaming for the followers being marked, valve tips bruised and valves not seating correctly. I can only assume the engine builder thought ‘they’ll bed in’. I relieved the guides, fitted new followers and ground in the valves. The rocker shafts were clearly old, the rockers excellent, so I put new rocker shafts in too...

I know its hardly a race motor, but I couldn’t resist removing some excess metal off of the club footed rockers! Allen head mushroom tappets went in too...

Gotta love Wellseal...

The head itself was in great condition, no real seat recession, nice smooth squish area, no sign of grenading, etc. I had assumed bad seat recession as I thought the valves were to ‘high’. Turned out the pushrods were odd lengths. So I put NOS ones in I had in stock. And more Wellseal! I also used Wellseal on the copper head gasket after I’d annealed it...

I annealed the copper rocker box base gaskets and, yup, used Wellseal! I put Dowty washers under the through stud nuts to stop the oil. I faced up the bruised valve ends, and fitted posh lash caps, just cos I had them in stock...

It was also burning oil, oil was making its way down the rocker box through studs and instead of being sealed by the head gasket, oil was making its way into the combustion chamber. Again, the composite head gasket material around this area was crushed and uneven and in no way in a condition that you‘d expect to seal.

Thought I’d share some progress with y’all...

The pistons and combustion chambers were very carboned up. You can see how black the two front through studs are due to the oil...

But, when things were cleaned up, the pistons, bores, valves, guides, etc were all like new (which they are of course having only done 1200 miles)...

Using gasket goo recommended by Matchless some time ago, I dispensed with the base gasket, this and the copper head gasket tightened the squish to 0.34”-0.36” which I’m very happy with. The inlet valves were SO tight in the guides, meaning I had to drift them out! I suspected bent valves, but they weren’t. I struggle to see how this could have allowed proper valve control at high rpm, which I am blaming for the followers being marked, valve tips bruised and valves not seating correctly. I can only assume the engine builder thought ‘they’ll bed in’. I relieved the guides, fitted new followers and ground in the valves. The rocker shafts were clearly old, the rockers excellent, so I put new rocker shafts in too...

I know its hardly a race motor, but I couldn’t resist removing some excess metal off of the club footed rockers! Allen head mushroom tappets went in too...

Gotta love Wellseal...

The head itself was in great condition, no real seat recession, nice smooth squish area, no sign of grenading, etc. I had assumed bad seat recession as I thought the valves were to ‘high’. Turned out the pushrods were odd lengths. So I put NOS ones in I had in stock. And more Wellseal! I also used Wellseal on the copper head gasket after I’d annealed it...

I annealed the copper rocker box base gaskets and, yup, used Wellseal! I put Dowty washers under the through stud nuts to stop the oil. I faced up the bruised valve ends, and fitted posh lash caps, just cos I had them in stock...

Last edited: