- Joined

- Jun 24, 2009

- Messages

- 63

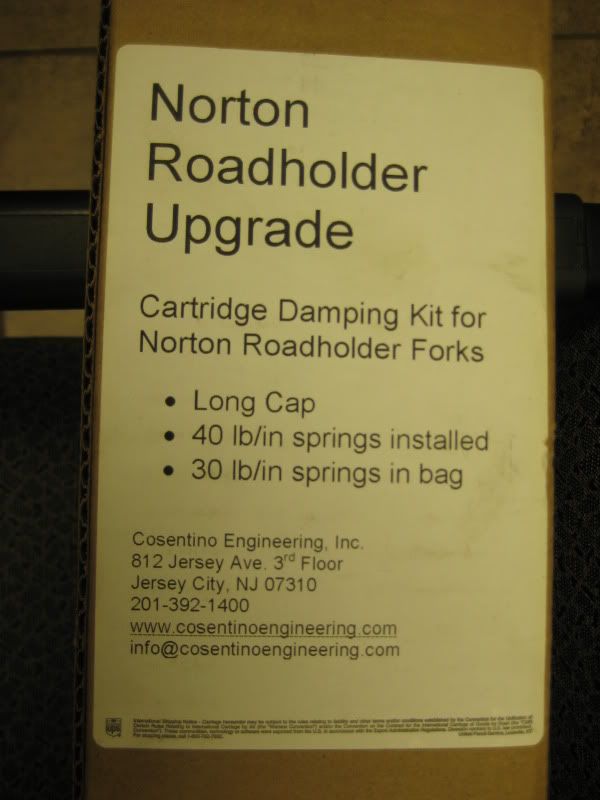

Before ordering, I could find very little information or opinions on the Cosentino fork mod and figured I would post what I've learned so far for those that may be on the fence or just curious. I have several older British bikes (relative to this '73 850) and with all my efforts (stock & modified), the front ends are marginal, at best and that maybe overly optimistic. Although I would not admit it to most folks and especially, to my wife, it is rather disappointing to spend all that time, labor and money on a bike only to find that the handling is sub-standard. It detracts from the rest of the bike as just looking good isn't good enough. The '73 front end "appears" more modern than my older bikes but internally, not much, if any, better. With this Norton and the way I plan to ride it, I vowed to do whatever necessary to make it handle where I don't feel handi-capped when riding with others. Someone handily posted a link for Cosentino Engineering on the forum, so, I contacted Chris Cosentino and after discussing with him (fork length, instrument mounting, spring rates), I placed an order. It took a little longer to recieve than what I had hoped (and that's always the case) but in the scheme of things and for what I recieved, it wasn't that long and admittedly, I was anxious (still am). As it worked out, I'm still waiting on wheel parts. At any rate, this is what I have observed so far.

Top caps available long for standard instrument mounting or short for none.

Well packaged...included thermally stabile fork oil, installation tools and detailed installation instructions. ....I ordered two sets of different rate springs (inexpensive option). Cartridge unit with springs, caps etc. weigh 2 lbs, stock parts weigh 3 lbs., if it matters. The cartridges are modified versions for a modern, comparable-weight, sport bike.

Compression dampening adjustment incorporated into the lower cartridge bolt (sealing washers included).

Once the cartridge is installed in the fork and the 4-3/4 oz. of fork oil is loaded, the tubular installation tool is, also, used to prime the cartridges. Basically, you stroke the Damper Rod up & down until fork oil is pumped out of the weep hole of the installation tool. Once completely primed with oil, that's when I started to realize how nice these units really are. Extremely smooth action in both directions and no dampening "gap" or lag between the up & down transitions.

Due to the fact that I had a fork brace installed, I had to deviate from the instructions slightly whereas the instructions deal with each individual fork leg, I had to take each leg to the next step as a unit. The included "installation wrench" is, also, used to support the Damper Rod during installation. When the Damper Rod is at the top of the stroke (topping out)...it doesn't actually top out but instead, it goes up against an internal spring in the cartridge (another big plus). No metal to metal banging. With the firm "top out spring" compressed slightly, the wrench holds the Damper Rod for the next step.

This picture shows both units installed with the spring pre-load set on the timing side fork. I had to guess at the pre-load as I have no wheels built yet to check. Brass plugs are used to cover the rebound adjustment screws.

Everything nipped up.

Additional front-end enhancements.

As far as the kit, it is very complete and once you go through the installation steps, it is obviously well thought out. Coming from a machining/manufacturing background, I am qualified to say that the quality of the machined bits (especially the thread qualities) are spot on. I'm so used to buying new parts that come in like re-workable cores, that it was refreshing to have everything work straight out of the box. Based on what I've seen to date, would I do it again? Absolutely.

Once I have wheels built and installed, I'm going to pull the springs out of the forks to confirm slider travel due to the fork brace, re-install springs, adjust the static pre-load (sag with rider on-board), focus on wheel alignment. Once I'm to the point of tweaking out the compression/rebound/springs, I'll follow up with a riding report.

Z

Top caps available long for standard instrument mounting or short for none.

Well packaged...included thermally stabile fork oil, installation tools and detailed installation instructions. ....I ordered two sets of different rate springs (inexpensive option). Cartridge unit with springs, caps etc. weigh 2 lbs, stock parts weigh 3 lbs., if it matters. The cartridges are modified versions for a modern, comparable-weight, sport bike.

Compression dampening adjustment incorporated into the lower cartridge bolt (sealing washers included).

Once the cartridge is installed in the fork and the 4-3/4 oz. of fork oil is loaded, the tubular installation tool is, also, used to prime the cartridges. Basically, you stroke the Damper Rod up & down until fork oil is pumped out of the weep hole of the installation tool. Once completely primed with oil, that's when I started to realize how nice these units really are. Extremely smooth action in both directions and no dampening "gap" or lag between the up & down transitions.

Due to the fact that I had a fork brace installed, I had to deviate from the instructions slightly whereas the instructions deal with each individual fork leg, I had to take each leg to the next step as a unit. The included "installation wrench" is, also, used to support the Damper Rod during installation. When the Damper Rod is at the top of the stroke (topping out)...it doesn't actually top out but instead, it goes up against an internal spring in the cartridge (another big plus). No metal to metal banging. With the firm "top out spring" compressed slightly, the wrench holds the Damper Rod for the next step.

This picture shows both units installed with the spring pre-load set on the timing side fork. I had to guess at the pre-load as I have no wheels built yet to check. Brass plugs are used to cover the rebound adjustment screws.

Everything nipped up.

Additional front-end enhancements.

As far as the kit, it is very complete and once you go through the installation steps, it is obviously well thought out. Coming from a machining/manufacturing background, I am qualified to say that the quality of the machined bits (especially the thread qualities) are spot on. I'm so used to buying new parts that come in like re-workable cores, that it was refreshing to have everything work straight out of the box. Based on what I've seen to date, would I do it again? Absolutely.

Once I have wheels built and installed, I'm going to pull the springs out of the forks to confirm slider travel due to the fork brace, re-install springs, adjust the static pre-load (sag with rider on-board), focus on wheel alignment. Once I'm to the point of tweaking out the compression/rebound/springs, I'll follow up with a riding report.

Z