i have just stripped my MK3 primary to fit a new primary chain. whilst stripping the bike i noticed a bit of play in the clutch hub bearing. i know a 6007 C2 bearing should be fitted but i cannot find anyone who supplies a C2. would there be an issue fitting a std 6007 bearing??

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Clutch hub bearing

- Thread starter Tripler

- Start date

- Joined

- Nov 4, 2007

- Messages

- 1,448

6007-2Z/C2ELHT23 35x62x14mm SKF Single Row Deep Groove Ball Bearing

6007-2Z/C2ELHT23 35x62x14mm SKF Single Row Deep Groove Ball BearingSingle Row Deep Groove Ball BearingMetric, Bearing, Bearing Steel, Metal Shield On Both Sides, -50 To +140 DegC Grease, C2 E ClearancePlease Note: If selected brand is not available a suitable alternative will be supplied in...

You could find it there ....

Great thanks

6007-2Z/C2ELHT23 35x62x14mm SKF Single Row Deep Groove Ball Bearing

6007-2Z/C2ELHT23 35x62x14mm SKF Single Row Deep Groove Ball BearingSingle Row Deep Groove Ball BearingMetric, Bearing, Bearing Steel, Metal Shield On Both Sides, -50 To +140 DegC Grease, C2 E ClearancePlease Note: If selected brand is not available a suitable alternative will be supplied in...bepltd.com

You could find it there ....

marshg246

VIP MEMBER

- Joined

- Jul 12, 2015

- Messages

- 5,121

Two questions.i have just stripped my MK3 primary to fit a new primary chain. whilst stripping the bike i noticed a bit of play in the clutch hub bearing. i know a 6007 C2 bearing should be fitted but i cannot find anyone who supplies a C2. would there be an issue fitting a std 6007 bearing??

1) Where did the C2 requirement come from?

2) What's wrong with bearing AN sells?

- Joined

- Nov 20, 2004

- Messages

- 20,582

The factory manual.1) Where did the C2 requirement come from?

"One dot bearing" = C2.

Last edited:

- Joined

- Dec 3, 2012

- Messages

- 3,727

2) What's wrong with bearing AN sells?

It appears to be a cheap CN open bearing ?

If so it would have a small but noticeable amount of axial wobble at the drum OD, much less than a C3 but more than a C2. (fully sealed 2RS being a viable improvement for fit and forget) C2 - C0/CN - C3 - C4 - C5

#

The clutch bearing is only working when the bike is in gear with the clutch lever pulled in. (Engine running) so not overtaxed in normal running.

- Joined

- Dec 3, 2012

- Messages

- 3,727

Disclaimer. The reason I know the wobble difference between the C0/CN and C3 is due to forgetting about the specified C2 and put a C3 in (yikes for wobble) so put a standard bearing in which was reasonable as far as wobble but noticeable. (but perhaps about the same as the original open bearing that had been removed)

I have a still gathering dust CNW clutch hub (Thanks Matt for the AU$25 refund when it came time to mail it and it was less that expected) to fit along with a 4 + 1 Barnett clutch pack from member 'Racing Norton via eBay so will strip the primary and find a correct 6007 C2 in 2RS sealed form when I get home from work in December.

I have a still gathering dust CNW clutch hub (Thanks Matt for the AU$25 refund when it came time to mail it and it was less that expected) to fit along with a 4 + 1 Barnett clutch pack from member 'Racing Norton via eBay so will strip the primary and find a correct 6007 C2 in 2RS sealed form when I get home from work in December.

marshg246

VIP MEMBER

- Joined

- Jul 12, 2015

- Messages

- 5,121

At least in the picture on the AN web site they are FAG bearings, not Chinese bearings. IMHO, open is fine for standard primaries. Of course for belt drives, sealed is required.It appears to be a cheap CN open bearing ?

If so it would have a small but noticeable amount of axial wobble at the drum OD, much less than a C3 but more than a C2. (fully sealed 2RS being a viable improvement for fit and forget) C2 - C0/CN - C3 - C4 - C5

#

The clutch bearing is only working when the bike is in gear with the clutch lever pulled in. (Engine running) so not overtaxed in normal running.

Last edited:

marshg246

VIP MEMBER

- Joined

- Jul 12, 2015

- Messages

- 5,121

Just re-confirmed with AN that they do not supply Chinese bearings.It appears to be a cheap CN open bearing ?

If so it would have a small but noticeable amount of axial wobble at the drum OD, much less than a C3 but more than a C2. (fully sealed 2RS being a viable improvement for fit and forget) C2 - C0/CN - C3 - C4 - C5

#

The clutch bearing is only working when the bike is in gear with the clutch lever pulled in. (Engine running) so not overtaxed in normal running.

- Joined

- Dec 3, 2012

- Messages

- 3,727

Just re-confirmed with AN that they do not supply Chinese bearings.

I never mentioned China, I said cheap.

It still looks to be a CN clearance bearing based off the numbers so not a C2 until informed otherwise and can see no point in using an open bearing (these days) for various reasons in general.

marshg246

VIP MEMBER

- Joined

- Jul 12, 2015

- Messages

- 5,121

You said: "... cheap CN open bearing". CN also = China! Had you said "... cheap CN clearance open bearing" I would not have assumed China.I never mentioned China, I said cheap.

It still looks to be a CN clearance bearing based off the numbers so not a C2 until informed otherwise and can see no point in using an open bearing (these days) for various reasons in general.

FAG bearings are not cheap - in general, they cost at least double what equivalent cheap bearings cost! Here's a cheap 6007-2RS CN clearance made in China bearing (less than $5 delivered): Amazon product ASIN B072LBSY7V

marshg246

VIP MEMBER

- Joined

- Jul 12, 2015

- Messages

- 5,121

Best I can tell, bearings from the 1970s did not have industry standard markings, were marked differently by different manufacturers, and were often made of different materials than today. A 6007 would have the same dimensions as today, but I haven't found anything that says that a "one-dot" from the 1970s equals a C2 today. Do you know what manufacturer the workshop manual was referring to and/or the actual specifications that represented a "one-dot"?The factory manual.

"One dot bearing" = C2.

Not sure anyone this really matters as BSA and Triumph used a more robust, but more wobbly system that seemingly lasted for ever.

- Joined

- Nov 20, 2004

- Messages

- 20,582

Best I can tell, bearings from the 1970s did not have industry standard markings, were marked differently by different manufacturers, and were often made of different materials than today.

but I haven't found anything that says that a "one-dot" from the 1970s equals a C2 today. Do you know what manufacturer the workshop manual was referring to and/or the actual specifications that represented a "one-dot"?

I'm not aware of the dot system applying to any particular British bearing manufacturer.

As with most things this one dot/C2 bearing has been discussed before, several times.

Clutch basket play and ? gearbox problems on MK3.

Yesterday I fitted a new clutch centre and bearing to my clutch on my Commando MK3, as the gearbox was difficult to select gears and it was not possible to select neutral whilst the engine was running. I also have a cross shaft and cross shaft bush on order to be fitted next week. I fitted...

Clutch wobble

Here’s a wee Mpeg I took of the Commando today after putting things back together (again) The quality ain’t brilliant and it looks like a kinda strobe effect slowing things down but you can clearly see the wobble of the clutch basket. http://s14.photobucket.com/albums/a340/ ...

How Much Wobble?

I am re-manufacturing a 1975 Mk III roadster, I am now doing logistics for the primary drive. The first item I have replaced is the bearing between the clutch basket and the clutch center. I purchased a Chinese made bearing, put it in using thermal methods (no hammering on the bearing). I let it...

Clutch basket wobble

My clutch basket is not very solid with respect to the gearbox output shaft - wobbles. The clutch center on the other hand is nice and solid. The only thing keeping the basket in place is the bearing and that's fairly new. I expect this is normal, but has anyone found a way to resolve this -...

Andover, as far as I'm aware supplies the standard 6007 bearing even though they should know it's a C2.

Clutch bearing/clutch centre fit?

Where is the information that specs the 060750 as a C2 or 'one dot'? Go back one page.

13th April 1970 drawing for 06-0750 says "one dot" and a later amendment, dated 9th July 1971, says "C2".

Last edited:

marshg246

VIP MEMBER

- Joined

- Jul 12, 2015

- Messages

- 5,121

Interesting since the MK3 workshop manual (00-4224) still says one dot and is copyrighted 1975.I'm not aware of the dot system applying to any particular British bearing manufacturer.

As with most things this one dot/C2 bearing has been discussed before, several times.

Clutch basket play and ? gearbox problems on MK3.

Yesterday I fitted a new clutch centre and bearing to my clutch on my Commando MK3, as the gearbox was difficult to select gears and it was not possible to select neutral whilst the engine was running. I also have a cross shaft and cross shaft bush on order to be fitted next week. I fitted...www.accessnorton.com

Clutch wobble

Here’s a wee Mpeg I took of the Commando today after putting things back together (again) The quality ain’t brilliant and it looks like a kinda strobe effect slowing things down but you can clearly see the wobble of the clutch basket. http://s14.photobucket.com/albums/a340/ ...www.accessnorton.com

How Much Wobble?

I am re-manufacturing a 1975 Mk III roadster, I am now doing logistics for the primary drive. The first item I have replaced is the bearing between the clutch basket and the clutch center. I purchased a Chinese made bearing, put it in using thermal methods (no hammering on the bearing). I let it...www.accessnorton.com

Clutch basket wobble

My clutch basket is not very solid with respect to the gearbox output shaft - wobbles. The clutch center on the other hand is nice and solid. The only thing keeping the basket in place is the bearing and that's fairly new. I expect this is normal, but has anyone found a way to resolve this -...www.accessnorton.com

Andover, as far as I'm aware supplies the standard 6007 bearing even though they should know it's a C2.

Clutch bearing/clutch centre fit?

Where is the information that specs the 060750 as a C2 or 'one dot'? Go back one page.www.accessnorton.com

Yes, like many things, it has been discussed before - but re-read them all like I just did - they don't say much.

After a lot of searching, I finally found one page that says the internal clearance of C3 is .004" - .010" larger than C2. (conflicts greatly with what I say next).

SKF says this for a 6007 sized bearing (microns):

Steel C2 1-11 CN 6-23 C3 15-36

Stainless Steel C2 3-8 CN 5-10 C3 8-13

So a modern stainless steel C3 is in the range of a plain steel C2 at least for SKF.

I also haven't found any evidence that one dot of yesteryear is the same as C2 today especially since the materials and manufacturing tolerances are different today - Joe's complete post that you linked also says that.

I did find a FAG document that says the deep-groove bearings are only made in CN unless special arrangements are made.

It's appears to me that C2/CN/C3 are not standards but are just what everyone says - C2 has less clearance than CN and C3 has more clearance than CN.

You will also find that C2 = "Low Speed Operation" and C3 = "High Speed Operation", whatever that means.

The question has been asked many times in the past, what is the difference. 'One dot' these markings can be seen on old bearings, confusing as on some it is a dot '.' and some it is a hard to see lightly etched round 'O' This is not the whole story, bearing clearance specifications back in the 70's were not actually formalised it seems, and even today the clearance standard is still not consistent, I believe Japanese manufacturers use their own. Bearing standards that are seen usually relate to the fitting of the shaft and housing clearances in which they fit, great, but the clearance specifications can still overlap, so the bottom end of the normal clearance can also be in the loose end of the C2 clearance of a different manufacturer. That is why most bearing manufacturers insist that customers look at the data they provide for their bearings for the specific purpose, one manufacturer could differ from another.

Clutch bearings, the drawing was originally 'one dot' but then amended to C2. I like Greg have found no way to see how these compare, even our well renowned globally recognised supplier of bearings can't compare the old with the new. However, in recent days something has come to light which is seen in some of the posts above 'where do you get a C2 bearing from' considering we tried the bearing suppliers we deal with and the manufacturers of Japanese made bearings. This has indicated that there are some C2 bearings which are old stock still about, but how much!! None of the manufacturers or suppliers could provide a regular source of new C2 bearings from stock. So, if you have a C2 bearing fitted the chances are that if you paid through the nose for it then it could be a decent NOS bearing, if not then best of luck. The good news is there seems to no one jumping up and supplying knock offs (at the moment)

So what bearing to fit? back in the 70's in times of loose manufacturing tolerances a C2 most probably covered all bases in that it would fit and last. the standard bearings have been around for ages and numerous have been fitted, and the miles that have put on these suggest there is actually no issues whatsoever in using a bearing with normal clearance. The actual use the clutch bearing will see is most probably minimal compared to its service life cycle, these days they are well tested. So what if you have an original bearing and it is in good condition, simple, clean it and use it, it has most probably got more life left in it than some of us owners.

Clutch bearings, the drawing was originally 'one dot' but then amended to C2. I like Greg have found no way to see how these compare, even our well renowned globally recognised supplier of bearings can't compare the old with the new. However, in recent days something has come to light which is seen in some of the posts above 'where do you get a C2 bearing from' considering we tried the bearing suppliers we deal with and the manufacturers of Japanese made bearings. This has indicated that there are some C2 bearings which are old stock still about, but how much!! None of the manufacturers or suppliers could provide a regular source of new C2 bearings from stock. So, if you have a C2 bearing fitted the chances are that if you paid through the nose for it then it could be a decent NOS bearing, if not then best of luck. The good news is there seems to no one jumping up and supplying knock offs (at the moment)

So what bearing to fit? back in the 70's in times of loose manufacturing tolerances a C2 most probably covered all bases in that it would fit and last. the standard bearings have been around for ages and numerous have been fitted, and the miles that have put on these suggest there is actually no issues whatsoever in using a bearing with normal clearance. The actual use the clutch bearing will see is most probably minimal compared to its service life cycle, these days they are well tested. So what if you have an original bearing and it is in good condition, simple, clean it and use it, it has most probably got more life left in it than some of us owners.

- Joined

- Jan 23, 2021

- Messages

- 18

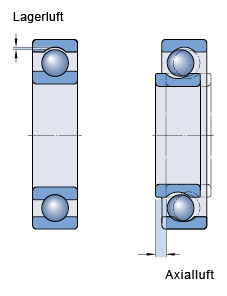

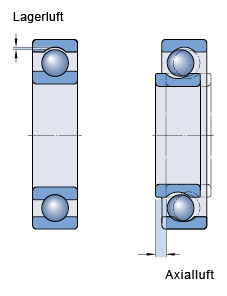

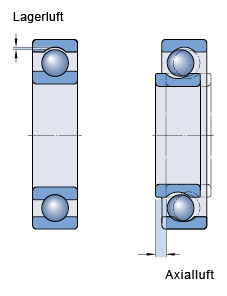

Bearing clearance

The bearing clearance is defined as the total distance by which a bearing ring can be displaced relative to another bearing ring in the radial direction (radial clearance) or in the axial direction (axial clearance).

In almost all applications, the initial clearance in a bearing is greater than the operating clearance. The difference is mainly due to two factors:

The bearings are usually mounted with a tight fit on the shaft or in the housing. By expanding the inner ring or compressing the outer ring, the bearing clearance is reduced.

Bearings in operation generate heat. Differences in the thermal expansion of the bearing and the connecting parts affect the bearing clearance.

During operation, it is important that the bearing has sufficient clearance.

In order to enable selection of the appropriate initial clearance and thereby obtain the desired operating clearance, bearings are available in different clearance classes. According to ISO, five clearance classes are available for numerous types of bearings. The SKF bearing suffixes inform you if the bearing clearance deviates from normal.

ISO internal clearance class

SKF suffix

bearing clearance

-

C1

Bearing clearance smaller than C2

Group 2

C2

Bearing clearance smaller than normal

Groups

-

Normal

Group 3

C3

Bearing clearance greater than normal

Group 4

C4

Bearing clearance greater than C3

Group 5

C5

Bearing clearance greater than C4

The operating clearance required for the bearing to perform its tasks well depends on the specific application (importance of choosing the correct clearance/preload).

It must be ensured that the minimum initial clearance in the event of a reduction due to installation or other influences is at least as large as the required minimum operating clearance.

To do this, proceed as follows:

Determination of the fit-related reduction in bearing clearance

Determination of the reduction in bearing clearance caused by temperature differences

Determination of other effects on the reduction in bearing clearance

Calculation of the required minimum initial bearing clearance.

Selection of the initial clearance range (selection of a clearance class and installation and positioning of bearings).

The term bearing clearance refers to the radial value of the bearing clearance. The absolute value of the bearing clearance CN / C2 / C3 ... also depends on the size of the bearing.

As the size of the bearing increases, the value associated with the tolerance class also increases for the respective class.

There is also a rule of thumb, for example:

Deep groove ball bearings indicate that the axial clearance is approximately 10 times the radial clearance.

The bearing clearance is defined as the total distance by which a bearing ring can be displaced relative to another bearing ring in the radial direction (radial clearance) or in the axial direction (axial clearance).

In almost all applications, the initial clearance in a bearing is greater than the operating clearance. The difference is mainly due to two factors:

The bearings are usually mounted with a tight fit on the shaft or in the housing. By expanding the inner ring or compressing the outer ring, the bearing clearance is reduced.

Bearings in operation generate heat. Differences in the thermal expansion of the bearing and the connecting parts affect the bearing clearance.

During operation, it is important that the bearing has sufficient clearance.

In order to enable selection of the appropriate initial clearance and thereby obtain the desired operating clearance, bearings are available in different clearance classes. According to ISO, five clearance classes are available for numerous types of bearings. The SKF bearing suffixes inform you if the bearing clearance deviates from normal.

ISO internal clearance class

SKF suffix

bearing clearance

-

C1

Bearing clearance smaller than C2

Group 2

C2

Bearing clearance smaller than normal

Groups

-

Normal

Group 3

C3

Bearing clearance greater than normal

Group 4

C4

Bearing clearance greater than C3

Group 5

C5

Bearing clearance greater than C4

The operating clearance required for the bearing to perform its tasks well depends on the specific application (importance of choosing the correct clearance/preload).

It must be ensured that the minimum initial clearance in the event of a reduction due to installation or other influences is at least as large as the required minimum operating clearance.

To do this, proceed as follows:

Determination of the fit-related reduction in bearing clearance

Determination of the reduction in bearing clearance caused by temperature differences

Determination of other effects on the reduction in bearing clearance

Calculation of the required minimum initial bearing clearance.

Selection of the initial clearance range (selection of a clearance class and installation and positioning of bearings).

The term bearing clearance refers to the radial value of the bearing clearance. The absolute value of the bearing clearance CN / C2 / C3 ... also depends on the size of the bearing.

As the size of the bearing increases, the value associated with the tolerance class also increases for the respective class.

There is also a rule of thumb, for example:

Deep groove ball bearings indicate that the axial clearance is approximately 10 times the radial clearance.

marshg246

VIP MEMBER

- Joined

- Jul 12, 2015

- Messages

- 5,121

All regurgitated before here and all over the Internet. Do you agree that there is no ISO or other standard for the clearances other than C2 < CN and C3 > CN?Bearing clearance

The bearing clearance is defined as the total distance by which a bearing ring can be displaced relative to another bearing ring in the radial direction (radial clearance) or in the axial direction (axial clearance).

In almost all applications, the initial clearance in a bearing is greater than the operating clearance. The difference is mainly due to two factors:

The bearings are usually mounted with a tight fit on the shaft or in the housing. By expanding the inner ring or compressing the outer ring, the bearing clearance is reduced.

Bearings in operation generate heat. Differences in the thermal expansion of the bearing and the connecting parts affect the bearing clearance.

During operation, it is important that the bearing has sufficient clearance.

In order to enable selection of the appropriate initial clearance and thereby obtain the desired operating clearance, bearings are available in different clearance classes. According to ISO, five clearance classes are available for numerous types of bearings. The SKF bearing suffixes inform you if the bearing clearance deviates from normal.

ISO internal clearance class

SKF suffix

bearing clearance

-

C1

Bearing clearance smaller than C2

Group 2

C2

Bearing clearance smaller than normal

Groups

-

Normal

Group 3

C3

Bearing clearance greater than normal

Group 4

C4

Bearing clearance greater than C3

Group 5

C5

Bearing clearance greater than C4

The operating clearance required for the bearing to perform its tasks well depends on the specific application (importance of choosing the correct clearance/preload).

It must be ensured that the minimum initial clearance in the event of a reduction due to installation or other influences is at least as large as the required minimum operating clearance.

To do this, proceed as follows:

Determination of the fit-related reduction in bearing clearance

Determination of the reduction in bearing clearance caused by temperature differences

Determination of other effects on the reduction in bearing clearance

Calculation of the required minimum initial bearing clearance.

Selection of the initial clearance range (selection of a clearance class and installation and positioning of bearings).

The term bearing clearance refers to the radial value of the bearing clearance. The absolute value of the bearing clearance CN / C2 / C3 ... also depends on the size of the bearing.

As the size of the bearing increases, the value associated with the tolerance class also increases for the respective class.

There is also a rule of thumb, for example:

Deep groove ball bearings indicate that the axial clearance is approximately 10 times the radial clearance.

- Joined

- May 7, 2005

- Messages

- 7,256

Before the advent of ISO standards for rolling element bearings manufacturers were free to use whatever dimensions, tolerances and markings they saw fit. RHP was the main UK supplier and they used Dots for internal clearance identification stamped near the bearing number, all covered in their Engineering Design Manual. Other bearing makers used O's etched onto the bearing in a visible location plus other variations. When the ISO standards came out then the C classification started.

marshg246

VIP MEMBER

- Joined

- Jul 12, 2015

- Messages

- 5,121

Do you have that RHP manual? Can you state the clearances of the various dots? Do you know of an ISO standard that specifies the actual clearances for C2/CN/C3 or the math to determine them?Before the advent of ISO standards for rolling element bearings manufacturers were free to use whatever dimensions, tolerances and markings they saw fit. RHP was the main UK supplier and they used Dots for internal clearance identification stamped near the bearing number, all covered in their Engineering Design Manual. Other bearing makers used O's etched onto the bearing in a visible location plus other variations. When the ISO standards came out then the C classification started.

Similar threads

- Replies

- 3

- Views

- 207

- Replies

- 25

- Views

- 1,394

- Replies

- 12

- Views

- 1,080