Sorry, I got interrupted by the enemy declaring a state of teatime.

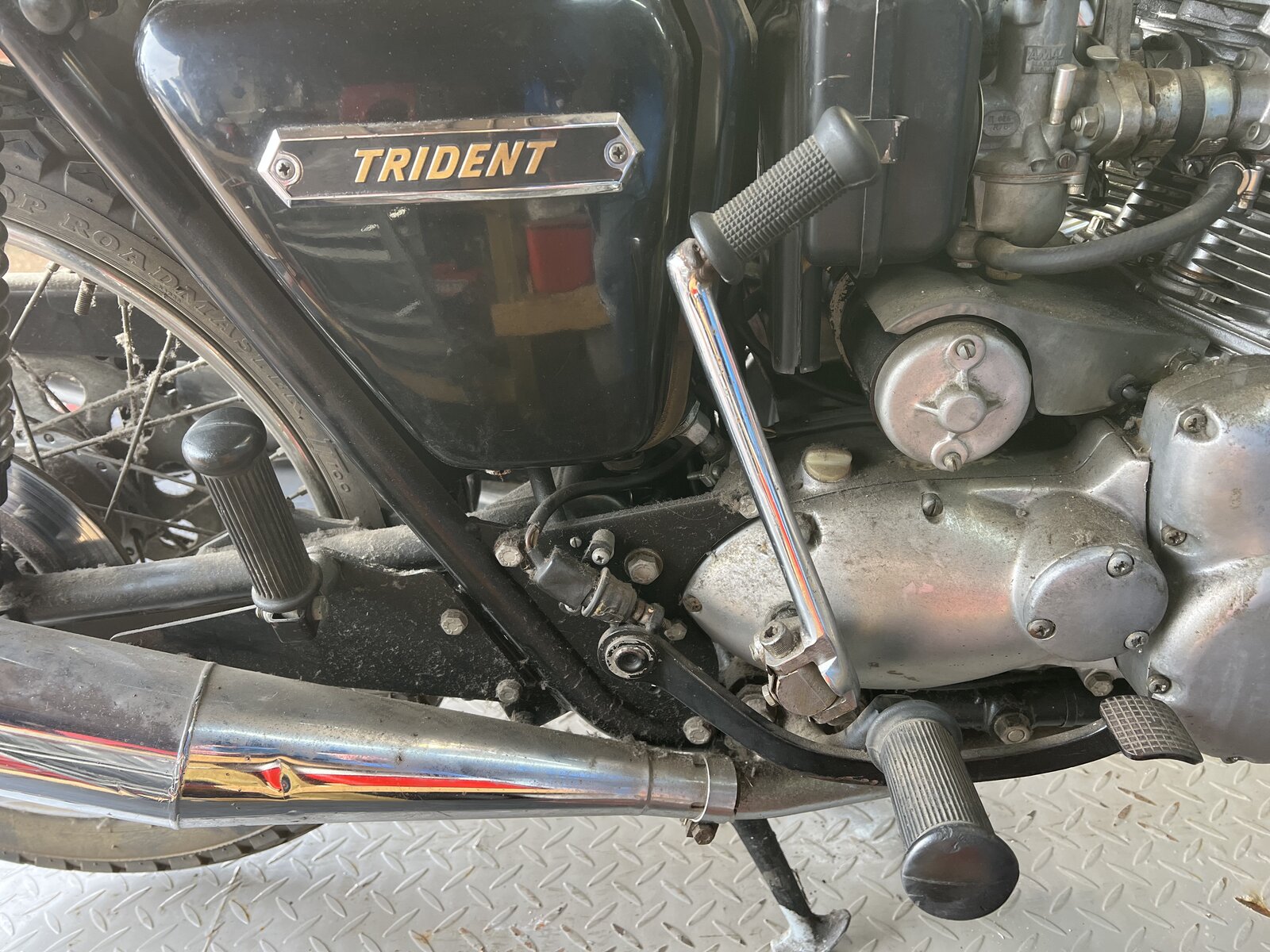

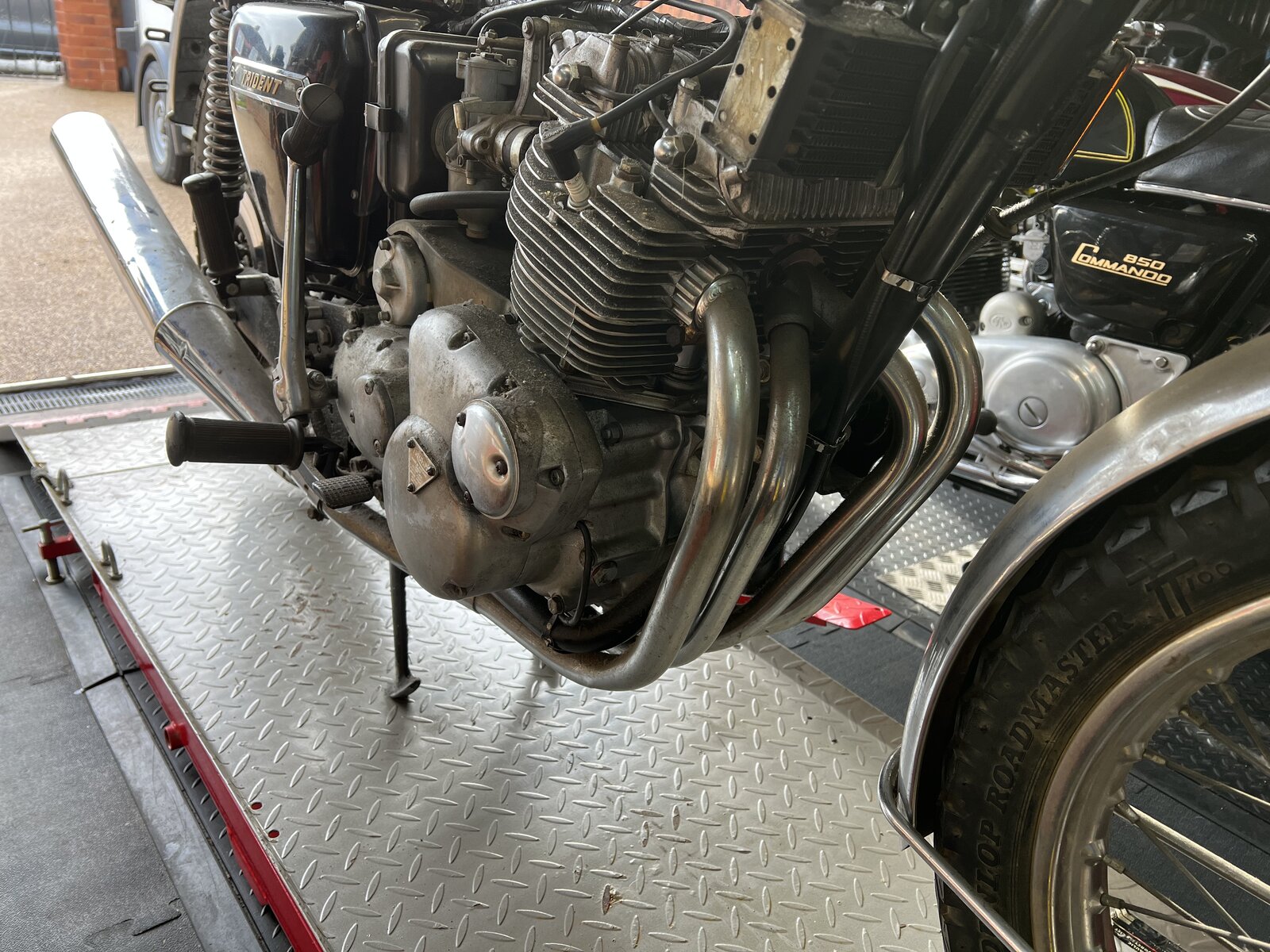

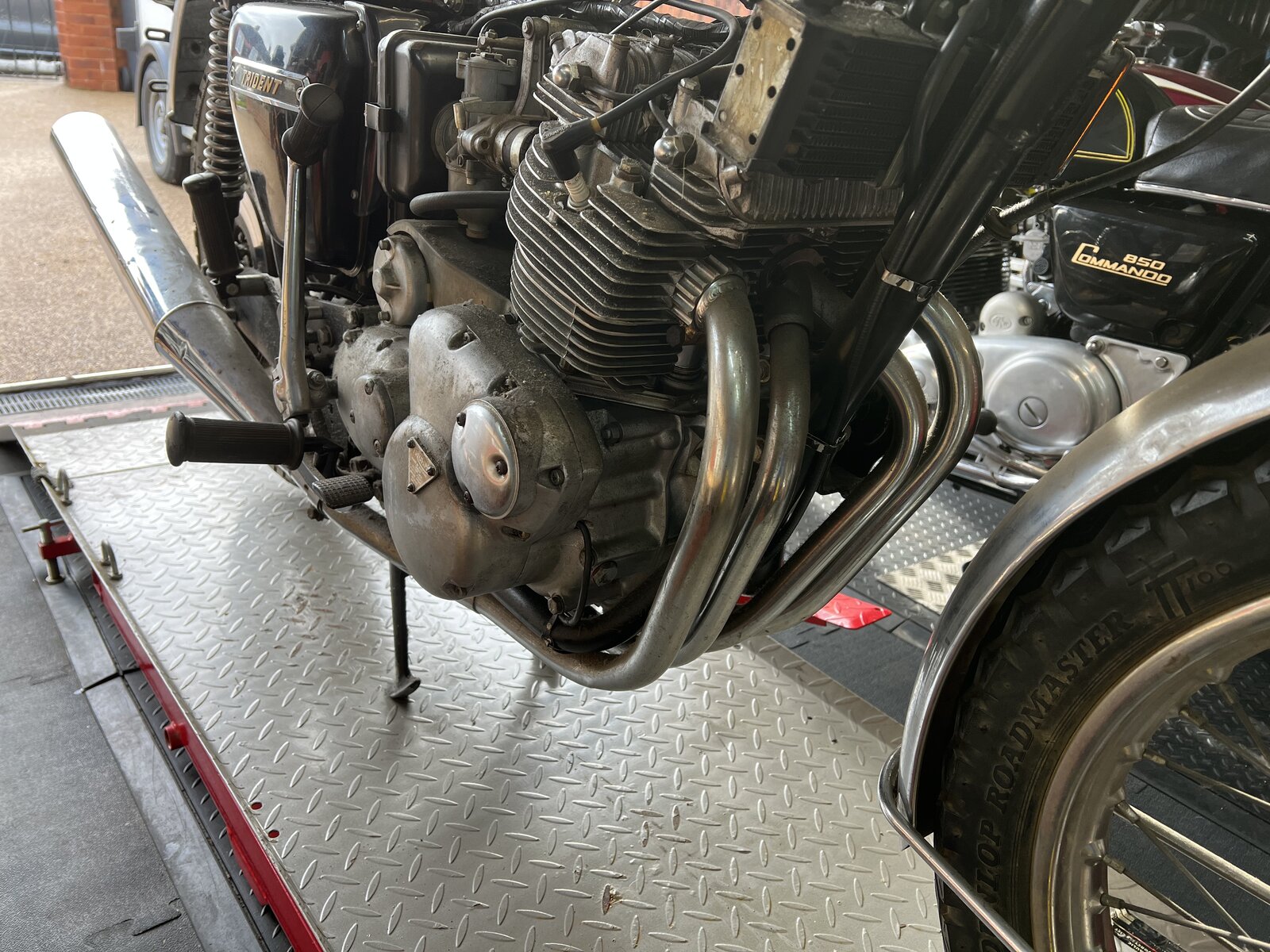

under mounds of dust it’s quite nice. Sadly, being housed in a working warehouse environment it hasn’t fared well. Dings here, dents there, scratches despite being under a bike cover. However all of the nuts, screws, bolts and other fasteners have come apart easily so far.

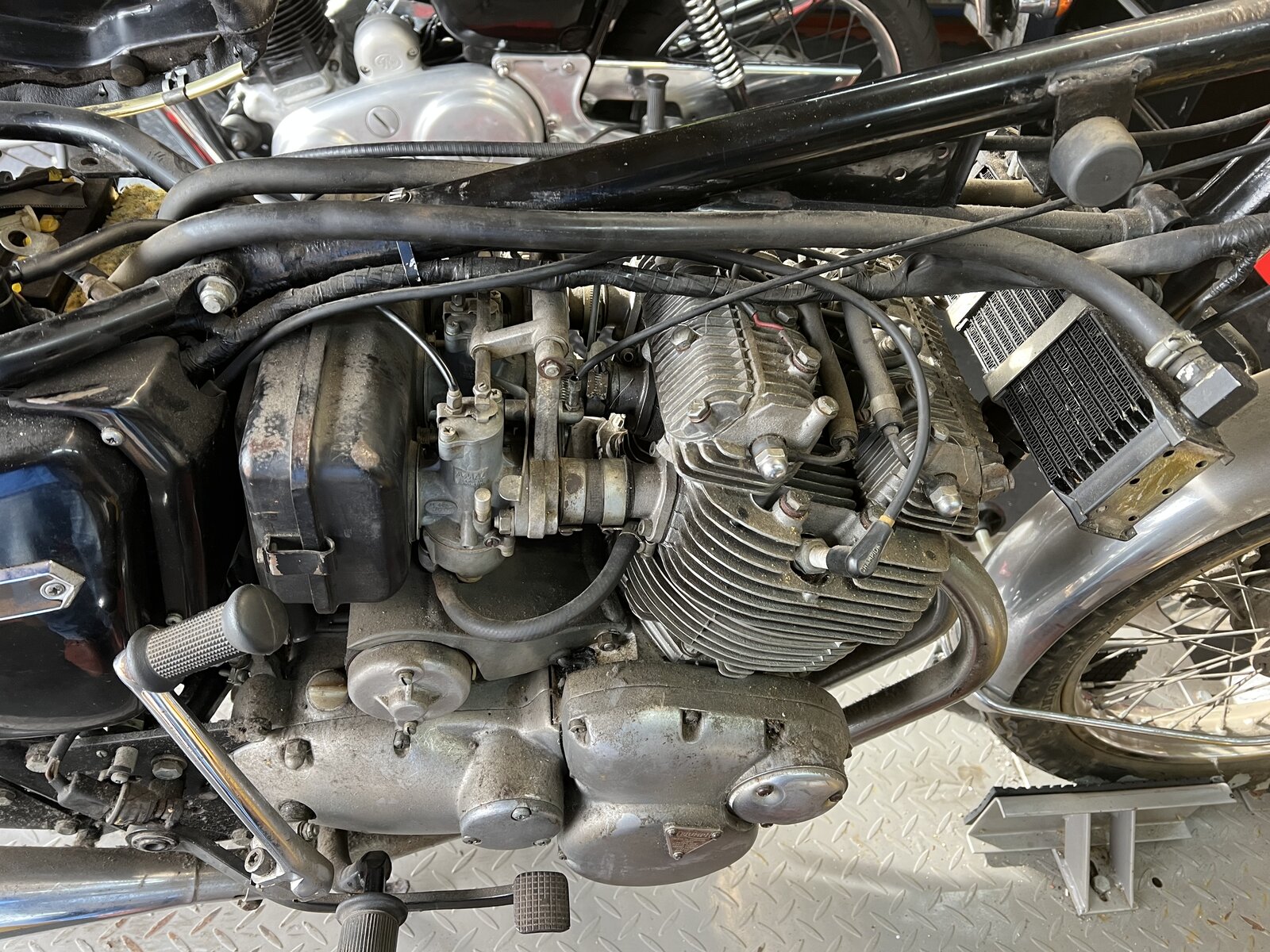

I’ve removed the bars, the master cylinder (full of dried fluid, it’s scrap) and the switchgear, along with the headlamp. Bugger! The rh side headlamp hanger is badly dented but may knock out, maybe, if not I’ll get a pair of stainless ones made up.

The caliper is next to come off, the pads are scrap and have gone powdery. But of course to get that off, the wheel needs to come out. That’ll do for today. Time to rest up.

Tomorrow perhaps a dip in the ultrasonic tank for the switchgear. And on the subject of switchgear - see the difference stock screw against the solitary self tapper in the left switch. If the thread is buggered I have a faulty T140 switch I can rob the carcass off m