- Joined

- Nov 26, 2009

- Messages

- 3,411

Seattle - yes I tested this and many other things on my monoshock when I was racing.. See vid at:

MarshG246 - there is enough play in the engine cradle bolts etc to align the head steady.

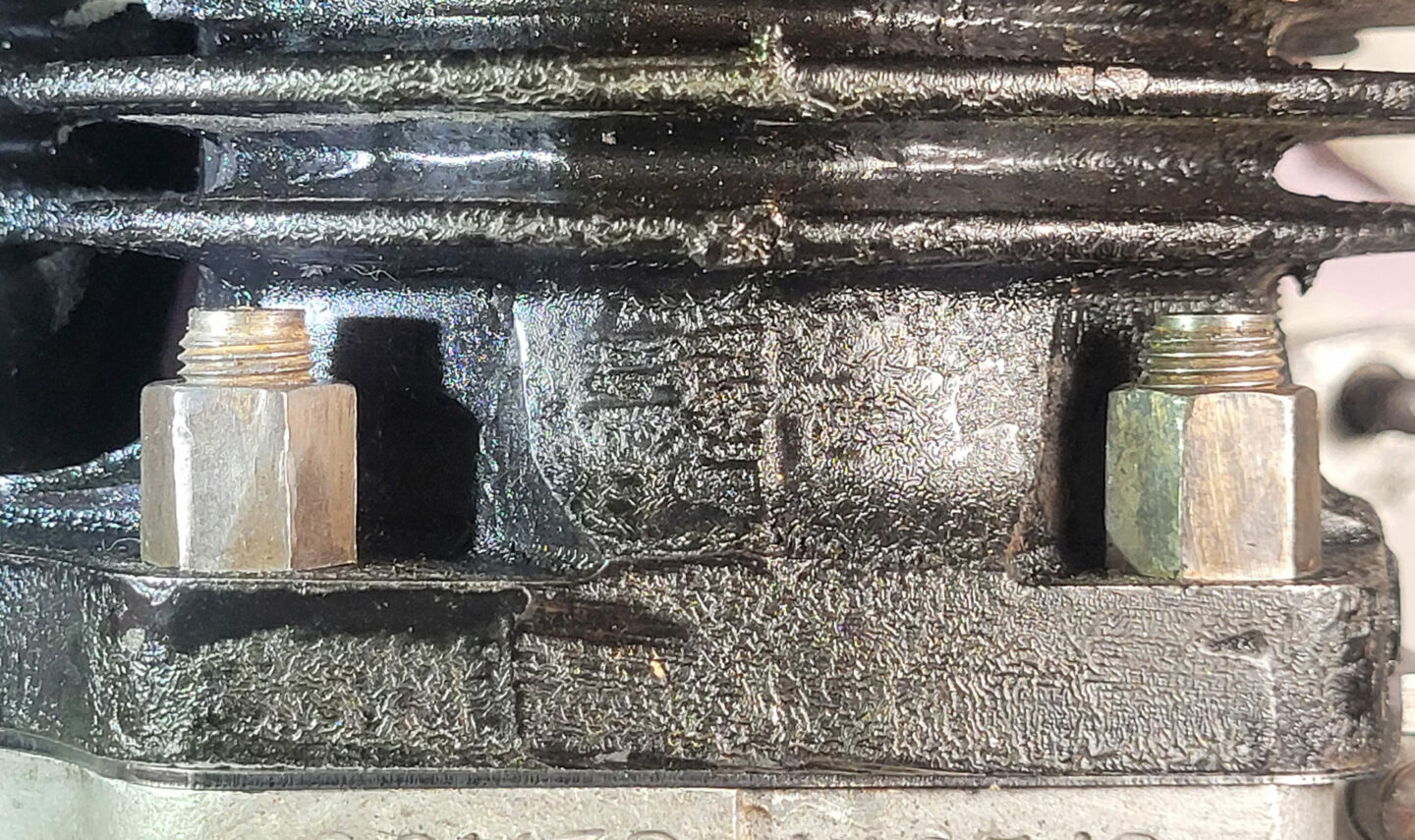

mtd-son - In real life there is no gap on one side of the nut. I tried it and could not even get a .0015" feeler gauge to slip under the nut because there is some free play in the threads - try it yourself and you'll see. You don't need to modify the nuts and washers - I've already tested it.

I'm not saying you should tear your motor down for this. But its an easy thing to do on the next rebuild.

MarshG246 - there is enough play in the engine cradle bolts etc to align the head steady.

mtd-son - In real life there is no gap on one side of the nut. I tried it and could not even get a .0015" feeler gauge to slip under the nut because there is some free play in the threads - try it yourself and you'll see. You don't need to modify the nuts and washers - I've already tested it.

I'm not saying you should tear your motor down for this. But its an easy thing to do on the next rebuild.