Thanks for visiting Access Norton

- Guest view limit reached

- Create a free account (more details)

- Already a member? Click here to login

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Best fork bushings?

- Thread starter concours

- Start date

- Status

- Not open for further replies.

laurentdom

VIP MEMBER

- Joined

- Nov 30, 2012

- Messages

- 257

To me, Jim Schmidt (at jsmotorsport) turcite ones.

Mark Savage

VIP MEMBER

- Joined

- Apr 2, 2013

- Messages

- 857

- Joined

- Dec 28, 2008

- Messages

- 2,035

New York city Norton.

I installed a set of OE bushings on new sanctions after two sets of the OE bronze/metal had too much sticktion no matter where the tubes where rotated. After installing the seal/bushing kit from NYC Norton the sliders in lower clamp with axle throw the sliders moved like a trombone.

Best.

I installed a set of OE bushings on new sanctions after two sets of the OE bronze/metal had too much sticktion no matter where the tubes where rotated. After installing the seal/bushing kit from NYC Norton the sliders in lower clamp with axle throw the sliders moved like a trombone.

Best.

Synthetic fork bushings (2019)

I started using teflon lined fork bushings in Norton forks back in the 1980s (Suzuki part #51121-49510) as described in the JS race manual. They were slippery but the Teflon coating is soft, they would wear down to the underlying bronze and then you were back to metal to metal friction. When...

- Joined

- Aug 12, 2011

- Messages

- 1,431

Concours,Thank you everyone.

I installed the Cosentino ones from NYC Norton and am very pleased with the fit and operation.

Mike

robs ss

VIP MEMBER

- Joined

- Aug 16, 2016

- Messages

- 4,336

Does anyone have knowledge of how the Turcite bushes compare with the NYC Norton (Consentino) bushes in operation?

I have Landsdowne units ready for installation on my 650 together with a set of Turcite bushes but am interested in this comparison - if anyone knows.

Cheers

I have Landsdowne units ready for installation on my 650 together with a set of Turcite bushes but am interested in this comparison - if anyone knows.

Cheers

- Joined

- May 7, 2005

- Messages

- 7,711

Both are low friction plastics but the Turcite is full thickness of bush vs the Consentino is steel backed PTFE, so the Cosentino will give similar low friction but not deform as much as the Turcite under load. The Consentino is also based on modern standard fork bush practice so well understood.Does anyone have knowledge of how the Turcite bushes compare with the NYC Norton (Consentino) bushes in operation?

- Joined

- Nov 26, 2009

- Messages

- 3,411

Kommando - the Turcite holds its shape perfectly and does not deform or wear away like softer Teflon.

I was the first to use teflon lined metal bushings in Norton forks way back in the 80s. Over time Teflon can wear down to the underlying metal - this is what happened on my race bike and that's why I went to Turcite. Sure Teflon works good - it just doesn't last as long as Turcite.

History:

I was sponsoring Kenny Cummings when I first came out with the slippery turcite bushings. Kenny had Cosentino copy them without asking me. But Cosentino missed something important when he machined them and they didn't work out. Kenny read my race manual with the Teflon lower bushing info as shown in the illustration below. Later he came out with the Teflon bushings without telling me.

I can change to Teflon at any time but I choose to go with the more reliable Turcite bushings even though the material is more expensive. Turcite is used on machine tool guideways to bear heavy sliding loads and reduce wear and friction. Teflon would not hold up in those conditions. Another problem with the Teflon bushings is that you have a coated bushing and also a steel sleeve to hold the bushing, Both components must have clearance to fit the forks so you end up with more slop - especially when the teflon starts to wear. Note the shim stock mentioned in the illustration. The fork companies use Teflon because its cheaper. I don't think Turcite was available back then when they first came out with sythetic bushings. Should I change to Teflon? So far I'm happy with Turcite's tight tolerance and superior longevity.

The Teflon lined bushing I first started using in the 80s. The part # is different but its basically the same.

The original prototype Turcite bushings were made on my manual lathe many years ago and they are still in use today.

You can copy another product or someone else's idea. But the best thing to do is come out with something new that out preforms the competition -that's what racing is all about and racing is what produces most of the performance improvements.

I was the first to use teflon lined metal bushings in Norton forks way back in the 80s. Over time Teflon can wear down to the underlying metal - this is what happened on my race bike and that's why I went to Turcite. Sure Teflon works good - it just doesn't last as long as Turcite.

History:

I was sponsoring Kenny Cummings when I first came out with the slippery turcite bushings. Kenny had Cosentino copy them without asking me. But Cosentino missed something important when he machined them and they didn't work out. Kenny read my race manual with the Teflon lower bushing info as shown in the illustration below. Later he came out with the Teflon bushings without telling me.

I can change to Teflon at any time but I choose to go with the more reliable Turcite bushings even though the material is more expensive. Turcite is used on machine tool guideways to bear heavy sliding loads and reduce wear and friction. Teflon would not hold up in those conditions. Another problem with the Teflon bushings is that you have a coated bushing and also a steel sleeve to hold the bushing, Both components must have clearance to fit the forks so you end up with more slop - especially when the teflon starts to wear. Note the shim stock mentioned in the illustration. The fork companies use Teflon because its cheaper. I don't think Turcite was available back then when they first came out with sythetic bushings. Should I change to Teflon? So far I'm happy with Turcite's tight tolerance and superior longevity.

The Teflon lined bushing I first started using in the 80s. The part # is different but its basically the same.

The original prototype Turcite bushings were made on my manual lathe many years ago and they are still in use today.

You can copy another product or someone else's idea. But the best thing to do is come out with something new that out preforms the competition -that's what racing is all about and racing is what produces most of the performance improvements.

Last edited:

concours

VIP MEMBER

- Joined

- Dec 29, 2011

- Messages

- 10,359

I have the turcite. They are of the "split" variety, and, as such tighten up like a collet on a tool.Does anyone have knowledge of how the Turcite bushes compare with the NYC Norton (Consentino) bushes in operation?

I have Landsdowne units ready for installation on my 650 together with a set of Turcite bushes but am interested in this comparison - if anyone knows.

Cheers

In my box of "stuff that didn't work".

JMWO

- Joined

- Nov 11, 2013

- Messages

- 5,411

I had to fettle mine with a bit of wet dry as only one of them did that. Fixed it right up and smoothly sliding.I have the turcite. They are of the "split" variety, and, as such tighten up like a collet on a tool.

In my box of "stuff that didn't work".

JMWO

- Joined

- May 7, 2005

- Messages

- 7,711

Kommando - the Turcite holds its shape perfectly and does not deform or wear away like softer Teflon.

You do realise that Turcite is a PTFE based material, the majority of its content is PTFE and the difference compared to first PTFE based bush is the filler. On Turcite the filler will be likely glass fibre or similar, the first PTFE bushes used lead.I can change to Teflon at any time but I choose to go with the more reliable Turcite

What is Turcite® (Lubring)?

Quite simply – Turcite® is PTFE impregnated with fillers

Turcite - Material Characteristics And Applications | Bearings from Poly Fluoro Ltd

Turcite® is PTFE impregnated with fillers and additives that serve to enhance the wear properties of the material. It is used, most often in a sheet form, in thicknesses ranging from 0.5mm (0.02”) to 4mm (0.16”), although in some applications, it is also used as a bush and in more rare...

The same material but branded differently is available from Glacier but with a steel backing, as NYC do not say what filler they use then they could also be using a filler of the same type as Turcite.

Other PTFE type materials are available from other sources, all variations on a common theme, base material is PTFE.

And on the deformation, until someone develops a PTFE material with the physical properties of steel then a steel backed bush will always deform less that a PTFE only bush of same thickness.

Last edited:

robs ss

VIP MEMBER

- Joined

- Aug 16, 2016

- Messages

- 4,336

When you say "fettle" - did you work on the OD?I had to fettle mine with a bit of wet dry as only one of them did that. Fixed it right up and smoothly sliding.

Considering a wall thickness of 2mm or less, and the fact that pressure is spread across a surface comprised of height times a 180 degree circumference (where pressure varies from nil to max to nil), I don't think deformation of bushes is an issue in this application.And on the deformation, until someone develops a PTFE material with the physical properties of steel then a steel backed bush will always deform less that a PTFE only bush of same thickness.

- Knut

- Joined

- Nov 26, 2009

- Messages

- 3,411

mtd-son said "I don't think deformation of bushes is an issue in this application." That is correct.

Concours - The instructions say:

"Your fork tubes should measure between 1.356” and 1.359” (original Norton tube specs)."

You sent me a PM a couple years ago saying that your forks measured 1.3594”. I suggested that you return them so I could fit them to your oversize tubes but you never sent them. Please take me up on my offer. You've got an exellent set of bushings there - if you would just let me re-size them for your oversize tubes.

EVERY SET of Turcite bushings is mocked up in a slider and FACTORY SIZE fork tube to verify the fit before shipping. Forks by Frank can be oversize. There have been a couple customers with oversize tubes. I just edited my website so you have the choice of bushings to fit standard factory 1.356-1.359" tubes or bushings to fit 1.359+" oversize aftermarket tubes to solve this rare problem.

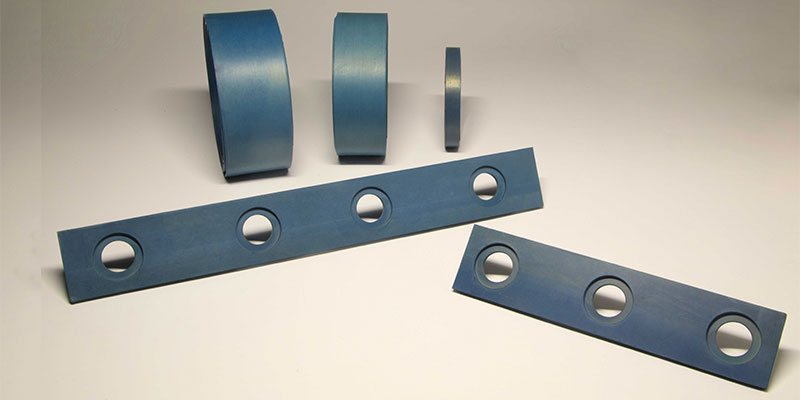

See the very first prototype Turcite fork bushings below. After many thousands of miles there is no measurable wear or distortion.

Concours - The instructions say:

"Your fork tubes should measure between 1.356” and 1.359” (original Norton tube specs)."

You sent me a PM a couple years ago saying that your forks measured 1.3594”. I suggested that you return them so I could fit them to your oversize tubes but you never sent them. Please take me up on my offer. You've got an exellent set of bushings there - if you would just let me re-size them for your oversize tubes.

EVERY SET of Turcite bushings is mocked up in a slider and FACTORY SIZE fork tube to verify the fit before shipping. Forks by Frank can be oversize. There have been a couple customers with oversize tubes. I just edited my website so you have the choice of bushings to fit standard factory 1.356-1.359" tubes or bushings to fit 1.359+" oversize aftermarket tubes to solve this rare problem.

See the very first prototype Turcite fork bushings below. After many thousands of miles there is no measurable wear or distortion.

Last edited:

- Joined

- Nov 26, 2009

- Messages

- 3,411

mtd-son said "I don't think deformation of bushes is an issue in this application." That is correct.

Concours - The instructions say:

"Your fork tubes should measure between 1.356” and 1.359” (original Norton tube specs)."

You sent me a PM a couple years ago saying that your forks measured 1.3594”. I suggested that you return them so I could fit them to your oversize tubes but you never sent them. Please take me up on my offer. You've got an exellent set of bushings there - if you would just let me re-size them for your oversize tubes.

EVERY SET of Turcite bushings is mocked up in a slider and FACTORY SIZE fork leg to verify the fit before shipping. Forks by Frank can be oversize. There have been a couple customers with oversize tubes. I just edited my products page - now you can choose bushings for standard factory 1.356-1.359" tubes or bushings for 1.359+" aftermarket tubes to solve this rare problem.

See the original prototype bushings below. These are the very first Turcite fork bushings and there is no measurable wear or distortion.

Last edited:

concours

VIP MEMBER

- Joined

- Dec 29, 2011

- Messages

- 10,359

Jim, That was an offer I considered and decided to not pursue. My time is valuable, therefore the back and forth and tear downs have value. That is, time taken away from riding, and time from my family. I know many here find that tinkering enjoyable, and to some as much of the vintage bike satisfaction experience as any other part of it. As a (not retired yet) professional mechanic, the time repairing, I know must be put in to enjoy the ride. The REWORK however, holds a special place for me. I work repairing box way milling & turning centers, and agreed this was a material of interest. When these turned out to bind, and you explained you had chosen to slit the length of them to adapt to many tube size variations, I tapped out. That was a VERY POOR idea to solve the problem. Had you mentioned, in advance, you'd need the O.D. of the tubes and I.D of the fork leg measured and dimensions supplied, to custom make the bushings (with NO SLIT) I'd have respected that. Instead, I got taken for a fork teardown ride. How come the image above doesn't show the slit?mtd-son said "I don't think deformation of bushes is an issue in this application." That is correct.

Concours - The instructions say:

"Your fork tubes should measure between 1.356” and 1.359” (original Norton tube specs)."

You sent me a PM a couple years ago saying that your forks measured 1.3594”. I suggested that you return them so I could fit them to your oversize tubes but you never sent them. Please take me up on my offer. You've got an exellent set of bushings there - if you would just let me re-size them for your oversize tubes.

EVERY SET of Turcite bushings is mocked up in a slider and FACTORY SIZE fork tube to verify the fit before shipping. Forks by Frank can be oversize. There have been a couple customers with oversize tubes. I just edited my website so you have the choice of bushings to fit standard factory 1.356-1.359" tubes or bushings to fit 1.359+" oversize aftermarket tubes to solve this rare problem.

See the very first prototype Turcite fork bushings below. After many thousands of miles there is no measurable wear or distortion.

But hey, that's just me. If most of your customers enjoy tearing the forks down multiple times, have at it. But, I'm out. So putting those bushings in a clean ziplock bag, in the box of misfit parts, was cheaper than continuing on.

Best Regards

Last edited:

- Joined

- Oct 12, 2009

- Messages

- 8

>>Kenny had Cosentino copy them without asking me. But Cosentino missed something important when he machined them and they

>>didn't work out. Kenny read my race manual with the Teflon lower bushing info as shown in the illustration below. Later he came

>>out with the Teflon bushings without telling me.

That's a few nice lines of fiction, jseng1. If you had invented Turcite (which is Teflon with some fillers to give it structural strength) you may have a leg to stand on, but the concept of replacing an older, poorly performing material with a newer, better performing material is the main theme of vintage racing and of engineering in general. Norton forks are an outlier in using metal bushings, so replacing them for better performance is not exactly taking a leap of faith! As an engineer, I have designed Turcite bushings for several client projects. There is nothing secretive or magical about it. But it is expensive and for the shape of the Norton parts you end up throwing most of it away as chips, not a very efficient approach in my book. Also, when every telescopic fork manufacturer in the world chooses a different material to use in their products, from the cheapest commuter design to the most expensive Ohlins roadrace unit, you have to wonder why. The reason is that a Teflon sheet applied to a sintered bronze layer that has been bonded to a steel strip is lower friction than Turcite because 100% of the contact surface is Teflon, where in a Turcite bush, the Teflon is mixed with bronze (the material we are replacing!) among other things, all with higher friction than Teflon, to give it the strength that the metal backing of a DU bushing gives. Yes, the first set I made were Turcite, but only because it is a high performance bushing material, the same reason you chose to use it! After testing them I did not think the performance increase was as much as was possible, so the next choice was a modified DU bush, which did give the reduction in friction that was expected.

That is why I decided that in making the best bushing upgrade kit the DU bush style was the better choice. The reason that I decided to start this product is an experience in the pits at Barber trying to get a softly sprung set of Roadholders sliding smoothly. I was horrified at seeing what the OEM configuration was and how it performed! I did not see any reason to notify you as to my plans. The drawback to this approach is the need to pay for custom tooling to be made for the unusual fork diameter (which I did) and then order a minimum of 500 sets (which I also did). So there is a lot of initial expense, making purchasing Turcite and cutting it up seem like an easier approach, and economically it is, but you end up with an inferior end product.

>>You can copy another product or someone else's idea. But the best thing to do is come out with something new that out preforms the competition -that's what racing is all about and racing is what produces most of the performance improvements.

As I said before, improving the breed is not your idea. Neither is swapping better parts from newer bikes on to older bikes. And my kit does come out with something new and does outperform the competition. The Teflon bushes are lower friction than the OEM and your Turcite versions. The machined aluminum upper carrier enables the use of a modern lip design fork seal, which is lower friction than the OEM setup, which your product does not improve on. OEM seal drag is a significant contributor to the overall friction, hence my desire to improve that area too. My machined carrier design also uses a retaining clip to hold the seal in, not a threaded retainer that can easily distort the seal body, causing even more seal drag. So, low friction, low friction, and easy assembly IMO make for the best product out there.

Here comes the shamless plug: email Kenny for a set today!

Chris Cosentino

Cosentino Engineering

>>didn't work out. Kenny read my race manual with the Teflon lower bushing info as shown in the illustration below. Later he came

>>out with the Teflon bushings without telling me.

That's a few nice lines of fiction, jseng1. If you had invented Turcite (which is Teflon with some fillers to give it structural strength) you may have a leg to stand on, but the concept of replacing an older, poorly performing material with a newer, better performing material is the main theme of vintage racing and of engineering in general. Norton forks are an outlier in using metal bushings, so replacing them for better performance is not exactly taking a leap of faith! As an engineer, I have designed Turcite bushings for several client projects. There is nothing secretive or magical about it. But it is expensive and for the shape of the Norton parts you end up throwing most of it away as chips, not a very efficient approach in my book. Also, when every telescopic fork manufacturer in the world chooses a different material to use in their products, from the cheapest commuter design to the most expensive Ohlins roadrace unit, you have to wonder why. The reason is that a Teflon sheet applied to a sintered bronze layer that has been bonded to a steel strip is lower friction than Turcite because 100% of the contact surface is Teflon, where in a Turcite bush, the Teflon is mixed with bronze (the material we are replacing!) among other things, all with higher friction than Teflon, to give it the strength that the metal backing of a DU bushing gives. Yes, the first set I made were Turcite, but only because it is a high performance bushing material, the same reason you chose to use it! After testing them I did not think the performance increase was as much as was possible, so the next choice was a modified DU bush, which did give the reduction in friction that was expected.

That is why I decided that in making the best bushing upgrade kit the DU bush style was the better choice. The reason that I decided to start this product is an experience in the pits at Barber trying to get a softly sprung set of Roadholders sliding smoothly. I was horrified at seeing what the OEM configuration was and how it performed! I did not see any reason to notify you as to my plans. The drawback to this approach is the need to pay for custom tooling to be made for the unusual fork diameter (which I did) and then order a minimum of 500 sets (which I also did). So there is a lot of initial expense, making purchasing Turcite and cutting it up seem like an easier approach, and economically it is, but you end up with an inferior end product.

>>You can copy another product or someone else's idea. But the best thing to do is come out with something new that out preforms the competition -that's what racing is all about and racing is what produces most of the performance improvements.

As I said before, improving the breed is not your idea. Neither is swapping better parts from newer bikes on to older bikes. And my kit does come out with something new and does outperform the competition. The Teflon bushes are lower friction than the OEM and your Turcite versions. The machined aluminum upper carrier enables the use of a modern lip design fork seal, which is lower friction than the OEM setup, which your product does not improve on. OEM seal drag is a significant contributor to the overall friction, hence my desire to improve that area too. My machined carrier design also uses a retaining clip to hold the seal in, not a threaded retainer that can easily distort the seal body, causing even more seal drag. So, low friction, low friction, and easy assembly IMO make for the best product out there.

Here comes the shamless plug: email Kenny for a set today!

Chris Cosentino

Cosentino Engineering

- Status

- Not open for further replies.

Similar threads

- Replies

- 18

- Views

- 1,734

- Replies

- 7

- Views

- 1,133

- Replies

- 19

- Views

- 6,099