worntorn

VIP MEMBER

- Joined

- Dec 22, 2006

- Messages

- 7,963

My JD 2755 developed a big hydraulic leak yesterday. On inspection one of the steel high pressure lines under the floor board was the culprit.

I had a tough time getting the fittings off as that line has never been removed before now. Rust may have been a factor. With a pipe extension on the spanner and most of my body weight hanging/yanking on the end, the compression nuts let go with a bang.

I was definitely missing the use of those two torn off rotator cuff muscles, but managed without.

The section of line that was leaking was very corroded right where it was clamped to the frame. The clamp provided a great trap for dirt, moisture or things like chicken manure or granular fertilizer, which this machine has spread many times. In future I will pay attention to that area and clean it thoroughly with the pressure washer.

The new part is available from John Deere at $530 Canadian. It would take a week or so to get here.

I decided to try fixing the existing line as other than in the corroded clamp area the line and fittings look like new.

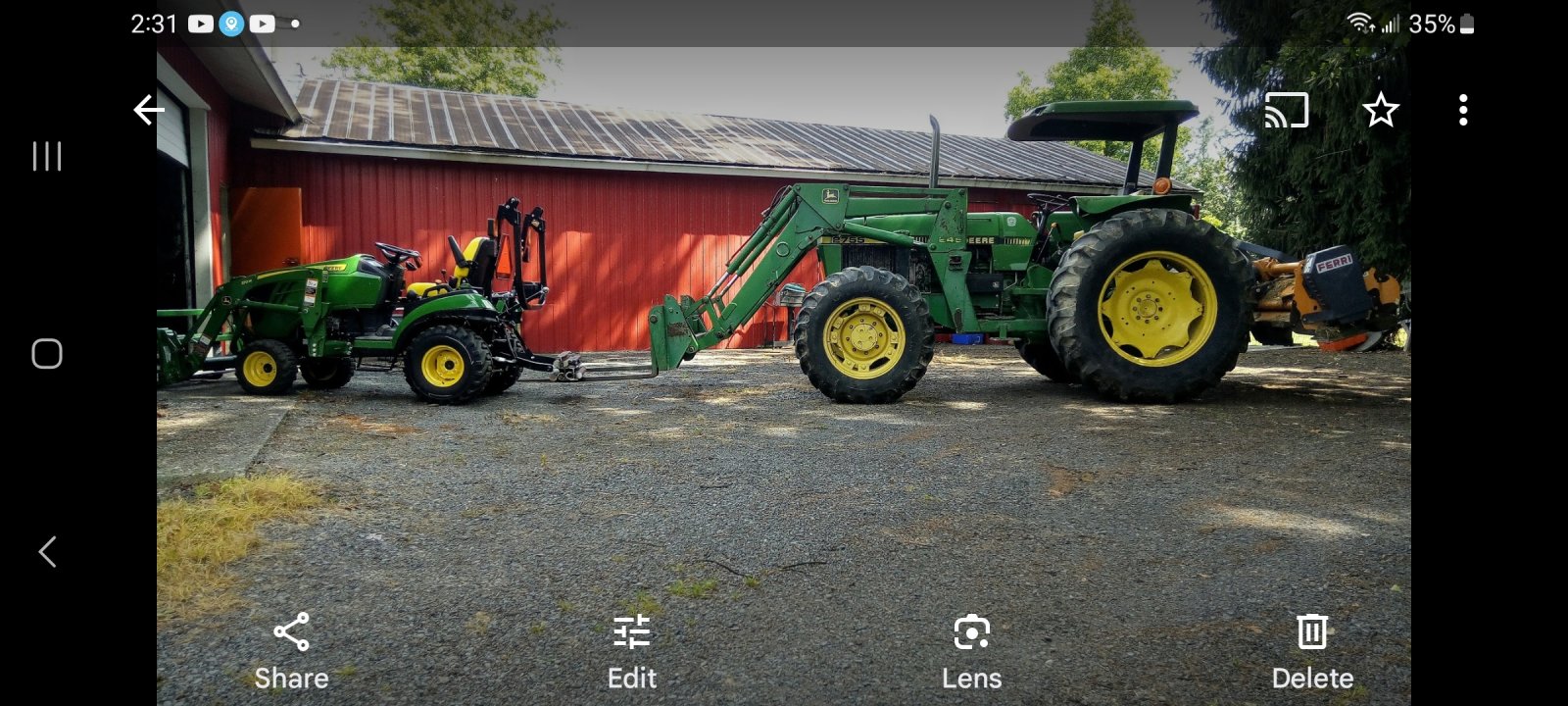

Here is the tractor

It's the larger of the two-

Here is the pressure line in question-

Here is the pressure line in question-

I had a tough time getting the fittings off as that line has never been removed before now. Rust may have been a factor. With a pipe extension on the spanner and most of my body weight hanging/yanking on the end, the compression nuts let go with a bang.

I was definitely missing the use of those two torn off rotator cuff muscles, but managed without.

The section of line that was leaking was very corroded right where it was clamped to the frame. The clamp provided a great trap for dirt, moisture or things like chicken manure or granular fertilizer, which this machine has spread many times. In future I will pay attention to that area and clean it thoroughly with the pressure washer.

The new part is available from John Deere at $530 Canadian. It would take a week or so to get here.

I decided to try fixing the existing line as other than in the corroded clamp area the line and fittings look like new.

Here is the tractor

It's the larger of the two-

Last edited: