o0norton0o

VIP MEMBER

- Joined

- Apr 27, 2015

- Messages

- 1,756

I hate when someone hijacks my thread, so I started a new one about the wristpin circlip question

..... but I didn't say G-forces did I?? If anything I should have said "mass" of the return wire... not weight. Of course it's inertial force and not gravity. Who said it was gravity???

and neither did I say that all wire circlips are no good, just the ones I got with the pistons I bought. (I'll post pictures of the circlips in question and even the damaged circlip that popped out, which I saved)

Right, the circlip you posted combined with the groove shape in the piston and shape of the wrist pin look like an excellent system. I have no doubt that Jim Smith's pistons with wire circlips work excellenty, NOR did I ever imply that they didn't work well. Only that the ones I got with my pistons seemed like crap to ME.

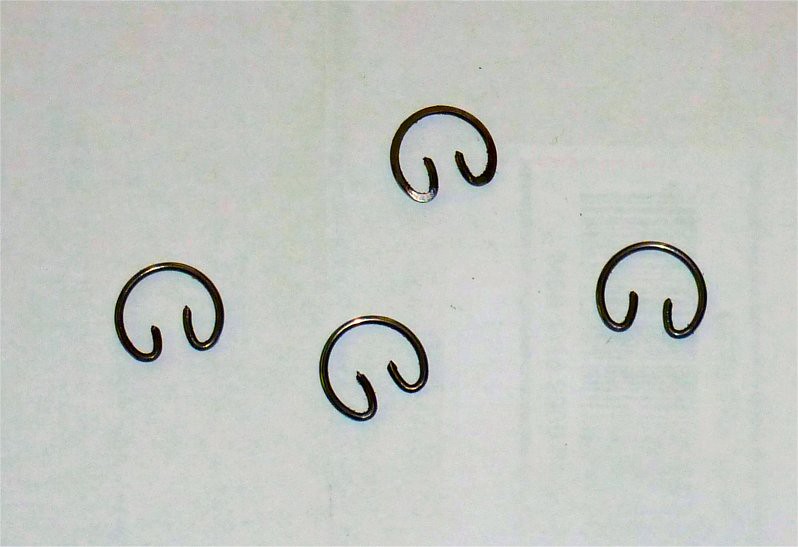

Heres the pictures of the circlips below. You can see the scoring on the one that popped out. These circlips below, do NOT impress me. I think they are marginally sufficient. Certainly if they don't pop out on every person that uses them, you can always argue the machanic didn't seat them fully in their groove. I would say that I did seat them all properly, but I think the real test of these circlips is how often they pop out across a large number of users, NOT just one user (me) I think these are crap...

here's all 4 circlips below:

Here's the one that popped loose in all it's glory. It's not quite the same as the one WZ507 posted a picture of, now is it..???

To Jim Comstock... Thank you for that link you posted. It mentioned a lot of factors that I hadn't considered and gave me a good perspective on how certain tollerances effect the forces applied to the rods, pistons, wristpins, and eventually the circlips. It's certainly a lot to consider in determining the cause of my (long ago) rebuild failure

Interestingly enough I replaced those wire circlips with cut steel ones in the same pistons and wrist pins, which I assume were designed to recieve the wire circlips. They haven't popped out in over 20 years of riding...

Anglophile said:o0norton0o said:From a physics point of view, I would argue that the weight of the return wire on the ends of the wire circlips can act as a bob-weight to compress the circlip as it changes direction

Right, inertia not g-forces. Sorry, just being nit-picky

..... but I didn't say G-forces did I?? If anything I should have said "mass" of the return wire... not weight. Of course it's inertial force and not gravity. Who said it was gravity???

WZ507 said:As usual Comnoz is spot on and likely a bit too gentle when he says “I don't think I would say all wire circlips are no good”.

and neither did I say that all wire circlips are no good, just the ones I got with the pistons I bought. (I'll post pictures of the circlips in question and even the damaged circlip that popped out, which I saved)

WZ507 said:To repeat what others have already stated, the round wire circlip is the lowest mass keeper and literally all that is used nowadays on modern pistons, especially in performance applications. I believe the round wire circlip is used exclusively by Wiseco/JE on the myriad piston designs and millions of pistons they sell. It might not be the best design out there, just way ahead of whatever is in 2nd place (how's that for being diplomatic).

When properly installed in the correct piston groove and employed with the correct wrist pin design, the round wire circlip is never (I know, never say never) going to be dislodged and the only way to remove the pin with the wire in place is to destroy the piston.

With a properly matched piston, circlip and wrist pin, as shown below, it is virtually impossible to push the pin past the circlip, as any force causing the wrist pin to impinge on the circlip, wedges the circlip into the groove, causing the circlip to embed even further into the piston, thus the piston must literally be destroyed before the pin could ever move past it. If you conduct such an experiment in a press, it will destroy the piston before the pin ever moves out of the piston.

Now of course we’ve all experienced issues like you describe (me included) where some doorknob (in my case a PO) put a simple snap ring in a keeper groove cut for a round wire circlip, and when the tapered end of the wrist pin thrust onto the snap ring, the force tipped/flexed the snap ring and easily pushed it out of the groove, freeing the wrist pin to perform cylinder wall damage sufficient to require resleeving the cylinder. Thus another example of mismatched knowledge and parts.

Right, the circlip you posted combined with the groove shape in the piston and shape of the wrist pin look like an excellent system. I have no doubt that Jim Smith's pistons with wire circlips work excellenty, NOR did I ever imply that they didn't work well. Only that the ones I got with my pistons seemed like crap to ME.

Heres the pictures of the circlips below. You can see the scoring on the one that popped out. These circlips below, do NOT impress me. I think they are marginally sufficient. Certainly if they don't pop out on every person that uses them, you can always argue the machanic didn't seat them fully in their groove. I would say that I did seat them all properly, but I think the real test of these circlips is how often they pop out across a large number of users, NOT just one user (me) I think these are crap...

here's all 4 circlips below:

Here's the one that popped loose in all it's glory. It's not quite the same as the one WZ507 posted a picture of, now is it..???

To Jim Comstock... Thank you for that link you posted. It mentioned a lot of factors that I hadn't considered and gave me a good perspective on how certain tollerances effect the forces applied to the rods, pistons, wristpins, and eventually the circlips. It's certainly a lot to consider in determining the cause of my (long ago) rebuild failure

Interestingly enough I replaced those wire circlips with cut steel ones in the same pistons and wrist pins, which I assume were designed to recieve the wire circlips. They haven't popped out in over 20 years of riding...