BruceB

VIP MEMBER

- Joined

- Aug 22, 2023

- Messages

- 10

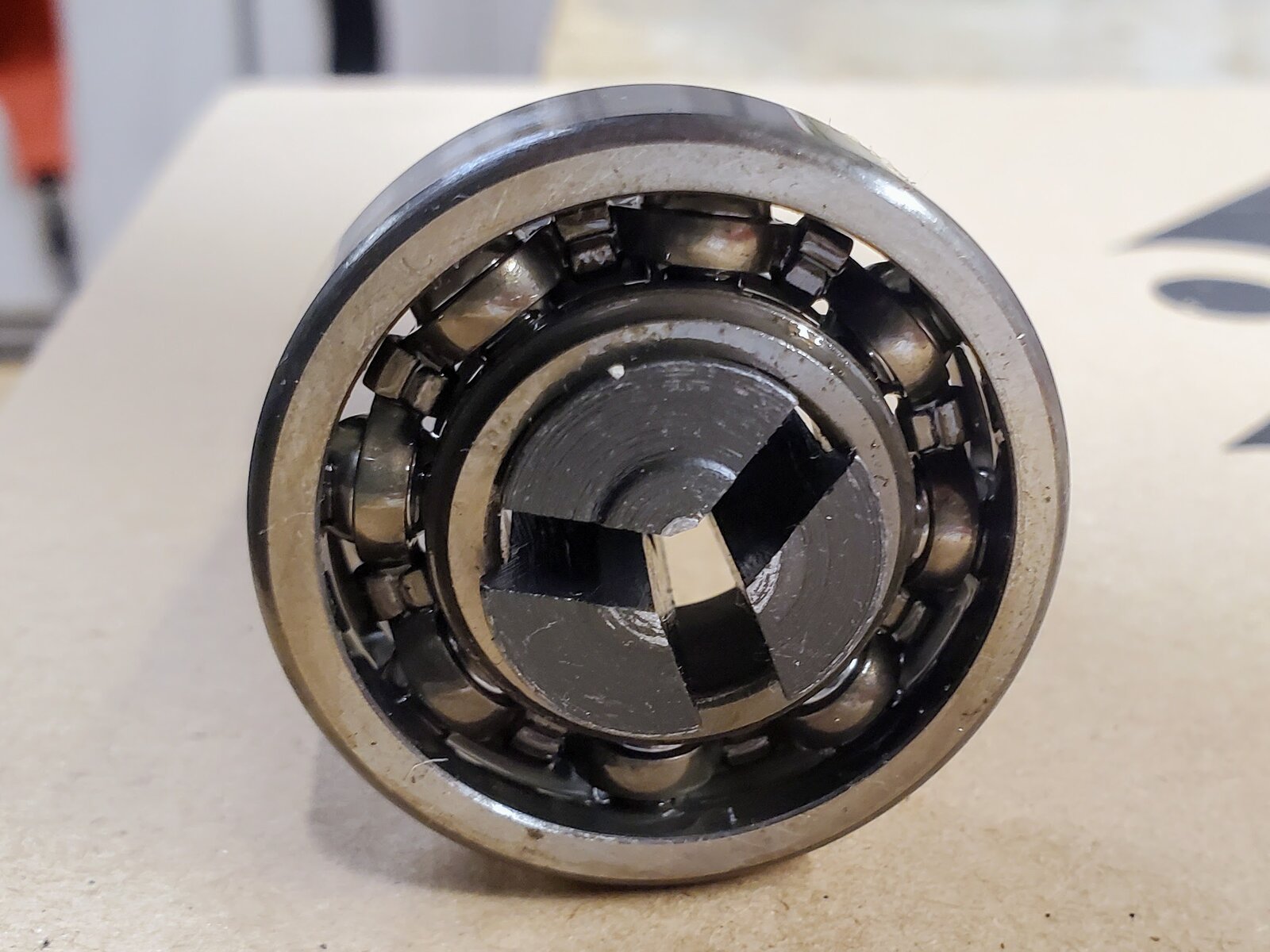

I just replaced my '73 Commando gearbox layshaft bearing and wanted to relay my experience. I think like a lot of owners it's something approached (and delayed!) with trepidation because of the stories of stuck bearings. I certainly went into it with pretty high anxiety. But I had good success and I wanted to let you know what tools and techniques I used. Note that I did all this with the gearbox in the frame. I did also have the primary drive side completely off.

Heat is of course required, but the main problem is how to get the blind hole bearing out. What I used is this collet based slide hammer:

Orion Motor Tech Blind Hole Collet Bearing Race and Seal Puller Extractor Kit

Search on Amazon, it's currently priced at $65 and is an absolute wonder.

I also bought a cheap $25 IR temp sensor from harbor freight, and used a 1400 watt heat gun (500F+) I already had.

I aimed the heat gun at the primary drive side of the case behind the bearing and waited about 15 minutes for the case to reach 220F. I then applied 5 firm but not excessively hard strikes with the slide hammer to the collet and on the 5th strike the bearing popped out. Woohoo, what a relief!

While the case was still hot, I inserted the next size up collet behind the main shaft bearing and similarly it just took a few strikes with the slide hammer and it popped out too.

Just as a further note. I basically did the same to put the new bearings in. Heated the case with the heat gun to 220F, chilled the bearings in the freezer to 0F, and the bearings literally pushed in, with a drift, by hand. I did give them a further tap with a hammer, but they were already home.

Hope this helps.

Heat is of course required, but the main problem is how to get the blind hole bearing out. What I used is this collet based slide hammer:

Orion Motor Tech Blind Hole Collet Bearing Race and Seal Puller Extractor Kit

Search on Amazon, it's currently priced at $65 and is an absolute wonder.

I also bought a cheap $25 IR temp sensor from harbor freight, and used a 1400 watt heat gun (500F+) I already had.

I aimed the heat gun at the primary drive side of the case behind the bearing and waited about 15 minutes for the case to reach 220F. I then applied 5 firm but not excessively hard strikes with the slide hammer to the collet and on the 5th strike the bearing popped out. Woohoo, what a relief!

While the case was still hot, I inserted the next size up collet behind the main shaft bearing and similarly it just took a few strikes with the slide hammer and it popped out too.

Just as a further note. I basically did the same to put the new bearings in. Heated the case with the heat gun to 220F, chilled the bearings in the freezer to 0F, and the bearings literally pushed in, with a drift, by hand. I did give them a further tap with a hammer, but they were already home.

Hope this helps.