In the process of pulling off the chaincase I noticed that the transmission sleeve gear, and therefore the tranny-side sprocket for the rear chain, has about 2 mm of play in it, as in 2mm along the length of the mainshaft. Is this normal? My concern is that it becomes impossible to reliably align the rear chain if the sprocket can just slide out of alignment again. Mind you, it doesn't slide easily - usually takes a good shove to get it to shift, but still...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sleeve gear / sprocket end play (2008)

- Thread starter Scheffy.G

- Start date

- Status

- Not open for further replies.

- Joined

- May 7, 2005

- Messages

- 6,937

The mainshaft should have no end play as on the other end of the mainshaft there is a nut that pulls it into the ball bearing it runs in which is in the inner cover. Either the nut is loose or the bearing is shot, in either case you need to investigate further but inside the gearbox, start by taking the out cover off and the clutch lift mechanism.

The mainshaft itself doesn't have any play, it's just the sleeve gear that goes over the mainshaft and holds the front drive chain sprocket that's moving. Looking at the parts diagram I don't see any shims or anything to really adjust the end play but it seems strange to leave that much play in it when rear chain wear is a concern.

Scheffy.G, I think the big 040070 sprocket nut securely clamps the sleeve gear to the inner race of the 040098 sleeve gear bearing. Maybe the bearing outer race has lost its press-fit in the trans housing, and you are actually sliding the outer race in and out 2mm with the shaft? I understand it's quite common to loose that press fit.

jimbo

VIP MEMBER

- Joined

- Sep 25, 2004

- Messages

- 1,923

What do you do if the press fit is lost? My inner primary case has wear marks from the sleeve gear sprocket nut rubbing on it . It appear5s the sleeve gear is starting to come out of the trans. The only way I can see that happening is by the transmission bearing bore face is wearing allowing the sleeve gear to move out towards the inner primary.The sleeve gear bearing has lost its fit in the trans and can be moved in and out easily .Scheffy.G, I think the big 040070 sprocket nut securely clamps the sleeve gear to the inner race of the 040098 sleeve gear bearing. Maybe the bearing outer race has lost its press-fit in the trans housing, and you are actually sliding the outer race in and out 2mm with the shaft? I understand it's quite common to loose that press fit.

jimbo

VIP MEMBER

- Joined

- Sep 25, 2004

- Messages

- 1,923

I did, and took another apart today. The second is a low mileage example with good fits, I will probably use, though I would like to figure out why the sleeve gear is moving outward on the original. I find nothing horrible, except the slip bearing fit.Open the trans up & have a look. I doubt it’s as dire as that.

jimbo

VIP MEMBER

- Joined

- Sep 25, 2004

- Messages

- 1,923

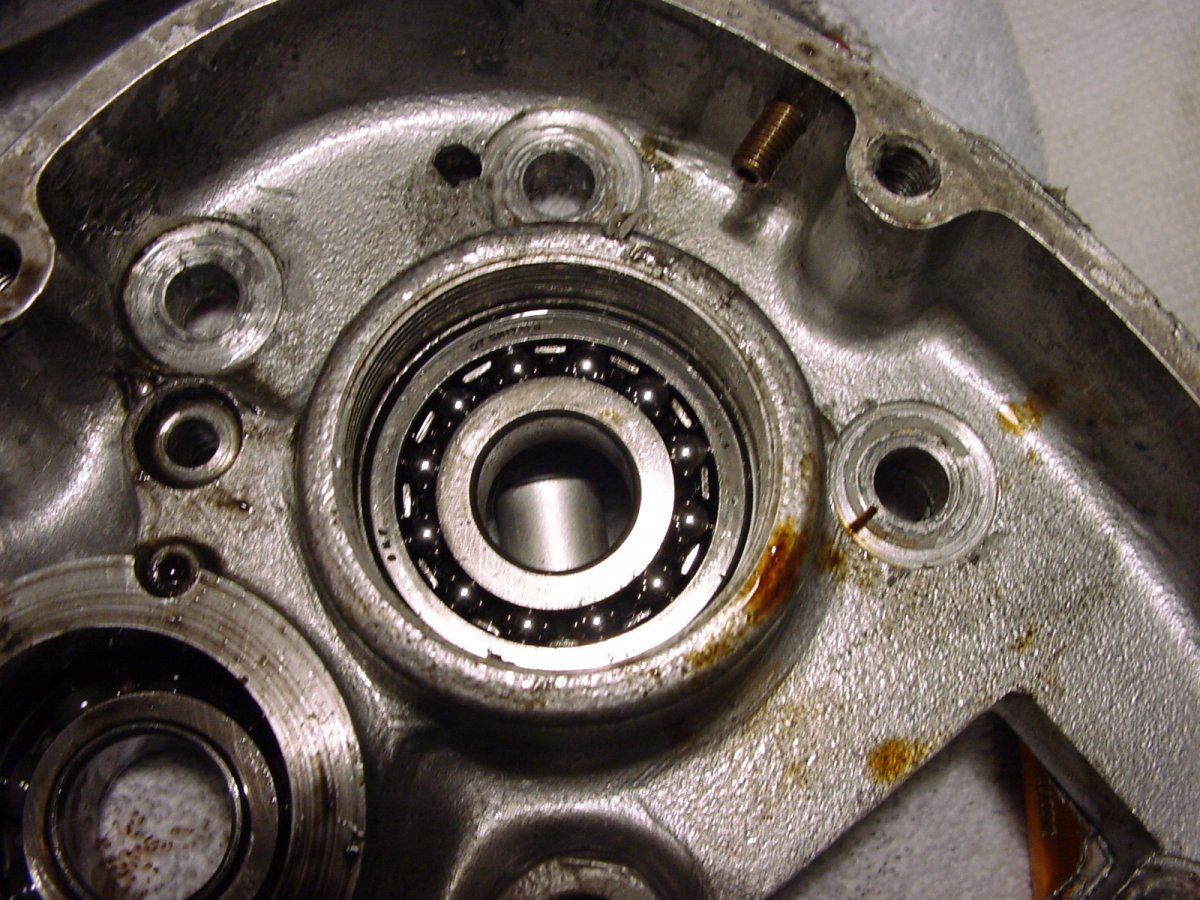

heres some photos of the rub on the inner c case and the sleeve gear nut rub area. I measured both sleeve gear protrusions and they were both the same on both the high and low mileage transmission examples. However the high mileage sleeve bearing has slop. And the T case sleeve gear bearing bore ID is now a loose fit. The clutch wire clip locator was deformed, maybe causing the mainshaft nut when tightened to pull the sleeve gear out towards the inner c case? I also found a self aligning bearing I installed on the cover side main shaft years ago, anybody know of that?

jimbo

VIP MEMBER

- Joined

- Sep 25, 2004

- Messages

- 1,923

MK3 yepIs this a MkIII? Trying to identify the primary chaincase.

Ron L

VIP MEMBER

- Joined

- Feb 27, 2004

- Messages

- 3,217

I would think this would deform the aluminum chaincase rather than pull the sleeve gear out (but would allow the case to bear against the sprocket nut). If the sleeve gear bearing is loose in the bore, I would suspect a cracked case or perhaps some one has removed/replaced the bearing from the case without warming the case and hogged out the bore. It is not uncommon for the case to crack between the mainshaft and layshaft bearing bores. And the MkIII was prone to layshaft bearing failure (infamous Portugese bearing).The clutch wire clip locator was deformed, maybe causing the mainshaft nut when tightened to pull the sleeve gear out towards the inner c case?

jimbo

VIP MEMBER

- Joined

- Sep 25, 2004

- Messages

- 1,923

No cracks seen and the Portuguese bearing was replaced years ago. Not sure about heating the cases when I removed the bearing and rebuilt it years ago, but I believe I would have heated it .I would think this would deform the aluminum chaincase rather than pull the sleeve gear out (but would allow the case to bear against the sprocket nut). If the sleeve gear bearing is loose in the bore, I would suspect a cracked case or perhaps some one has removed/replaced the bearing from the case without warming the case and hogged out the bore. It is not uncommon for the case to crack between the mainshaft and layshaft bearing bores. And the MkIII was prone to layshaft bearing failure (infamous Portugese bearing).

- Joined

- Jul 10, 2008

- Messages

- 61

I had the same issue as the OP which was due to the sleeve gear with bearing attached sliding in and out of the bearing housing. Others on here have shown pics of various mechanical ways of locking the bearing in place. Some have described using loctite between the bearing and its housing. Maybe search "loose sleeve gear bearing" or something like that. I ended up buying a new case, because I also had cracks through the case.

jimbo

VIP MEMBER

- Joined

- Sep 25, 2004

- Messages

- 1,923

thanks for the advise, using the search engine on this website to find anything particular is hard. But otherwise the site is wonderful ! I am using another t case.I had the same issue as the OP which was due to the sleeve gear with bearing attached sliding in and out of the bearing housing. Others on here have shown pics of various mechanical ways of locking the bearing in place. Some have described using loctite between the bearing and its housing. Maybe search "loose sleeve gear bearing" or something like that. I ended up buying a new case, because I also had cracks through the case.

jimbo

VIP MEMBER

- Joined

- Sep 25, 2004

- Messages

- 1,923

When you had the trouble was the sprocket nut grooving the inner primary cover?I had the same issue as the OP which was due to the sleeve gear with bearing attached sliding in and out of the bearing housing. Others on here have shown pics of various mechanical ways of locking the bearing in place. Some have described using loctite between the bearing and its housing. Maybe search "loose sleeve gear bearing" or something like that. I ended up buying a new case, because I also had cracks through the case.

- Status

- Not open for further replies.