- Joined

- Nov 26, 2009

- Messages

- 3,216

I’ve been going through a lot of cams lately and came up with some notes for helping engine builders set up their valve arrangements per cam lift/duration.

Most stock heads have about .185" between the valves when they are on the seats. Race cams have more lift and so the valves come into closer proximity when both valves are off the seat (overlap) and not enough clearance will result in valve clash. You need a safety margin of .040” clearance between the valves at this point. Make your measurement with a bent length of wire inserted through the exhaust port, a tiny flashlight and good eyesight or magnification.

The hotter the cam the less clearance you will have and most race cams barely provide enough clearance with the stock valve setup. Installing larger valves always requires re-angling. Sometimes you can go 1.5mm larger with just an intake valve if you lower the valve into the seat, but deepening the valve seat too much will hurt gas flow by tightening the radius of the port floor.

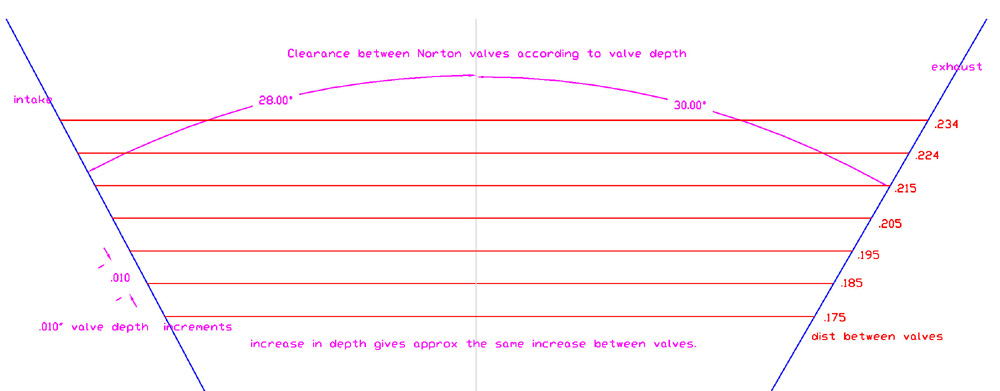

Deepening the valve seat by X” will correspondingly increase the distance between the seats approximately the same amount.

Hot cams such as the D+ or 7s will probably have less than .040” clearance when both valve are off the seats the same amount (overlap). For these hot cams the lifters are up about .165 to .170" near TDC and you will only have about .030” clearance between the valves when the same valves have .185” between them on the seats.

For hot cams – installing bigger valves is impossible without re-angling. You may need .200” or more between the valves on the seats for really hot cams such as the 7s or sifton 480

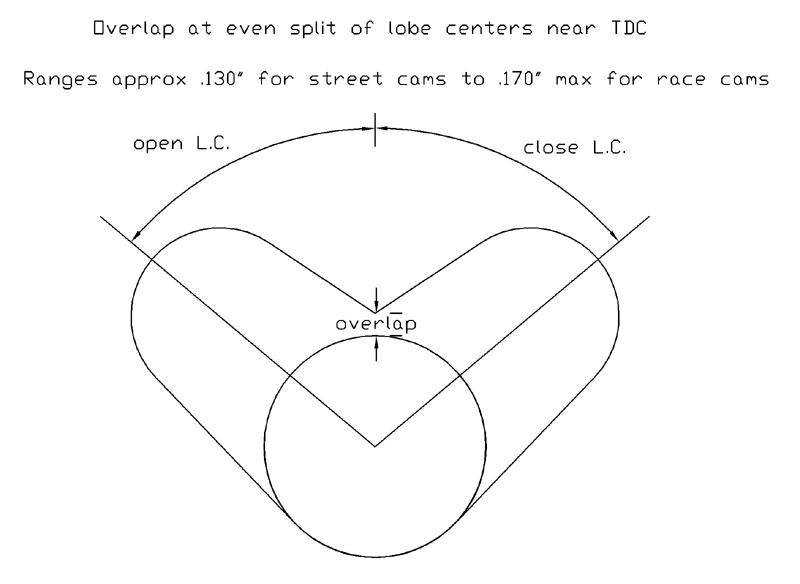

The thing to pay attention to is the lobe/lifter height near TDC when both valves are the same height. This overlap height varies from around .150 to .170” with race cams.

For a stock head with about .185” between the valves on the seats.

.170” overlap would have approx .025 valve clash clearance with w .005” tappet clearance.

.165 overlap would have approx .030 valve clash clearance with w .005” tappet clearance.

.160 overlap would have approx .035 valve clash clearance with w .005” tappet clearance.

.155 overlap would have approx .040 valve clash clearance with w .005” tappet clearance.

.150 overlap would have approx .045 valve clash clearance with w .005” tappet clearance.

You can make this overlap measurement easily with a cam doctor or you can make up a simple V block jig with dial indicators as below. You can also mount a pointer and degree wheel for measuring duration and lobe center separation.

Lobe center also controls the overlap height near TDC. The tighter the lobe center (more torque) the higher the overlap height. So cams have to be designed with lobe centers that will give the necessarily clearance. With Nortons you generally push the lobe centers as close as possible until you run out of valve clash clearance and those lobe centers can range from 100 in a stock cam to around 106 or more for a hot race cam (the PW3 has 107 LCs).

Its a lot of math but focusing on the distance between the valves on the seats and the overlap height will tell you if you’re going to have the clearance you need before you decide on big valves, reangling or deepening the valve seats. Paying attention to these numbers will give you a clue before you mock you motor up for checking.

Expect some measurement variations cause by spring pressure etc.

Most stock heads have about .185" between the valves when they are on the seats. Race cams have more lift and so the valves come into closer proximity when both valves are off the seat (overlap) and not enough clearance will result in valve clash. You need a safety margin of .040” clearance between the valves at this point. Make your measurement with a bent length of wire inserted through the exhaust port, a tiny flashlight and good eyesight or magnification.

The hotter the cam the less clearance you will have and most race cams barely provide enough clearance with the stock valve setup. Installing larger valves always requires re-angling. Sometimes you can go 1.5mm larger with just an intake valve if you lower the valve into the seat, but deepening the valve seat too much will hurt gas flow by tightening the radius of the port floor.

Deepening the valve seat by X” will correspondingly increase the distance between the seats approximately the same amount.

Hot cams such as the D+ or 7s will probably have less than .040” clearance when both valve are off the seats the same amount (overlap). For these hot cams the lifters are up about .165 to .170" near TDC and you will only have about .030” clearance between the valves when the same valves have .185” between them on the seats.

For hot cams – installing bigger valves is impossible without re-angling. You may need .200” or more between the valves on the seats for really hot cams such as the 7s or sifton 480

The thing to pay attention to is the lobe/lifter height near TDC when both valves are the same height. This overlap height varies from around .150 to .170” with race cams.

For a stock head with about .185” between the valves on the seats.

.170” overlap would have approx .025 valve clash clearance with w .005” tappet clearance.

.165 overlap would have approx .030 valve clash clearance with w .005” tappet clearance.

.160 overlap would have approx .035 valve clash clearance with w .005” tappet clearance.

.155 overlap would have approx .040 valve clash clearance with w .005” tappet clearance.

.150 overlap would have approx .045 valve clash clearance with w .005” tappet clearance.

You can make this overlap measurement easily with a cam doctor or you can make up a simple V block jig with dial indicators as below. You can also mount a pointer and degree wheel for measuring duration and lobe center separation.

Lobe center also controls the overlap height near TDC. The tighter the lobe center (more torque) the higher the overlap height. So cams have to be designed with lobe centers that will give the necessarily clearance. With Nortons you generally push the lobe centers as close as possible until you run out of valve clash clearance and those lobe centers can range from 100 in a stock cam to around 106 or more for a hot race cam (the PW3 has 107 LCs).

Its a lot of math but focusing on the distance between the valves on the seats and the overlap height will tell you if you’re going to have the clearance you need before you decide on big valves, reangling or deepening the valve seats. Paying attention to these numbers will give you a clue before you mock you motor up for checking.

Expect some measurement variations cause by spring pressure etc.

Last edited: