Guest viewing is limited

- You have a limited number of page views remaining

- 3 guest views remaining

- Register (free) now to remove this limitation

- Already a member? Click here to login

running in of 850

- Thread starter Head

- Start date

- Status

- Not open for further replies.

robs ss

VIP MEMBER

- Joined

- Aug 16, 2016

- Messages

- 4,035

Others will give the numbers you want but...

I had been advised by someone whose knowledge I value to use a lower grade (eg Castrol GTX) "running in" oil for the first 500-1000 miles.

I did that before changing to Royal Purple HPS 20-50 (@comnoz did an excellent and exhaustive test of oils - it came out on top)

Cheers

I had been advised by someone whose knowledge I value to use a lower grade (eg Castrol GTX) "running in" oil for the first 500-1000 miles.

I did that before changing to Royal Purple HPS 20-50 (@comnoz did an excellent and exhaustive test of oils - it came out on top)

Cheers

- Joined

- Nov 11, 2013

- Messages

- 5,412

The man who has built more of the best parts available for Commados than most others has said,

start it and run it around 2500 until I feel heat in the barrels and then ride it with heavy throttle but short shifts for 1/2 hour before I let it idle. After that the sky is the limit.

I tried to follow his advice.

start it and run it around 2500 until I feel heat in the barrels and then ride it with heavy throttle but short shifts for 1/2 hour before I let it idle. After that the sky is the limit.

I tried to follow his advice.

- Joined

- Nov 11, 2013

- Messages

- 5,412

The most important thing is cam wear on these bikes new, and the factory instructions don't cover that.

Not that the OP has a new cam.

Other thing to note on a rebuild is to

Not that the OP has a new cam.

Other thing to note on a rebuild is to

- Tighten the exhaust roses when hot

- retorque head and base after each of the first few heat cycles, and then 100 and 500 mi.

- Check all of the other fasteners often

baz

VIP MEMBER

- Joined

- May 26, 2010

- Messages

- 8,375

The last build I did on my 750 I used running in oil I'd never bothered before with the stuff but it seems to have worked

My bike barely uses any oil and it's used pretty hard

Do not let it idle at all

Take it out and thrash it in short bursts

Keep tightening everything down

If you baby it on good oil it can take forever for the rings to bed in

My bike barely uses any oil and it's used pretty hard

Do not let it idle at all

Take it out and thrash it in short bursts

Keep tightening everything down

If you baby it on good oil it can take forever for the rings to bed in

If you tighten the base nuts would not that make the 4 long through bolts loose ? Just a question. IanThe most important thing is cam wear on these bikes new, and the factory instructions don't cover that.

Not that the OP has a new cam.

Other thing to note on a rebuild is to

- Tighten the exhaust roses when hot

- retorque head and base after each of the first few heat cycles, and then 100 and 500 mi.

- Check all of the other fasteners often

- Joined

- Nov 11, 2013

- Messages

- 5,412

Prolly better than all of them being loose.If you tighten the base nuts would not that make the 4 long through bolts loose ? Just a question. Ian

click

VIP MEMBER

- Joined

- Dec 27, 2008

- Messages

- 1,024

A fellow Irish Manwell folks i have a 74 commando, just fitted new pistons,rings,plus 40, new valves and guides and seals,new gaskets , what is the running in period and revs on motor and speed and for how long thanks folks

I have run in procedures from SRM in Wales, I'll see if I can find it tonight & PM it over to you.

The folks on this site have unbelievable knowledge so you won't go wrong with any of the advice given.

concours

VIP MEMBER

- Joined

- Dec 29, 2011

- Messages

- 9,888

Have a jacket/helmet & gloves ON when you first start it. Cam needs to be run-in with NO idling. 2,000 engine RPM minimum. As Kommando mentioned, loading the rings is crucial. Don't mamby-pamby the engine, ride it hard, short bursts, do NOT let it overheat. (idling/traffic/etc.)

JMWO

JMWO

- Joined

- Jan 31, 2010

- Messages

- 3,170

From what I understand, the cam/lifters were not replaced so no need for a "cam break-in" procedure. I would just do whichever engine break-in method you prefer. Frankly, anything from the owner's manual break-in procedure to the "Ride it like you stole it" method seems to work fine. I always use something about 1/2 in between!

Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 22,395

Likewise. Don’t Labour it. Don’t redline it. Anything in between will be perfectly fine.From what I understand, the cam/lifters were not replaced so no need for a "cam break-in" procedure. I would just do whichever engine break-in method you prefer. Frankly, anything from the owner's manual break-in procedure to the "Ride it like you stole it" method seems to work fine. I always use something about 1/2 in between!

click

VIP MEMBER

- Joined

- Dec 27, 2008

- Messages

- 1,024

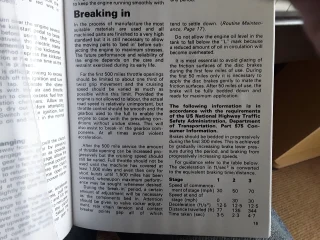

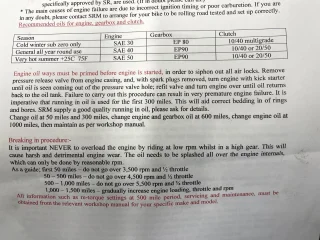

Here's the SRM run-in guidelines, again it's only a guide, main thing is not to 'lug' the engine.A fellow Irish Man

I have run in procedures from SRM in Wales, I'll see if I can find it tonight & PM it over to you.

The folks on this site have unbelievable knowledge so you won't go wrong with any of the advice given.

Attachments

Onder

VIP MEMBER

- Joined

- May 11, 2010

- Messages

- 4,380

If you live in the Republic then your ambient temps will let you run Castrol 20-50 Classic without worry as long as you don't go for long periods between oil changes. I find it one of the more cost effective oils. Sure, Royal Purple is better oil but on this side of the pond it is rather pricey.

- Joined

- Feb 12, 2013

- Messages

- 1,563

Ride it hard and soft. If you have a winding hill with short straights and tight corners, that's the best way. No need to lug it or over rev it, just be firm with it. Never used running in oil myself.

Don't piss around trying to make it idle. Get on the thing and give it heaps with the above in mind.

Some say ride it like you stole it, but gentler.

Don't piss around trying to make it idle. Get on the thing and give it heaps with the above in mind.

Some say ride it like you stole it, but gentler.

Hi all,

May I suggest that I believe running in an engine is the subject of many myths, paranoias and false information.

I am not suggesting im an expert but I have considerable aircraft engine handling experience and I would say the following.

Lycoming recommend engines be run in at high power settings, at or above 75% max power (refer to performance tables). This would equate to full throttle condition, running at redline (2700rpm), at a density altitude (read height above sea level on an average day) of around 8000’. Mixture strength is to be set at the full rich condition or at least 150’ rich of peak exhaust temperature. Of course this would be impractical on our Nortons as they are in a much higher state of tune than aero engines but it does indicate the importance of not ‘babying them’ and them and not have our carburettors running lean. I would attempt to have plenty of goodly throttle openings in the 3 to 4 thousand rpm ranges.

Aero engines certainly run much hotter during the break-in period both in their cylinder head temps (CHT) and oil temps. I suspect this is not only because of the increased friction of surfaces mating together but also because of the reduced lubricity of the running in oil.

Lycoming state that running in is complete when oil consumption stabilises (ideally less than a litre every 10 hours from my experience but sometimes it is much more).

As our engines are also air cooled, it is fundamentally important not to have them get excessively hot, so choosing the correct day and traffic conditions is a pretty good start. I guess the perfect mountain road, full of ups and downs on a cooler day would be ideal.

As suggested, use a very basic mineral oil to start with,to assist bedding in ( controlled wear) of running components.

Minimise time spent idling and of course don’t over rev the engine.

Don't labour the engine.

Contrary to popular belief, expose your engine to high combustion pressures, that is applying considerable load (throttle opening) to the engine at medium revs but vary the load to minimise hotspots and higher CHTs. The combustion pressure forces the rings against the bore and assists with bedding in and prevents glazing.

I would suggest that 90% of the running occurs within the first few hours and by 20 hours your bike should be ready for anything.

Change oil to your premium oil of choice (high zinc?), cut open the filter and inspect for contamination then ride and enjoy.

To summarise what I have said, ride your bike normally paying particular attention to it’s temperature and don’t be afraid of spirited riding, whilst avoiding the extremes of the engine performance envelope. I hope this makes sense.

I suspect that many problems that are attributed to incorrect running in are the result of poorly rebuilt engines or faulty component.

Apologises to the numerous references to aero technology but the similarities probably exceed the differences, other than the quality of the materials used.

Alan

May I suggest that I believe running in an engine is the subject of many myths, paranoias and false information.

I am not suggesting im an expert but I have considerable aircraft engine handling experience and I would say the following.

Lycoming recommend engines be run in at high power settings, at or above 75% max power (refer to performance tables). This would equate to full throttle condition, running at redline (2700rpm), at a density altitude (read height above sea level on an average day) of around 8000’. Mixture strength is to be set at the full rich condition or at least 150’ rich of peak exhaust temperature. Of course this would be impractical on our Nortons as they are in a much higher state of tune than aero engines but it does indicate the importance of not ‘babying them’ and them and not have our carburettors running lean. I would attempt to have plenty of goodly throttle openings in the 3 to 4 thousand rpm ranges.

Aero engines certainly run much hotter during the break-in period both in their cylinder head temps (CHT) and oil temps. I suspect this is not only because of the increased friction of surfaces mating together but also because of the reduced lubricity of the running in oil.

Lycoming state that running in is complete when oil consumption stabilises (ideally less than a litre every 10 hours from my experience but sometimes it is much more).

As our engines are also air cooled, it is fundamentally important not to have them get excessively hot, so choosing the correct day and traffic conditions is a pretty good start. I guess the perfect mountain road, full of ups and downs on a cooler day would be ideal.

As suggested, use a very basic mineral oil to start with,to assist bedding in ( controlled wear) of running components.

Minimise time spent idling and of course don’t over rev the engine.

Don't labour the engine.

Contrary to popular belief, expose your engine to high combustion pressures, that is applying considerable load (throttle opening) to the engine at medium revs but vary the load to minimise hotspots and higher CHTs. The combustion pressure forces the rings against the bore and assists with bedding in and prevents glazing.

I would suggest that 90% of the running occurs within the first few hours and by 20 hours your bike should be ready for anything.

Change oil to your premium oil of choice (high zinc?), cut open the filter and inspect for contamination then ride and enjoy.

To summarise what I have said, ride your bike normally paying particular attention to it’s temperature and don’t be afraid of spirited riding, whilst avoiding the extremes of the engine performance envelope. I hope this makes sense.

I suspect that many problems that are attributed to incorrect running in are the result of poorly rebuilt engines or faulty component.

Apologises to the numerous references to aero technology but the similarities probably exceed the differences, other than the quality of the materials used.

Alan

Last edited:

baz

VIP MEMBER

- Joined

- May 26, 2010

- Messages

- 8,375

Times have changed since the old days

I can remember seeing cars as a kid with a "running in" sign on the back lugging along in top gear low revs 35 mph

And workshop manuals with do not exceed 30 mph then 40mph for a set time bla bla

Just recently well ten years ago or so my mate bought a new CCM

This bike has a Suzuki engine ,he had it delivered to his house because he didn't want to take it on a motorway from brand new!!

Old habits die hard I guess

I would have caned it in bursts all the way home

I can remember seeing cars as a kid with a "running in" sign on the back lugging along in top gear low revs 35 mph

And workshop manuals with do not exceed 30 mph then 40mph for a set time bla bla

Just recently well ten years ago or so my mate bought a new CCM

This bike has a Suzuki engine ,he had it delivered to his house because he didn't want to take it on a motorway from brand new!!

Old habits die hard I guess

I would have caned it in bursts all the way home

- Status

- Not open for further replies.

Similar threads

- Replies

- 36

- Views

- 3,624

- Replies

- 29

- Views

- 3,396

- Replies

- 27

- Views

- 4,087

- Replies

- 13

- Views

- 1,781

- Replies

- 4

- Views

- 1,410