I like using the putoline chain wax (bath of hot wax) and alternating with a freshly cleaned/waxed chain every 500 miles or so. A bit old fashioned but economical and seems like an easy way to get good results. So - tightening up the rear axle yesterday (1973 750) i noticed the end of the spindle on the brake side is a good 4 or 5 threads up inside the spindle nut ? The bolt up rear spindle arrangement is still a bit of a mystery to me - is this typical or should i be riding home slowly tonight ? Can i slacken off the spindle on the other side and pull it through by tightening the nut on the drive side if it is in 3 parts ? ? :?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rear wheel spindle nut

- Thread starter stu

- Start date

- Status

- Not open for further replies.

- Joined

- Oct 29, 2006

- Messages

- 1,075

It's normal. Don't worry about it. There are plenty of threads engaged. The standard acceptable thread engagement is that the length of threads engaged has to be at least the diameter of the fastener. IOW, if the outside diameter of the threaded portion is 5/16" then 5/16" worth of threaded length has to be in or through the nut. Since the nut in question is quite deep, there are sufficient threads engaged.

- Joined

- Oct 19, 2005

- Messages

- 18,978

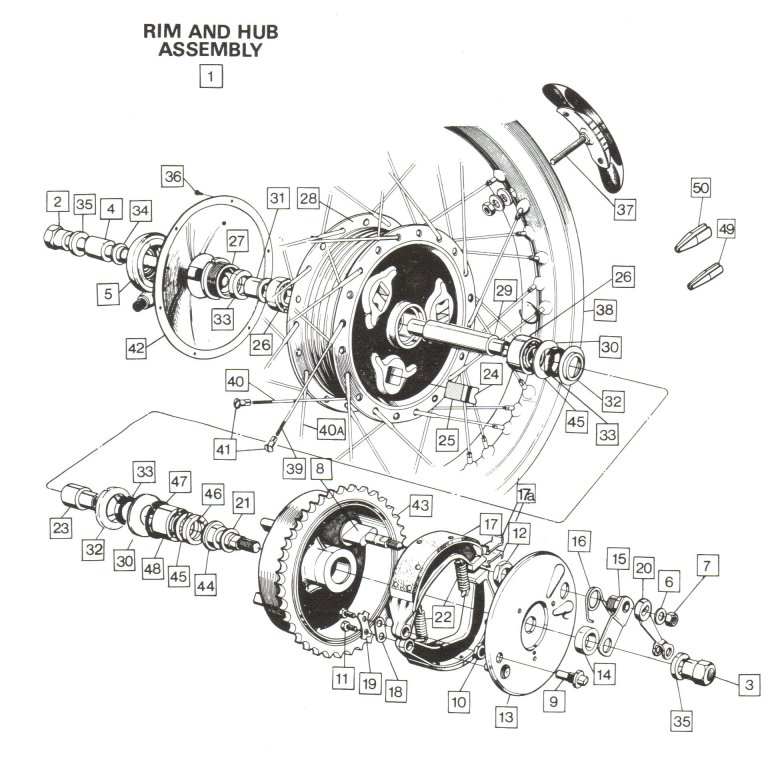

Confusing description and terminology so here's exploded view to help ID in universal language of parts numbers, unless a molested case. Rear set up leaves me fuzzy headed too. You are definitely at more risk of radioactive fission of long axle if not all snug and stable. Let all the aire out of rear for a sense of what a fractured axle on the fly feels like though not that bad slowing down but really nutzo to get moving again. If still riding it then should some how prevent long axle break loss of clamp force from being pulled to rear of slot and retained sidewise so long axle don't just slip right out. Hose clamp and tape, zip ties and wire have gotten me going twice now away from home but rode home 60 miles last year or 35 miles '04 to rent truck to go most of 1000 miles home.

tag this URL for numbers and names.

http://www.oldbritts.com/nor_comm_73_20.html

There's a long TS axle and a short DS stub, dummy or 'Stupid' axle that long axle screws into the shortie. If you are getting alternating slack when nipping up alternate sides then I'd suspect issue in the drum dual row bearing condition and its retaining circlip. If the paddle cushions stand too proud, ie: over 1/8" out the wheel hub face, that can also cause some shifting on tightening either side. Routine is install axles loose, get chain tension and wheel aligned then stomp on and hold rear brake to center drum then nip up dumb axle pretty good then the long axle. Less than 1/4" gap should be seen between wheel hub and drum.

tag this URL for numbers and names.

http://www.oldbritts.com/nor_comm_73_20.html

There's a long TS axle and a short DS stub, dummy or 'Stupid' axle that long axle screws into the shortie. If you are getting alternating slack when nipping up alternate sides then I'd suspect issue in the drum dual row bearing condition and its retaining circlip. If the paddle cushions stand too proud, ie: over 1/8" out the wheel hub face, that can also cause some shifting on tightening either side. Routine is install axles loose, get chain tension and wheel aligned then stomp on and hold rear brake to center drum then nip up dumb axle pretty good then the long axle. Less than 1/4" gap should be seen between wheel hub and drum.

- Joined

- Dec 28, 2009

- Messages

- 5,155

Yes, stand on brake pedal to tighten up dummy axle first ,then long axle fit and tighten. If shifting occurs suspect double row bearing circlip popped out ,some slots for it were too tightly machined.You should inspect and regrease the bearing here anyways every time apart. It's awkward to get at so fit a sealed type .

- Status

- Not open for further replies.