You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pictures of inter cams

- Thread starter Dano

- Start date

- Status

- Not open for further replies.

Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 20,659

First question has to be: what oil are you using?

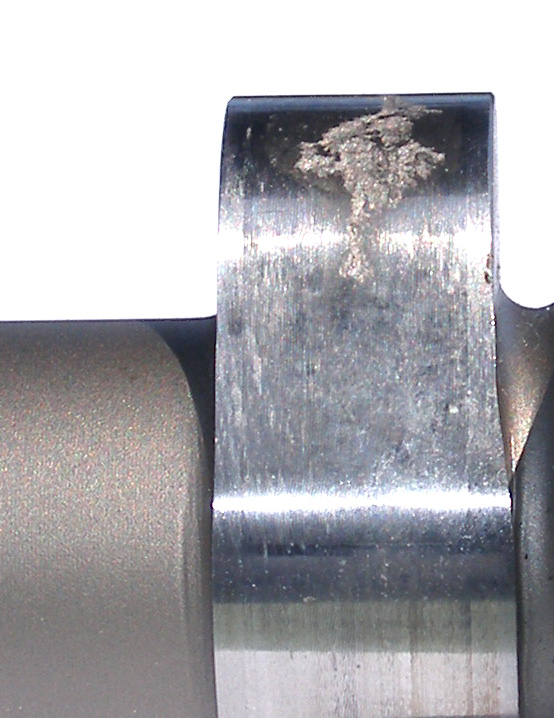

Left hand lobe just looks like poor lubrication to me. If that’s all there was, then that’s what I’d gues. But right the hand lobe looks much more worrying! Where did all those bits of metal (stelite I presume) go?

I assume it’s a welded up cam? I guess a faulty welding process should be considered, although I imagine you’d say it was done by a preputable firm and its therefore a low probability for you. Still worth thinking about though...

So, the second thought for me would be excessive valve float / chatter / hammering, caused by inadequate valve control, ie the valve springs not doing their job correctly (check out Comstocks spintron videos if you haven’t already, very insightful as to what can go on up there)!

Third thought for me would be valve spring installation, are you sure the springs aren’t going coil bound? Or the spring retainers are hitting the top of the guide (I know a well respected engine builder and racer who chased his arse for ages looking at cam wear and it was the spring retainers hitting the guides cos he’d gradually increased cam lift).

But it’s your motor... what are your thoughts...?

Left hand lobe just looks like poor lubrication to me. If that’s all there was, then that’s what I’d gues. But right the hand lobe looks much more worrying! Where did all those bits of metal (stelite I presume) go?

I assume it’s a welded up cam? I guess a faulty welding process should be considered, although I imagine you’d say it was done by a preputable firm and its therefore a low probability for you. Still worth thinking about though...

So, the second thought for me would be excessive valve float / chatter / hammering, caused by inadequate valve control, ie the valve springs not doing their job correctly (check out Comstocks spintron videos if you haven’t already, very insightful as to what can go on up there)!

Third thought for me would be valve spring installation, are you sure the springs aren’t going coil bound? Or the spring retainers are hitting the top of the guide (I know a well respected engine builder and racer who chased his arse for ages looking at cam wear and it was the spring retainers hitting the guides cos he’d gradually increased cam lift).

But it’s your motor... what are your thoughts...?

Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 20,659

Who made and/or supplied the cam and followers?

As they’ve both been re surfaced, isn’t that kinda irrelevant ?

- Joined

- Apr 8, 2011

- Messages

- 45

Oil I am using is Castrol Edge 25-50 (non synthetic). Suitable to use with methanol. The cams (probably original) I had built up by a very reputable firm. Don't know what material was used but will find out. It is a race bike and I might have over revved it couple of times. Valve springs are not very old and we're within specs when installed. Will check if springs are bottoming out.The cam with most damage is the first along the line to get the oil.

Cams and followers probably original. Both have been built up at the same time.

Cams and followers probably original. Both have been built up at the same time.

- Joined

- Dec 14, 2013

- Messages

- 397

I had a similar issue with Manx cams/followers from three different suppliers, the left side looks like lack of oil or oil not up to the job right, had side could be bad resurface job and lack of oil or not correct oil for the job, causing more severe failure.

Appears the cams and or followers are not running square to each other, which will give uneven loadings on both, resulting in early failure, I always check the Manx before running with bearing blue, and after running for piece of mind that the bearing surfaces are 100%, if not I bin them .

Manx OHC engines like lots of oil to the cams, so would think Inters would be similar, also check oil supply, only buy cams and followers from the good guys with lots of experience with said engine.

I would not buy resurfaced cams or followers for these engines unless I got some very good feed back from actual users that are using them successfully for racing.

And again oil is very important I am currently running a very hi zinc oil in the Manx and all seems good, witness marks on the cams and followers need to be full contact, not half contact or wavy as in the left lobe, which starts at the right moves towards the centre of the lobe and back to the right which would result in very heavy point loading, ie lack of bearing contact.

Plus all above by Fast Eddie.

I have no experience with Inters or SOHC Manxes by the way.

Burgs

Appears the cams and or followers are not running square to each other, which will give uneven loadings on both, resulting in early failure, I always check the Manx before running with bearing blue, and after running for piece of mind that the bearing surfaces are 100%, if not I bin them .

Manx OHC engines like lots of oil to the cams, so would think Inters would be similar, also check oil supply, only buy cams and followers from the good guys with lots of experience with said engine.

I would not buy resurfaced cams or followers for these engines unless I got some very good feed back from actual users that are using them successfully for racing.

And again oil is very important I am currently running a very hi zinc oil in the Manx and all seems good, witness marks on the cams and followers need to be full contact, not half contact or wavy as in the left lobe, which starts at the right moves towards the centre of the lobe and back to the right which would result in very heavy point loading, ie lack of bearing contact.

Plus all above by Fast Eddie.

I have no experience with Inters or SOHC Manxes by the way.

Burgs

Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 20,659

Oil I am using is Castrol Edge 25-50 (non synthetic). Suitable to use with methanol. The cams (probably original) I had built up by a very reputable firm. Don't know what material was used but will find out. It is a race bike and I might have over revved it couple of times. Valve springs are not very old and we're within specs when installed. Will check if springs are bottoming out.The cam with most damage is the first along the line to get the oil.

Cams and followers probably original. Both have been built up at the same time.

Well Dano, if you haven’t been following it thus far, I’d suggest getting stuck into this thread:

https://www.accessnorton.com/NortonCommando/follower-scar-oil-tests.25898/page-31#post-390580

- Joined

- Jul 25, 2015

- Messages

- 1,180

why not use R that would be the recommended oil for a manx.. but there is another point i would like to raise..

Talking to a bloke who used to build merlins at rolls royce, the cams were hand finished to an exact profile which in practice meant taking around three thou off a lobe with a smooth file and thern the whole thing was polished..

I wonder in practice how accurate machining of cam profiles actually is. Remember Cook Nielson then editor of cycle

testing a number of cam profiles for an XT Yam ... he was very unimpressed so umimpressed that thought he woud stick to Factory cams in future. This little gem is from the mid 70s , have things really improved that much?

Talking to a bloke who used to build merlins at rolls royce, the cams were hand finished to an exact profile which in practice meant taking around three thou off a lobe with a smooth file and thern the whole thing was polished..

I wonder in practice how accurate machining of cam profiles actually is. Remember Cook Nielson then editor of cycle

testing a number of cam profiles for an XT Yam ... he was very unimpressed so umimpressed that thought he woud stick to Factory cams in future. This little gem is from the mid 70s , have things really improved that much?

Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 20,659

This little gem is from the mid 70s, have things really improved that much?

For OEMs of bikes and cars, I’d say yes, things have improved massively.

For cottage industry / after market stuff, I’d be surprised if many have move far...

- Joined

- Apr 13, 2009

- Messages

- 1,778

As they’ve both been re surfaced, isn’t that kinda irrelevant ?

Probably a lot more relevant as a place to start than your theories.

I would have the oil that was in the bike tested and then the cam and followers taken to a metallurgist for testing. You'll learn a lot more than theorising.

Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 20,659

Probably a lot more relevant as a place to start than your theories.

Ken, the OP said he thinks the cams are original. And have been refaced, along with the followers, by a reputable provider of this service.

As ALL of the surfaces concerned have been re surfaced, I do fail to see how the original surface can be at fault here.

But I’m ready to stand corrected as soon as you actually put forward a theory of some sort...

(Just as a reminder, we are talking here about an OHC Norton International).

Last edited:

- Joined

- Apr 13, 2009

- Messages

- 1,778

Ken, the OP said he thinks the cams are original. And have been refaced, along with the followers, by a reputable provider of this service.

As ALL of the surfaces concerned have been re surfaced, I do fail to see how the original surface can be at fault here.

But I’m ready to stand corrected as soon as you actually put forward a theory of some sort...

(Just as a reminder, we are talking here about an OHC Norton International).

Like I said, testing will gain you knowledge that listening to people going on about theories simply won't. Which part of that don't you understand? I don't deal in theories, just facts established by testing. But, hey, what would I know?

Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 20,659

I absolutely agree with you about testing Ken. The part I did not (and still don’t) get was the fact that you felt it very relevant to know whom the original supplier was, whereas I struggle to see the relevance of this aspect still.

You don’t deal in theories Ken? I respectfully suggest that you do sir, one has to have a theory in order to decide what, why and how to conduct tests on. The outcome of which (hopefully) provides the facts one needs in order to act.

Anyway, you’ve made your point about testing the parts and oil, which I am certainly not arguing with, and I don’t want to hijack Dano’s thread here. So, if you feel the need to continue the discussion with me personally, please feel free to do so via a PM.

Let’s hope Dano sorts it out soon. AND that he shares his findings with us all.

You don’t deal in theories Ken? I respectfully suggest that you do sir, one has to have a theory in order to decide what, why and how to conduct tests on. The outcome of which (hopefully) provides the facts one needs in order to act.

Anyway, you’ve made your point about testing the parts and oil, which I am certainly not arguing with, and I don’t want to hijack Dano’s thread here. So, if you feel the need to continue the discussion with me personally, please feel free to do so via a PM.

Let’s hope Dano sorts it out soon. AND that he shares his findings with us all.

Last edited:

- Joined

- Apr 8, 2011

- Messages

- 45

The cams are back at the firm who originally built them up, never thought to get them tested. Burgs- are you saying you would bin my cams and followers because of the uneven wear. The not so bad cam came up looking like new with a quick rub with wet and dry sandpaper.

- Joined

- Dec 14, 2013

- Messages

- 397

Hi Dano

I would if it was mine, might look ok but, there are some good suppliers of Inter cams out there, but you need to check that the new cams and rockers make good contact so you have the maximum bearing surface to reduce bearing stress etc.

Has the cam box had any work done on it, are bearing bores parallel check with bearing blue on the cams as I said before, I do this with only one of the hairspring spings in place so I don't have the engine being turned over by the cams (so much), when checking, I should probably fit a light coil spring.

Does the inter have adjustable oil supply to the over head cams, if so make sure you are getting the correct amount of flow to the cams, I tee a low pressure, pressure gauge in the feed line and set the pressure between 9 and 10 PSI at 2000 Rev/min (as advised by the old guys).

My 1955 Manx has adjustable oil flow, according to the experts only in 1955 short strokes, Ken McIntosh told me to ditch it as they were no good.

The racers I have spoken to in the past said they never had any problems with cams and followers so there must be something different, oils?

Talking to Jack Caruthers back in the early 70s, he said when Kel was racing the Manx he would stick to the redline and have no trouble with the Manx for a whole season, but if he looked like he was in the money he would often over rev the engine, then a rebuild/check was in order for the top end.

Talk to Ken McIntosh if you can he know more than most about these old Nortons, he has been helped me a lot, in the end they are pretty agricultural really.

Burgs

I would if it was mine, might look ok but, there are some good suppliers of Inter cams out there, but you need to check that the new cams and rockers make good contact so you have the maximum bearing surface to reduce bearing stress etc.

Has the cam box had any work done on it, are bearing bores parallel check with bearing blue on the cams as I said before, I do this with only one of the hairspring spings in place so I don't have the engine being turned over by the cams (so much), when checking, I should probably fit a light coil spring.

Does the inter have adjustable oil supply to the over head cams, if so make sure you are getting the correct amount of flow to the cams, I tee a low pressure, pressure gauge in the feed line and set the pressure between 9 and 10 PSI at 2000 Rev/min (as advised by the old guys).

My 1955 Manx has adjustable oil flow, according to the experts only in 1955 short strokes, Ken McIntosh told me to ditch it as they were no good.

The racers I have spoken to in the past said they never had any problems with cams and followers so there must be something different, oils?

Talking to Jack Caruthers back in the early 70s, he said when Kel was racing the Manx he would stick to the redline and have no trouble with the Manx for a whole season, but if he looked like he was in the money he would often over rev the engine, then a rebuild/check was in order for the top end.

Talk to Ken McIntosh if you can he know more than most about these old Nortons, he has been helped me a lot, in the end they are pretty agricultural really.

Burgs

- Joined

- Nov 26, 2009

- Messages

- 3,081

Dano

Look at the similar failure of the lobe below - similar material type and process. Welded cams are usually good but they can be defective on rare occasions.

The only cam material that I have not seen any failures with is plasma nitrided tool steel. They are hard to get.

Look at the similar failure of the lobe below - similar material type and process. Welded cams are usually good but they can be defective on rare occasions.

The only cam material that I have not seen any failures with is plasma nitrided tool steel. They are hard to get.

- Status

- Not open for further replies.