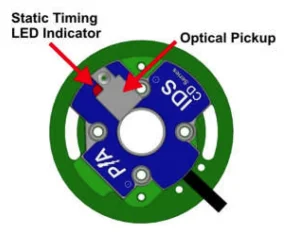

The LED and the timing have been sorted out. Since it was so hard to get the timing disk slot right AND tightened, I went to the Power Arc web site as suggested by gtiller. A natural thing to do (that I was obviously unable to think of myself). The timing became easy then. Back the slot up so that whes tightened it was close. Loosen the ignition module and rotate (so easy to rotate the ignition module -- "so that's why the slots for the ignition module bolts are elongated!". How the obvious becomes obvious once someone points it out. And done. But then it wouldn't fire! No spark. LED works, but no spark at the plug. Fuse blown. I think when tightening down the coil block either the wire I trapped (yes, I Loosened it and moved the wire, but I didn't inspect the wire -- don't remember which it was, but I had tightened the hell out of the bolt) or the when I put the socket and extention up from below to tighten the coil bracket bolts, I didn't see what might be touching what and the mistake -- I think I left the key on. Hope it's just the fuse. Live and learn, but I seem to be "learning" far more than what's really necessary.