- Joined

- Nov 26, 2009

- Messages

- 3,411

It’s taken a couple years with some help from John Andrews cams and his (polynumerical etc) cam design software. But the non symmetrical (asymmentrical) Norton cams are finally here. The point of being non symmetrical is to find the ideal shape for the opening side and also for the closing side, The requirements of each is different. The opening ramp cam be more abrupt as long as you don’t overstress the rocker arm and other cam train components. Changing the opening ramp changes the entire opening side cam profile along with it. The closing side needs a more gentle ramp to bring the valve down softly to prevent valve bounce. Bounce occurs at high RPM and if its too severe then the opening intake valve can tangle with the closing exhaust valve resulting in a damaged head. With too much bounce the exhaust gases will contaminate the intake charge.

You don’t want the closing intake valve to bounce either or you will lose compression and power. Its a balancing act.

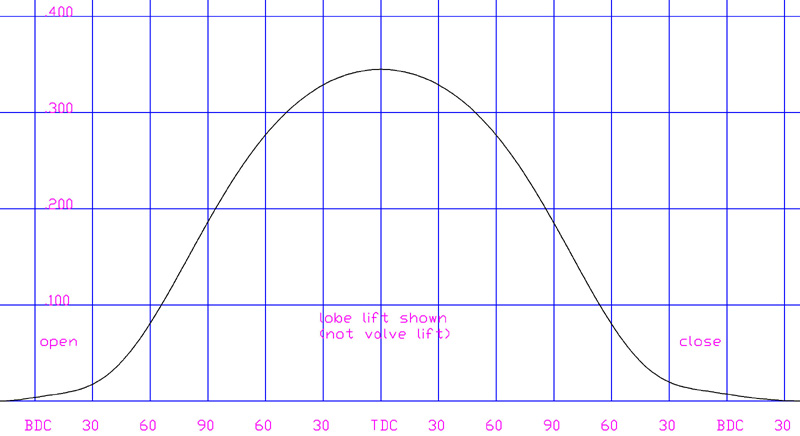

The profile below is close to the lift and duration of a stock Norton cam. If you look closely you can see that the opening ramp on the left is shorter than the closing ramp on the right. Other differences between the opening and closing flanks are too fine to see in the image but all the numbers are different.

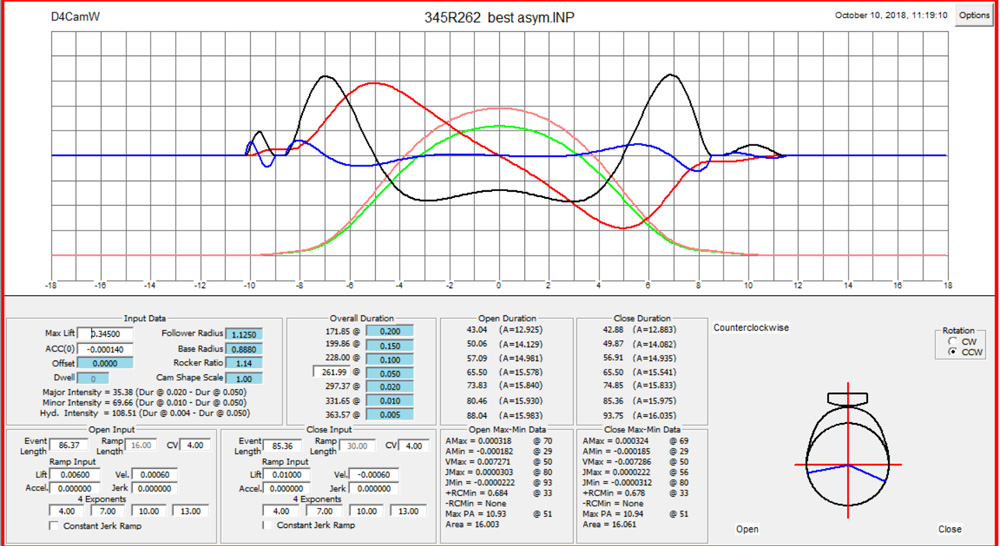

Below is some of the cam software data. On the right side you can see that the closing ramp has a lower jerk curve. You can see the different inputs for the ramps in the lower left corner.

Its not a radical departure from existing Norton cam designs. But its more refined. Easier on the valve train and more efficient.

Plasma nitrided hardened tool steel billets at extra cost for longevity.

You don’t want the closing intake valve to bounce either or you will lose compression and power. Its a balancing act.

The profile below is close to the lift and duration of a stock Norton cam. If you look closely you can see that the opening ramp on the left is shorter than the closing ramp on the right. Other differences between the opening and closing flanks are too fine to see in the image but all the numbers are different.

Below is some of the cam software data. On the right side you can see that the closing ramp has a lower jerk curve. You can see the different inputs for the ramps in the lower left corner.

Its not a radical departure from existing Norton cam designs. But its more refined. Easier on the valve train and more efficient.

Plasma nitrided hardened tool steel billets at extra cost for longevity.

Last edited: