- Joined

- Feb 21, 2013

- Messages

- 121

From many posts on the 2S & 4S I realise that few owners understand the unusual (polydyne) ramp that Norton chose for their Commando performance cams. This post is an attempt to explain it and why it can be bad to use incorrect clearances.

On a high performance engine there is a need to get a greater mass of air/fuel mixture into the engine, and/or the same amount at higher revs. On an naturally aspirated engine this is partly achieved be increasing the angle/area over which the valves are open. To do this efficiently the valves need to be opened and closed more rapidly, which means increasing valve acceleration. With a conventional ramp there is a clearance that needs to be closed up before the valve can begin opening. Upon closing of the gap the follower/push rod/rocker/valve instantaneously have to match the velocity and acceleration of the cam. This causes noise, high loads and compression of the valve train, all of which are undesirable and have to be allowed for in the design. When the valve closes, the valve is still at a significant velocity at high rpm and it hits the valve seat hard and bouncing is a possibility.

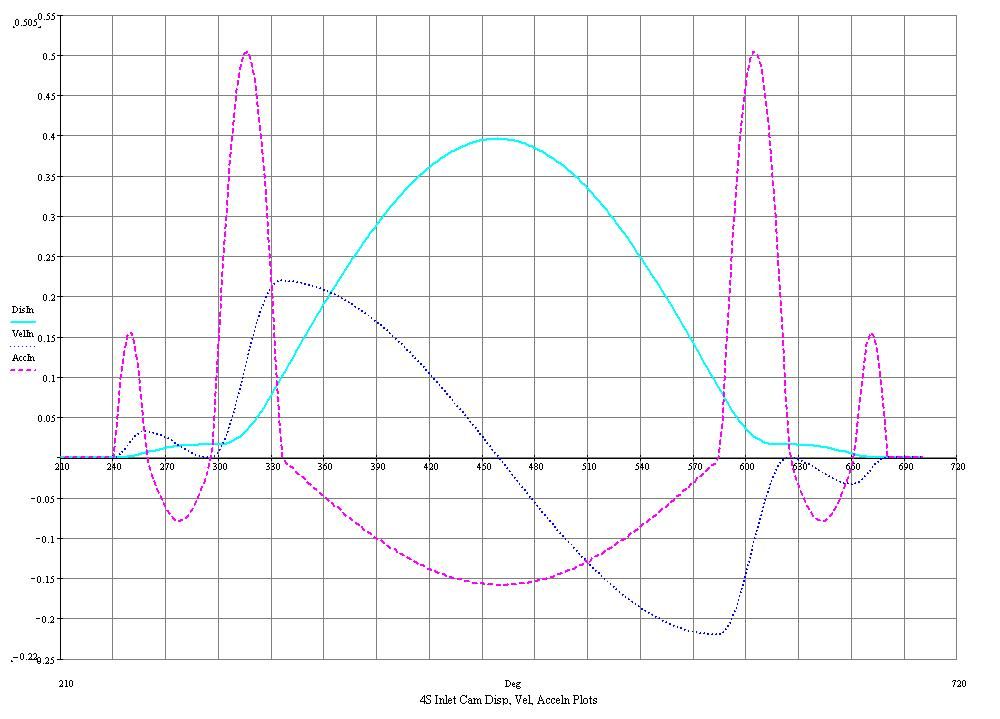

The polydyne ramp is designed to allow for a rapid opening and closing of the valves without any of the sudden impacts that result from the conventional ramps. I have created a graph superimposing the inlet cam lift (green, DisIn, units inch) cam velocity (black, VelIn, units inch/crankshaft radian) and cam acceleration (red, AccIn, units inch/crankshaft radian squared). Don't worry if you don't understand the velocity and acceleration units which I have used, it is not important for understanding this post, I include it only for those readers who studied the sciences and may like to calculate the actual values at any rpm.

The graph shows that at the point the .016" clearance is taken up by the opening ramp the cam velocity and acceleration are both zero, therefore there is NO sudden impact. On the closing curve, as the .016" clearance point is reached and the valve closes, again both the velocity and acceleration have reduced to zero at that point, therefore no sudden impact and there is no possibility of the valve bouncing of the seat.

Now to consider what happens if the wrong clearances are used.

Clearance too small - The valve will begin opening too early and close too late but any performance drop probably won't be noticed with a small error. I can't imagine any harm being done to the inlet but, on the exhaust side the valve will be held slightly open for a relatively long time and that could lead to erosion/burning of the valve/seat as high pressure exhaust gas squeezes through the small gap.

Clearance too large - Due to the high acceleration from the cam above .016" the benefits of the poydyne ramp will be lost and when the clearance is taken up there will be a high impact velocity and sudden acceleration. On closing the valve will hammer onto the seat as with the conventional ramp. Both undesirable.

WARNING - If you use these cams in an engine with aluminium alloy barrels and/or pushrods made from materials other than aluminium alloy you must allow for the different thermal expansion rates of those components when setting the clearances.

On a high performance engine there is a need to get a greater mass of air/fuel mixture into the engine, and/or the same amount at higher revs. On an naturally aspirated engine this is partly achieved be increasing the angle/area over which the valves are open. To do this efficiently the valves need to be opened and closed more rapidly, which means increasing valve acceleration. With a conventional ramp there is a clearance that needs to be closed up before the valve can begin opening. Upon closing of the gap the follower/push rod/rocker/valve instantaneously have to match the velocity and acceleration of the cam. This causes noise, high loads and compression of the valve train, all of which are undesirable and have to be allowed for in the design. When the valve closes, the valve is still at a significant velocity at high rpm and it hits the valve seat hard and bouncing is a possibility.

The polydyne ramp is designed to allow for a rapid opening and closing of the valves without any of the sudden impacts that result from the conventional ramps. I have created a graph superimposing the inlet cam lift (green, DisIn, units inch) cam velocity (black, VelIn, units inch/crankshaft radian) and cam acceleration (red, AccIn, units inch/crankshaft radian squared). Don't worry if you don't understand the velocity and acceleration units which I have used, it is not important for understanding this post, I include it only for those readers who studied the sciences and may like to calculate the actual values at any rpm.

The graph shows that at the point the .016" clearance is taken up by the opening ramp the cam velocity and acceleration are both zero, therefore there is NO sudden impact. On the closing curve, as the .016" clearance point is reached and the valve closes, again both the velocity and acceleration have reduced to zero at that point, therefore no sudden impact and there is no possibility of the valve bouncing of the seat.

Now to consider what happens if the wrong clearances are used.

Clearance too small - The valve will begin opening too early and close too late but any performance drop probably won't be noticed with a small error. I can't imagine any harm being done to the inlet but, on the exhaust side the valve will be held slightly open for a relatively long time and that could lead to erosion/burning of the valve/seat as high pressure exhaust gas squeezes through the small gap.

Clearance too large - Due to the high acceleration from the cam above .016" the benefits of the poydyne ramp will be lost and when the clearance is taken up there will be a high impact velocity and sudden acceleration. On closing the valve will hammer onto the seat as with the conventional ramp. Both undesirable.

WARNING - If you use these cams in an engine with aluminium alloy barrels and/or pushrods made from materials other than aluminium alloy you must allow for the different thermal expansion rates of those components when setting the clearances.