- Joined

- Dec 28, 2008

- Messages

- 2,035

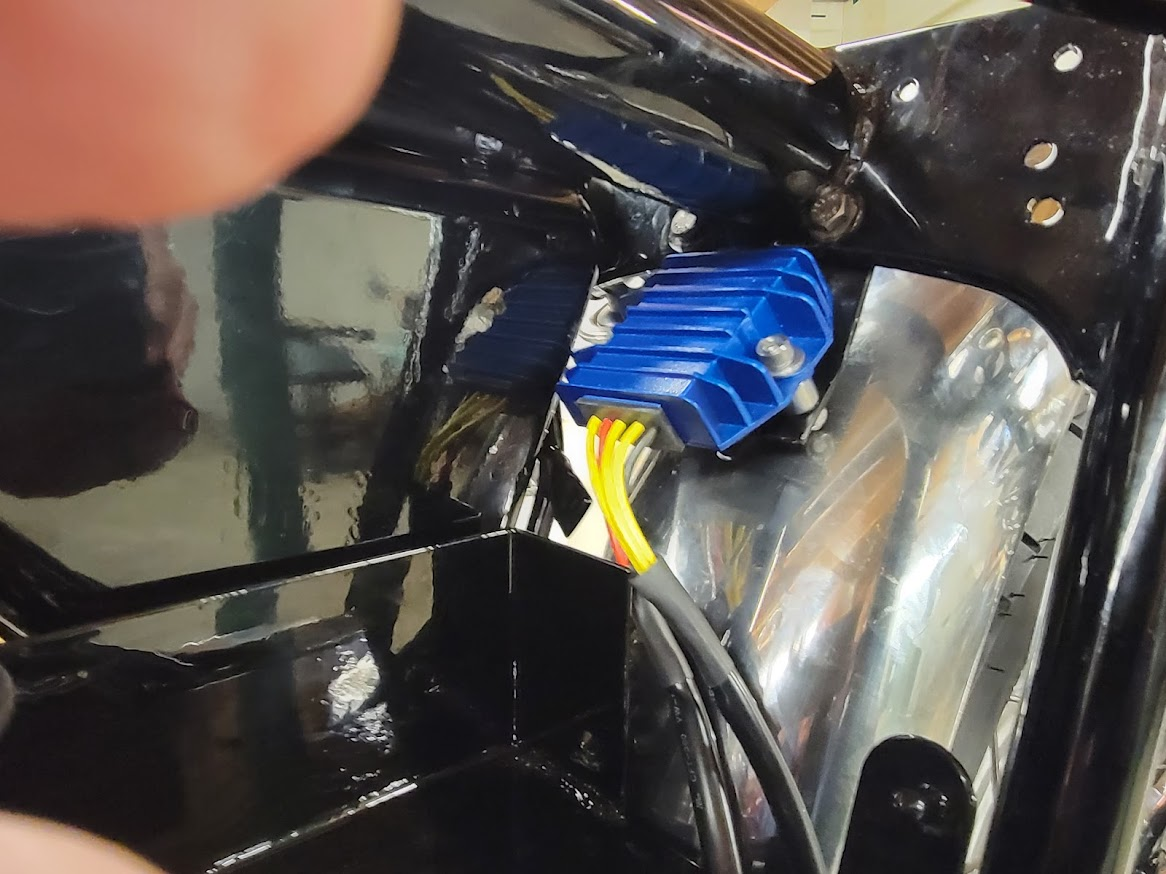

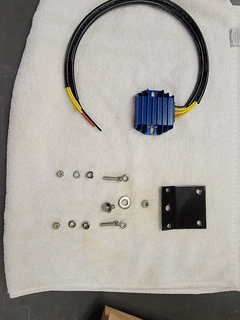

Finding a place for an air cooled part on an air cooled motorcycle can be difficult. Last year a member of this forum gave me the idea I was searching for. I must have spend an hour searching for that post because I wanted to give all the credit for the idea to him. My implementation is different, but both have the same "mother".

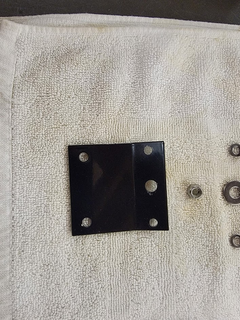

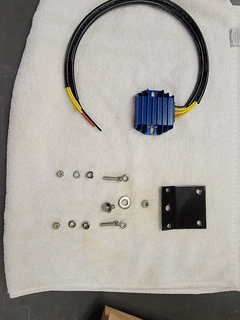

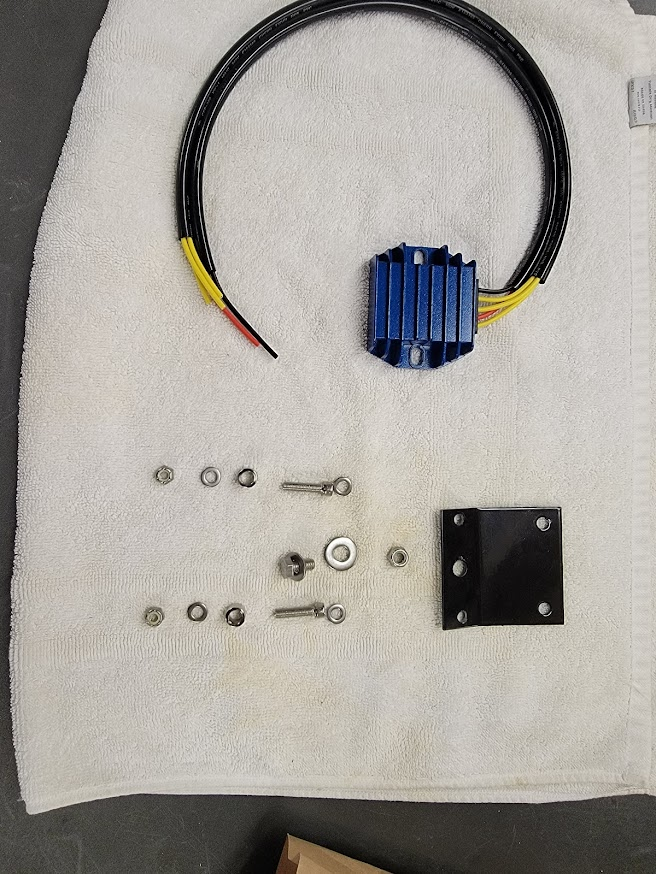

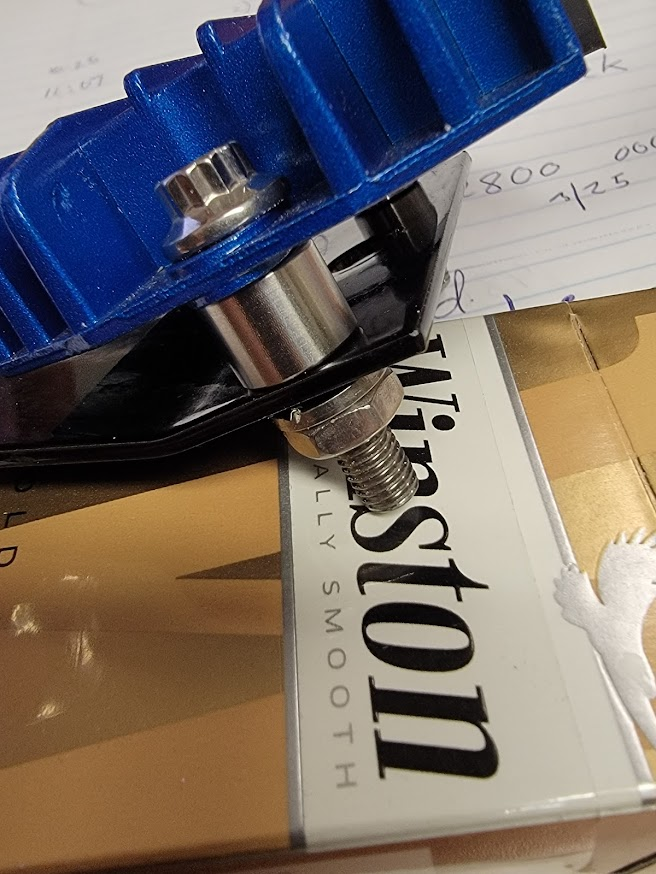

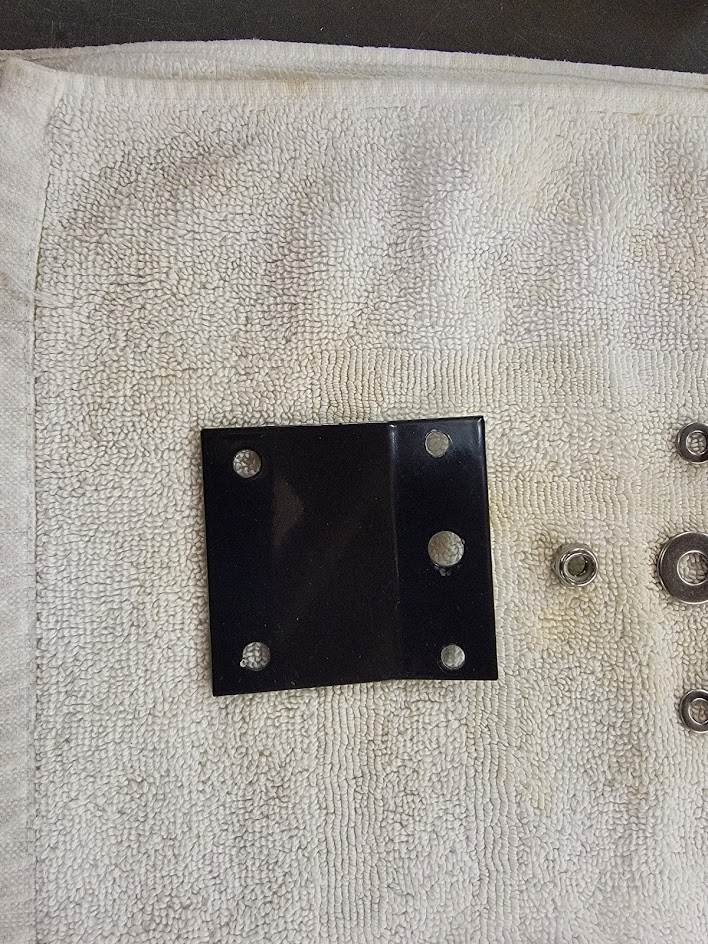

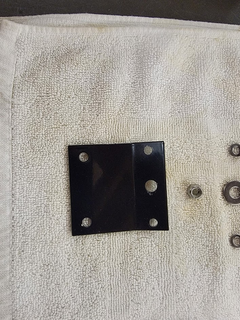

I started with the idea that I would use the rear fender mounting plate, but I'd use 2 fasteners for the Tri-Spark and the 3 that fasten the plate to the motorcycle. Here are the pictures:

I started with the idea that I would use the rear fender mounting plate, but I'd use 2 fasteners for the Tri-Spark and the 3 that fasten the plate to the motorcycle. Here are the pictures: