Jerry Doe

Admin

- Joined

- May 21, 2003

- Messages

- 2,377

Hello all,

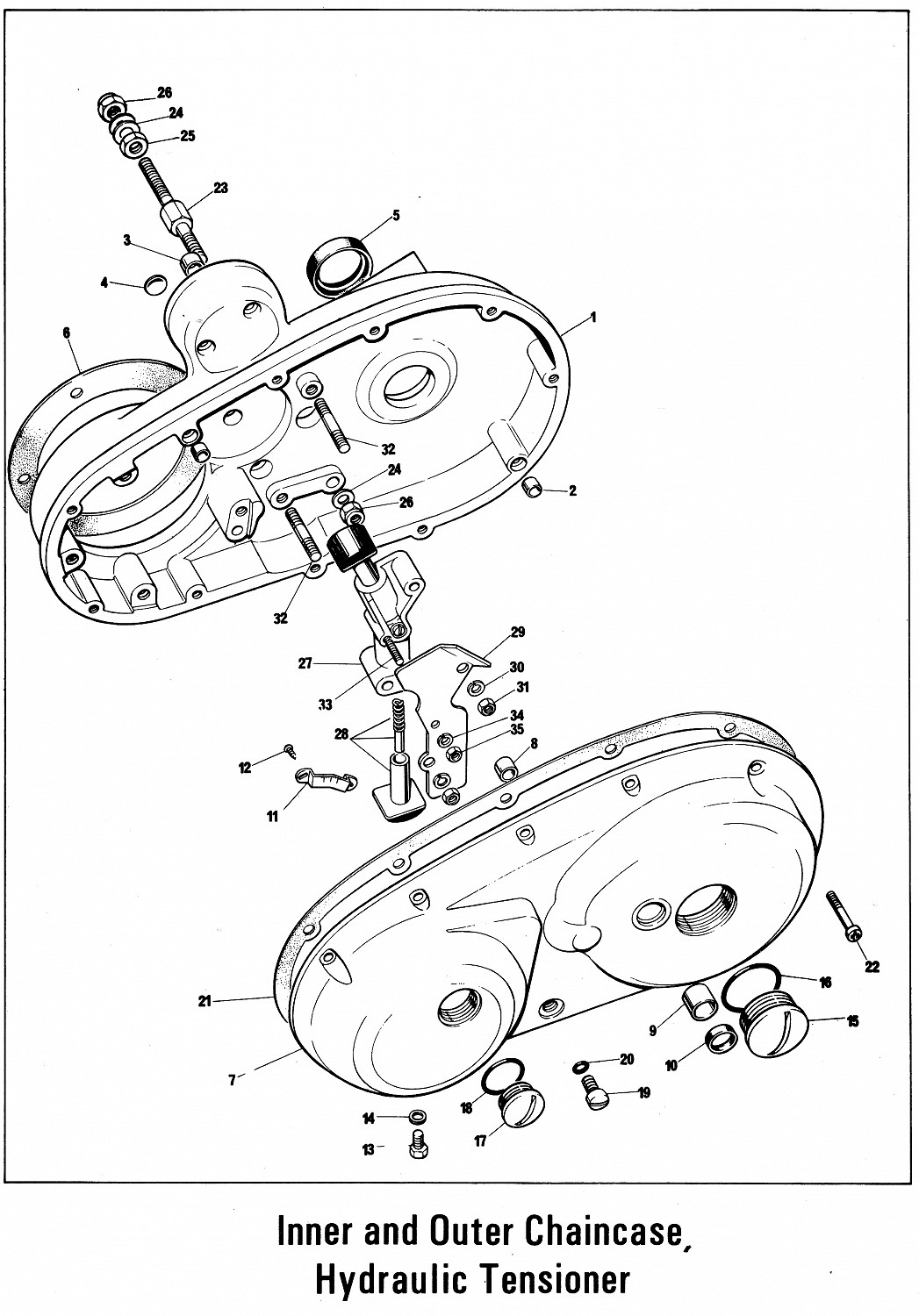

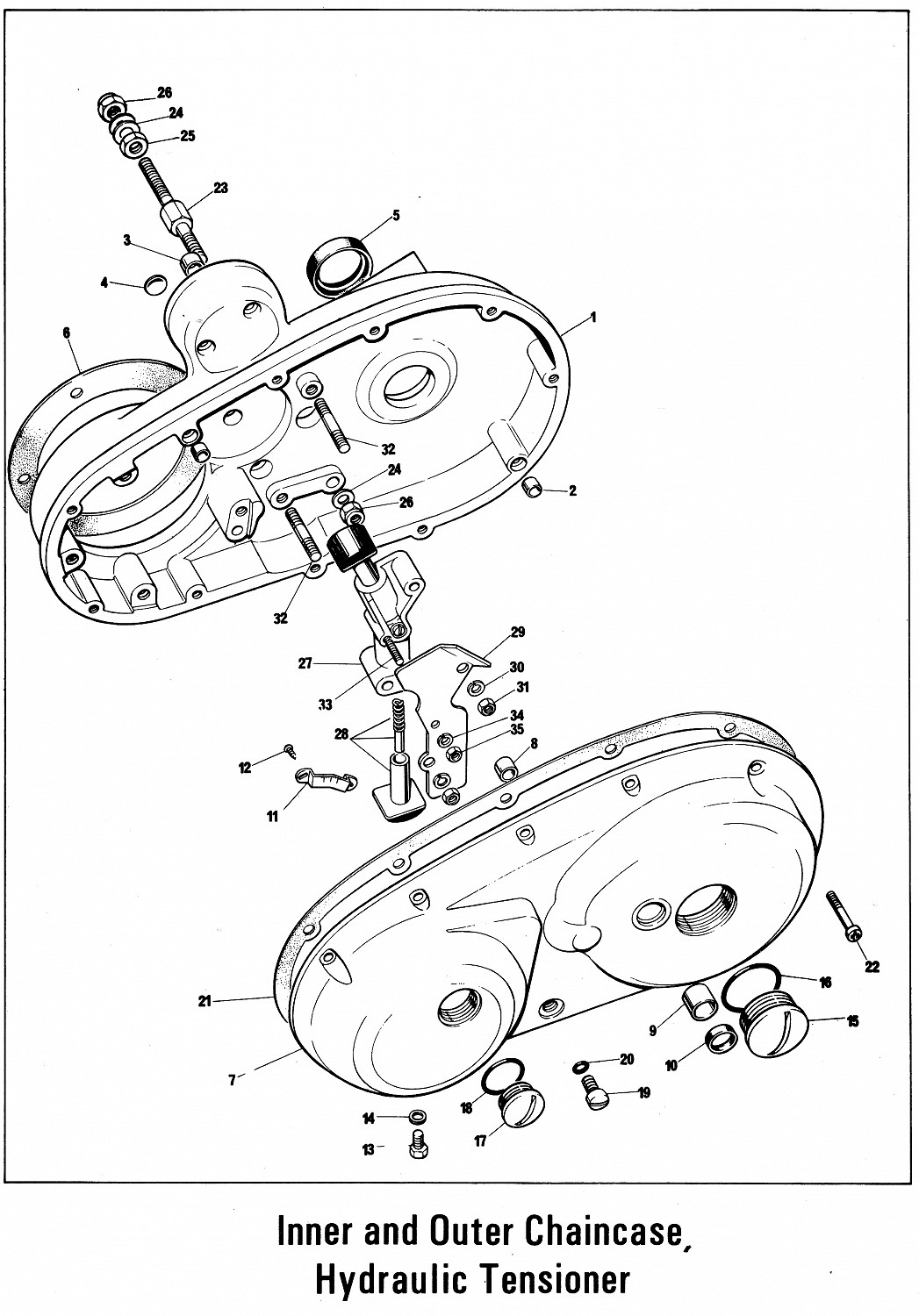

Looking for some advice. My MK3 always has a very small oil leak. Its because the gearbox seems about a 3/16 too far forward and the mainshaft where it goes through the primary to the clutch through oil seal 065956 (the seal in the primary behind the clutch). Its not centering properly in the seal and that is where its leaking from.

Does anyone know any tricks to get the gearbox main shaft centered in the primary seal??

The gearbox wont budge back or forward, tried that.

This is the seal I am talking about, #5

Cheers, Jerry

Looking for some advice. My MK3 always has a very small oil leak. Its because the gearbox seems about a 3/16 too far forward and the mainshaft where it goes through the primary to the clutch through oil seal 065956 (the seal in the primary behind the clutch). Its not centering properly in the seal and that is where its leaking from.

Does anyone know any tricks to get the gearbox main shaft centered in the primary seal??

The gearbox wont budge back or forward, tried that.

This is the seal I am talking about, #5

Andover Norton Parts Drawings - Andover Norton Factory Parts - Commando Parts

Andover Norton Parts are the only Norton spare parts in the market manufactured to original drawings, within the factory-approved tolerances, from the correct materials, and with the correct finish.

andover-norton.co.uk

Cheers, Jerry