- Joined

- Feb 28, 2021

- Messages

- 8

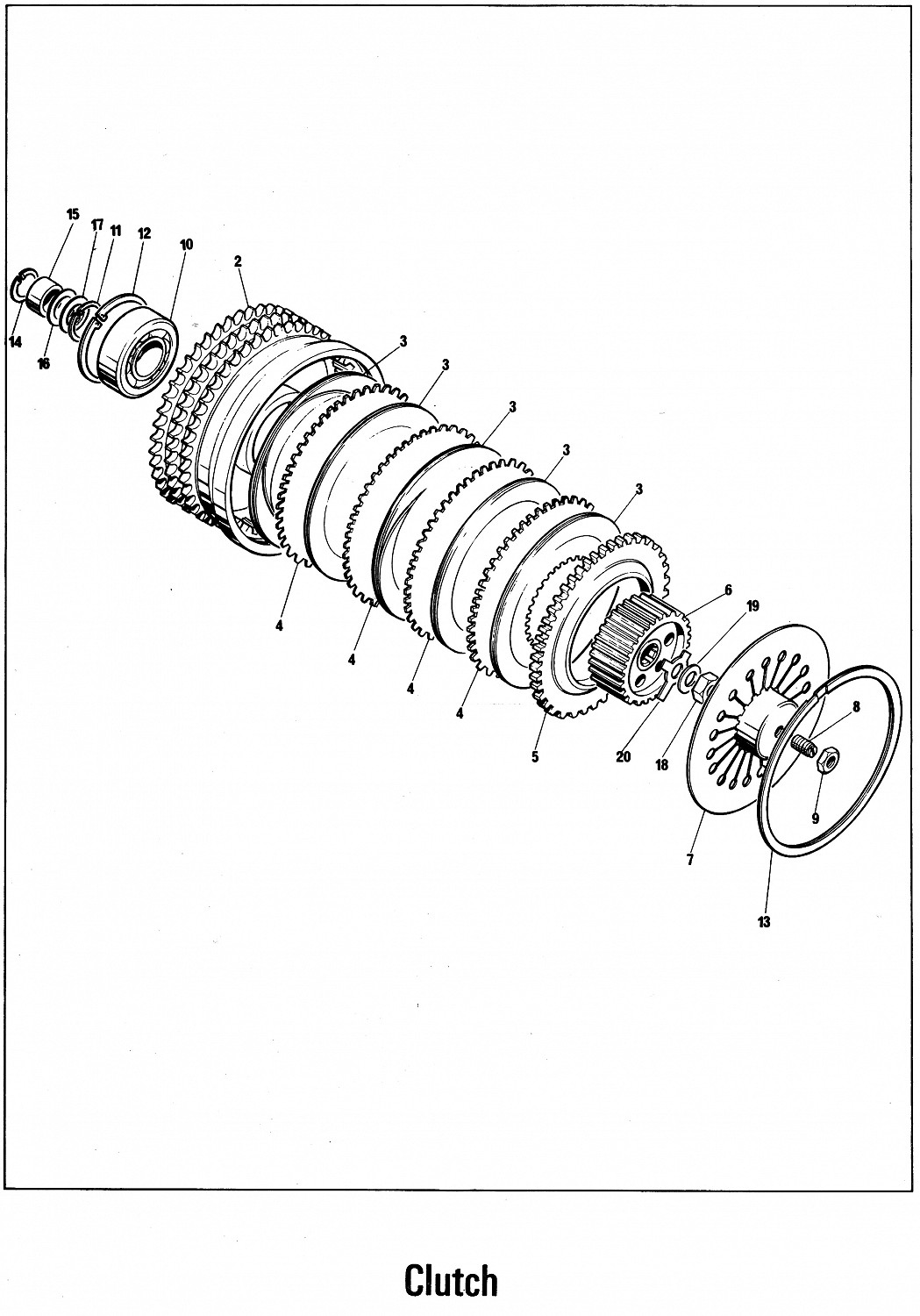

I'm rebuilding my '77 MK3 gearbox and I have just noticed that the circlip on the mainshaft, behind the gearbox sprocket, is missing on the parts catalog (or, at least, I am unable to locate it!).

The old one is bent and I would like to replace it with a new one.

Can somebody give me the part number of it?

Thanks,

Ivo

The old one is bent and I would like to replace it with a new one.

Can somebody give me the part number of it?

Thanks,

Ivo