- Joined

- Aug 8, 2006

- Messages

- 943

Have you guys ever seen anything like this?

I found it rather interesting and seems pretty easy to do.

MAKE YOUR OWN ETHANOL FREE GASOLINE

Ethanol is the scourge of owners of motorcycles, boats, and many other gasoline-operated vehicles and implements. E10 (10% ethanol) is pretty much the only available gasoline in most of the country now, with a few stations offering ethanol-free gas. And E15 (15% ethanol) is coming soon, recently approved by the EPA for 2001 and newer cars - even though the car manufacturers don't want it, and it is not approved for use by any motorcycle manufacturer either. You can thank the ethanol lobby for that.

"E15 won't be a problem - I'll just select my regular E10 on the pump," you may say. Well, there is a problem - the pipes and hose of the fuel pump contain about 3/4 gallon of whatever was last dispensed - and that could be E15. 3/4 gallon isn't much when you're pumping 15 gallons into your car, but when you're only pumping a few gallons into your bike, which doesn't like ethanol to begin with, 3/4 gallon makes a big difference!

What's the problem with ethanol? The biggest problem is phase separation. Like brake fluid, ethanol is hydroscopic, which means it bonds very easily to water. If there is moisture in the air (which there always is), the moisture bonds with the ethanol. The combination of water and ethanol is heavier than gasoline, so it falls to the bottom of the gas tank, where the pickup is. Let your bike sit for any length of time, particularly with a partially-full gas tank (because the air space left will contain moisture, and will expand and contract with heat, sucking in more moisture-laden air), and your tank will have a layer of water/ethanol mixture on the bottom. This is called phase separation. Guess what gets sucked into your engine the next time you start it? The water/ethanol mixture will burn in your engine, but it will burn much leaner and hotter, with the potential for serious engine damage as a result.

Ethanol is particularly corrosive to plastics, rubber, aluminum and fiberglass when compared to straight gasoline. If you have a vintage bike with a fiberglass tank, and are running E10 gasoline in it, the tank is likely swollen and on its way to failure as the ethanol breaks down the fiberglass. Many bikes have developed leaks and problems from swollen gaskets and failed rubber hoses and seals, all as a result of E10.

When E10 is allowed to sit for a long time, particularly somewhere where air can get in, like a normal vented gas tank, the volatile portion of the fuel will eventually evaporate. What's left is a milky goo. This goo eventually hardens into an amber solid, which then cracks into tiny pieces - heading directly into your carburetor to clog jets and cause failures.

Two stroke engines definitely have problems with E10: ethanol breaks down the lubrication provided by the fuel/oil mixture, leading to engine seizures!

So what is the solution? Well, you can check out the web site http://pure-gas.org to try to find a gas station near you that sells ethanol-free gas. Hint: many boat marinas sell ethanol-free gas, because with the added moisture in a boating environment, E10 plays havoc with boat engines.

Or...you can make your own ethanol-free gas. Yes, you heard me right! Make it yourself! I never even thought about doing this, until I read the excellent article "Removing Ethanol from E10 Fuel" by Dave Searle in the December 2012 issue of Motorcycle Consumer News - my absolute favorite magazine. If you haven't got a subscription to this magazine yet, stop reading this right now and go subscribe! I promise you won't be sorry. I've using a few pictures from Dave's article in this article.

So as you can guess, you don't actually make your own gasoline, you take regular E10 gasoline and remove the ethanol. Because ethanol boosts the octane in gasoline, I recommend you start with premium gas. Removing the ethanol from the premium will in the process lower the octane to the equivalent of regular gas. If you start with regular E10, you will need to add an octane booster, available at any auto store, or Wal-Mart.

So how do you remove the ethanol from E10? It's quite simple, actually - just add water! Remember, ethanol binds strongly to water. All you need to do is add some water to the gasoline, agitate to make sure it mixes well, then let it sit for a few minutes. The water will bond with the ethanol, and it will phase-separate out, falling to the bottom of the container.

How much water do you add? Well you can't add too much. If you don't add enough, then it won't remove all of the E10, and what E10 does bond with the water, will separate to the bottom of your container. If you add too much, the available ethanol will bond to the water, and the remaining water will separate to the bottom. You'll then have three layers: gasoline on top, ethanol/water in the middle, and water on the bottom:

Three phase separation

In Dave's article, he used a cheap plastic separatory funnel with a small valve at the bottom, along with a 500cc cylinder for measuring the fuel and a 25cc burette for measuring water:

Measuring instruments

Once filling his funnel with E10, adding water and letting it sit, the water/ethanol separated out, and could be drained using the valve:

Separatory funnel

So how much water do you add? It depends on a few things, including the actual concentration of ethanol (which will vary - it's seldom exactly 10%), and ambient temperature. Dave's testing shows that the optimal amount of water is 2% by volume of the E10. That's 2.56 oz per gallon, or 12.8 ounces for a five-gallon gas can. Remember that extra water will simply separate out, so two cups (16 ounces) of water in a five-gallon gas can is safe. You should use distilled water only, to avoid leaving behind any minerals or other additives that your engine may not like (does fluoride keep your carburetors clean?).

The biggest problem - in what sort of container do you perform this procedure? Dave suggested a five-gallon glass or PET plastic jugs, like those that are found at http://www.midwestsupplies.com - fitted with stopcocks and vent tubes.

My suggestion is a bit simpler: Buy a regular five-gallon gas can:

To the end of the spout, glue several inches of large, transparent PVC pipe:

At the end of the PVC pipe, fasten a valve with a compression fitting:

2-way-plastic-ball-valves-11605-2401007.jpg (11.56 KiB) Viewed 1542 times

Fill the can with E10, add two cups of distilled water, fasten the spout/pipe/valve, shake well, then turn the gas can upside down - fit it in a sawhorse or some other fixture so that the PVC pipe is pointing straight down. You want the absolute lowest point of the gas can to be the outlet for the spout, so that all of the heavier water and ethanol/water moves out the spout and then into the PVC tubing. Wait for the ethanol/water to separate out and drop down into the PVC (you'll see it), then open the valve slightly to drain out the ethanol/water. Once it's drained out, turn the gas can back upright - and you're done!

Ethanol Extraction Rig

So do you want to do this every time you fill up your bike? Probably not. But it's certainly doable for small batches of gasoline for use in small engines (lawn mowers, weed trimmers, any two-stroke engine), to put in your bike just before putting it away for the winter (or for storage of any length of time), or for putting into devices that sit for long periods of time without being run - like backup generators.

I must give credit where due. This is reposted from a Honda Goldwing (GASP!) site called goldwingdocs.com

Read more: http://goldwingdocs.com/forum/viewtopic ... z2DqI5mMWk

I found it rather interesting and seems pretty easy to do.

MAKE YOUR OWN ETHANOL FREE GASOLINE

Ethanol is the scourge of owners of motorcycles, boats, and many other gasoline-operated vehicles and implements. E10 (10% ethanol) is pretty much the only available gasoline in most of the country now, with a few stations offering ethanol-free gas. And E15 (15% ethanol) is coming soon, recently approved by the EPA for 2001 and newer cars - even though the car manufacturers don't want it, and it is not approved for use by any motorcycle manufacturer either. You can thank the ethanol lobby for that.

"E15 won't be a problem - I'll just select my regular E10 on the pump," you may say. Well, there is a problem - the pipes and hose of the fuel pump contain about 3/4 gallon of whatever was last dispensed - and that could be E15. 3/4 gallon isn't much when you're pumping 15 gallons into your car, but when you're only pumping a few gallons into your bike, which doesn't like ethanol to begin with, 3/4 gallon makes a big difference!

What's the problem with ethanol? The biggest problem is phase separation. Like brake fluid, ethanol is hydroscopic, which means it bonds very easily to water. If there is moisture in the air (which there always is), the moisture bonds with the ethanol. The combination of water and ethanol is heavier than gasoline, so it falls to the bottom of the gas tank, where the pickup is. Let your bike sit for any length of time, particularly with a partially-full gas tank (because the air space left will contain moisture, and will expand and contract with heat, sucking in more moisture-laden air), and your tank will have a layer of water/ethanol mixture on the bottom. This is called phase separation. Guess what gets sucked into your engine the next time you start it? The water/ethanol mixture will burn in your engine, but it will burn much leaner and hotter, with the potential for serious engine damage as a result.

Ethanol is particularly corrosive to plastics, rubber, aluminum and fiberglass when compared to straight gasoline. If you have a vintage bike with a fiberglass tank, and are running E10 gasoline in it, the tank is likely swollen and on its way to failure as the ethanol breaks down the fiberglass. Many bikes have developed leaks and problems from swollen gaskets and failed rubber hoses and seals, all as a result of E10.

When E10 is allowed to sit for a long time, particularly somewhere where air can get in, like a normal vented gas tank, the volatile portion of the fuel will eventually evaporate. What's left is a milky goo. This goo eventually hardens into an amber solid, which then cracks into tiny pieces - heading directly into your carburetor to clog jets and cause failures.

Two stroke engines definitely have problems with E10: ethanol breaks down the lubrication provided by the fuel/oil mixture, leading to engine seizures!

So what is the solution? Well, you can check out the web site http://pure-gas.org to try to find a gas station near you that sells ethanol-free gas. Hint: many boat marinas sell ethanol-free gas, because with the added moisture in a boating environment, E10 plays havoc with boat engines.

Or...you can make your own ethanol-free gas. Yes, you heard me right! Make it yourself! I never even thought about doing this, until I read the excellent article "Removing Ethanol from E10 Fuel" by Dave Searle in the December 2012 issue of Motorcycle Consumer News - my absolute favorite magazine. If you haven't got a subscription to this magazine yet, stop reading this right now and go subscribe! I promise you won't be sorry. I've using a few pictures from Dave's article in this article.

So as you can guess, you don't actually make your own gasoline, you take regular E10 gasoline and remove the ethanol. Because ethanol boosts the octane in gasoline, I recommend you start with premium gas. Removing the ethanol from the premium will in the process lower the octane to the equivalent of regular gas. If you start with regular E10, you will need to add an octane booster, available at any auto store, or Wal-Mart.

So how do you remove the ethanol from E10? It's quite simple, actually - just add water! Remember, ethanol binds strongly to water. All you need to do is add some water to the gasoline, agitate to make sure it mixes well, then let it sit for a few minutes. The water will bond with the ethanol, and it will phase-separate out, falling to the bottom of the container.

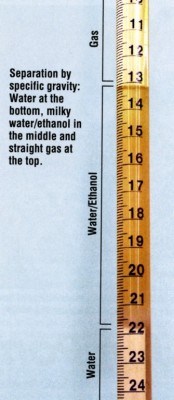

How much water do you add? Well you can't add too much. If you don't add enough, then it won't remove all of the E10, and what E10 does bond with the water, will separate to the bottom of your container. If you add too much, the available ethanol will bond to the water, and the remaining water will separate to the bottom. You'll then have three layers: gasoline on top, ethanol/water in the middle, and water on the bottom:

Three phase separation

In Dave's article, he used a cheap plastic separatory funnel with a small valve at the bottom, along with a 500cc cylinder for measuring the fuel and a 25cc burette for measuring water:

Measuring instruments

Once filling his funnel with E10, adding water and letting it sit, the water/ethanol separated out, and could be drained using the valve:

Separatory funnel

So how much water do you add? It depends on a few things, including the actual concentration of ethanol (which will vary - it's seldom exactly 10%), and ambient temperature. Dave's testing shows that the optimal amount of water is 2% by volume of the E10. That's 2.56 oz per gallon, or 12.8 ounces for a five-gallon gas can. Remember that extra water will simply separate out, so two cups (16 ounces) of water in a five-gallon gas can is safe. You should use distilled water only, to avoid leaving behind any minerals or other additives that your engine may not like (does fluoride keep your carburetors clean?).

The biggest problem - in what sort of container do you perform this procedure? Dave suggested a five-gallon glass or PET plastic jugs, like those that are found at http://www.midwestsupplies.com - fitted with stopcocks and vent tubes.

My suggestion is a bit simpler: Buy a regular five-gallon gas can:

To the end of the spout, glue several inches of large, transparent PVC pipe:

At the end of the PVC pipe, fasten a valve with a compression fitting:

2-way-plastic-ball-valves-11605-2401007.jpg (11.56 KiB) Viewed 1542 times

Fill the can with E10, add two cups of distilled water, fasten the spout/pipe/valve, shake well, then turn the gas can upside down - fit it in a sawhorse or some other fixture so that the PVC pipe is pointing straight down. You want the absolute lowest point of the gas can to be the outlet for the spout, so that all of the heavier water and ethanol/water moves out the spout and then into the PVC tubing. Wait for the ethanol/water to separate out and drop down into the PVC (you'll see it), then open the valve slightly to drain out the ethanol/water. Once it's drained out, turn the gas can back upright - and you're done!

Ethanol Extraction Rig

So do you want to do this every time you fill up your bike? Probably not. But it's certainly doable for small batches of gasoline for use in small engines (lawn mowers, weed trimmers, any two-stroke engine), to put in your bike just before putting it away for the winter (or for storage of any length of time), or for putting into devices that sit for long periods of time without being run - like backup generators.

I must give credit where due. This is reposted from a Honda Goldwing (GASP!) site called goldwingdocs.com

Read more: http://goldwingdocs.com/forum/viewtopic ... z2DqI5mMWk