Here's the most informative link:

Find the Progressive Suspension Fork Springs - 25/35 Spring Rate (lbs/in) - 11-1119 at Dennis Kirk. Shop our complete selection of Dirt Bike Motorcycle parts and accessories including the Progressive Suspension Fork Springs - 25/35 Spring Rate (lbs/in) - 11-1119.

www.denniskirk.com

Progressive Suspension does have them, but does not list Norton as a make:

www.progressivesuspension.com

The Dennis Kirk site picture more closely depicts what my springs look like. As you can see, the windings are not that close at the end, just gradually tighter.

Thanks for providing those spring images. I was intrigued because I happen to have the next numerical neighbor to the 11-1119 (25/35 quoted rates), which is the 11-1120 progressive spring - a significantly heavier spring with quoted rates of 35/55 lb/in. I concur with your comment about the spring appearance looking softer rather than firmer. Below is an image of the 11-1120 next to a fixed rate spring.

Before I started playing with my front end project I incorrectly assumed that as these progressive springs were compressed they provided a continuum of increasing spring rate with compression, when in fact that is not the case. They are basically a bi-rate spring, i.e., the initial rate is the composite of the tight- and loose-wound ends being deforming simultaneously, up to the point that the tight-wound end goes solid (coil to coil contact), at which point any further deformation occurs in the loose-wound end which is the 2nd rate of the spring.

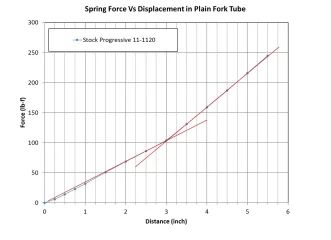

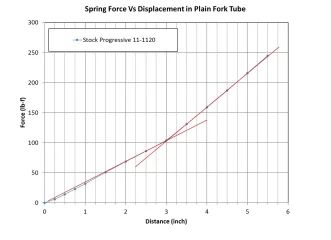

The plot below shows the deformation of the 11-1120 spring where I have added red lines over the blue data to emphasize the rate change - red line intersection shows clearly where the spring transitions from the 1st rate of about 35 lb/in to the 2nd rate of ~ 55 lb/in. Your spring would appear similarly, but the slopes would obviously be lower than shown on this plot (your 2nd rate would be the same as the 1st rate shown here), and of course we’d have no idea at what length your tight-wound end goes solid.

As Kommando noted, until the tight-wound end goes solid it is simply a fixed rate spring. In the alternative, for this specific installation (11-1120), if the combination of installed spring pre-load and sag-to-ride-height together add up to 3 inches of total compression, then the tight-wound end of the spring would be solid and this spring would simply be a fixed rate 55 lb/in spring.

As a final aside to progressive springs, and one that I suspect is of little to no interest to just about everyone here, is the rate of compressions springs in series (which these springs basically are), which I personally found fascinating. If you determine the individual rates of the 11-1120 tight- and loose-wound ends, using wire diameter, ID, and coil count, you come up with the tight-wound end having a rate of just under 98 lb/in and the loose-wound end having rate of just under 56 lb/in. Thus, with a 98 lb/in spring and 56 lb/in spring in series, how can you possibly come up with a 35 lb/in rate which is the factory quoted initial rate that occurs as you begin compressing the spring?

The formula for determining the rate of springs in series is the following. Spring rate = (Rate 1 * Rate 2) / (Rate 1 + Rate 2)

35.6 lb/in = (98 * 56)/(98 + 56)

So there is our initial 35 lb/in rate from 2 significantly stiffer springs in series.