If it is that maybe youd spot it with them at B D C , with your picthure McHine . the mark would only ? go to wrist pin hight .

a big no - no . Anyway .

Circlip Rant .

We All

INSPECT THE CIRCLIP GROOVES for no forign matter . Check the Circlip Size - relitive ( Bigger Than , unfitted ) the receptical .

So it IS under tension fitted . and we dont use cheap ones . AND the Hard edge Outward . ( Radiused edge to pin . )

With Circlip plier nose , after its in , it will usually rotate . UNTILL YOU ' SEAT ' it . So if you want em set relitive - arefull -

draging an end opens it . Pushing an end closes it . So - when where you want it ( put it tht way going in ! ) YOU THEN

" SEAT IT "

By pushing outward on both ends with circlip pliers that open outward when handles are closeing . ( prefeably - you get pliers both ways - opening & closeing types )

and ones that are a Correct Fit . Circlip dislodement is lack of attention to these . Little 4 m.m. wrist pins with self made . 016 inch wire circlips teach you precision , in these matters .

A load a vauugely relephat tripe . ( THESE are 'wire ' round section things . Like I wouldnt use in a Norton . but some motorcycle pistons DO USE Wire Circlips .

Many have commented about ST G4500 circlip failures, damaging the piston and cylinder. They have decided that breaking off the 90 degree tab on the clip is the solution. This should not be necessary. The primary cause of the failure appears to be among engines whereby the factory installed the clip with the tab horizontal, perpendicular to the piston travel, which is WRONG! It should be installed with the tab vertical, inline with the piston travel.

Apparently not all G4500 clips have been installed this way and why all engines do not experience this problem. The tab should be in the vertical position, either up or down, inline with the piston travel, as stated above.

I have found on my own NIB ST G4500, the clip was installed with the tab horizontal. The reason for the failures is primarily due to the flexing of the tab as the piston stops and reverses direction at TDC and BDC. The piston has significant insertia and each time it stops and changes direction, the circlip tab will flex. At the maximum recommended 8,000 rpm, that equals 16,000 times the tab will flex "per minute". It doesn't take long for the steel wire clip to fatigue and the tab breaking off, damaging your engine.

With the tab facing up or down in the "vertical" position, the flex is minimized, if not completely eliminated.

Remove your piston and check how the clip was inserted and if wrong, correct it. This just might save your engine!

you can see Tool Marks ! on this . ( naughty ) see above ! use yr stamped sheet type . Please .

talk about rough . WHO ' finished 'the ends . mustve been at smoko .

Yr S Tigre are hard bend ONE ARM . Not your open radius dual 'grabbers 'So tweezers to fit / remoove . !

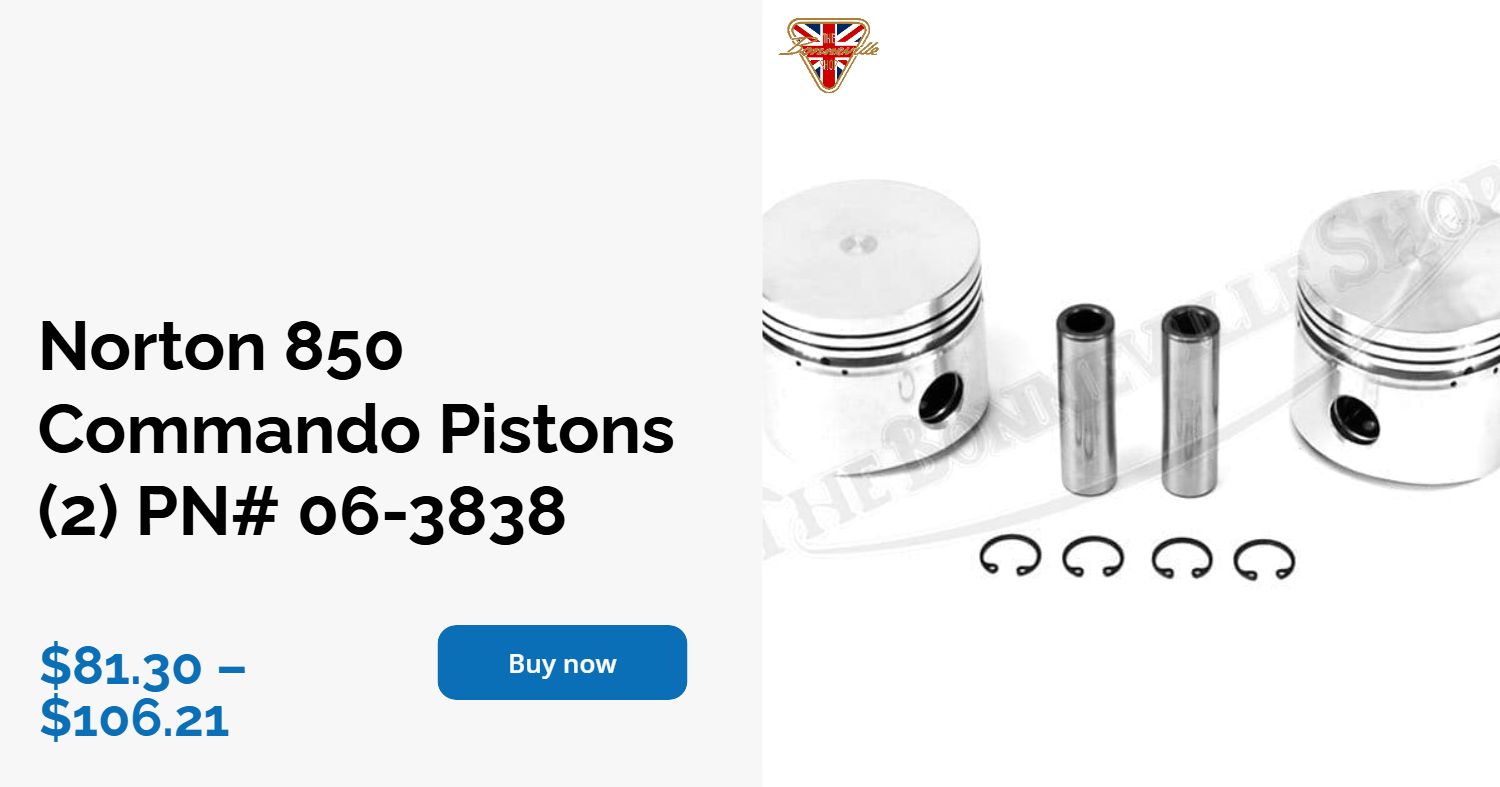

These re J E . ( Whatever ) "Wrist Pin Locks "

The LEFT one - obviously shown " back upward " as in the 'hard edge . Which goes OUTWARD . The underside off it should be rounded . And DEFINATELY DOES NOT go ' outward '

So it 'eases 'in . And 'sticks ' if pushed by the wristpin .

Just to over emphisise this .

this appears to be the INNER FACE of a B M W one ! the Hard Edge not being visable ? . Tho THAT is a female circlip .

A quality wrist pin one , CAREFULLY in your circlip liers , will twang / give SLIGHTLY . ( Dont abuse it )

Sat against a piston / wrist pin . OBVIOUSLY its bigger . but set oon opening , will 'give 'enough to DROP IN - Square - not fed one leg at a time ! . IF youve got good pliers . Not wobbly ones .

Elasticity and other tecnical terms .

Fitted , a light twist , and youll fell it 'seat 'and ' lock ' , installed . you Do Not "just drop it in '' it must be FITTED caefully & correctly . & not by four people simulteaneously useing a quater of their brain .

Good Light . Clean surfaces .

Ha Ha . little 4 m.m. OS Max . 40 FSR circlips FLY , you find them , in a few days . usually . But Big Oones can fly , too . Some People use a big plastic bag , removeing stuck ones . Unseating thems a lark .

THESE are little 5 m.m. ? fit , model aircraft ones .

probably 5 m.m. across - 16 thou wire . COOL CALM COLLECTED . Seady Hand , snake eyed & focused . To Fit . ( and remove ) With NO DISTRACTIONS .

They CAN be carefully fitted exactly . If you get n a comfortable clear sightline direct access position . First . Not a half harted throw em in , she'll be right .

A Precision Fit . One of the more critical . Spotlessly clean . inspected . groove . That Tang . some remove . But Id think its from wobbling / stressing it ,

usually bend em round round nose pliers with 'hard 'crease to leg . Not had one go . But consider wire second best to ' C ' clips . IF of a superior grade !