N0rt0nelectr@

VIP MEMBER

- Joined

- Sep 15, 2014

- Messages

- 1,192

Awhile back I needed to take the engine out of one of my Commando's but I still needed to move it around after I did that.

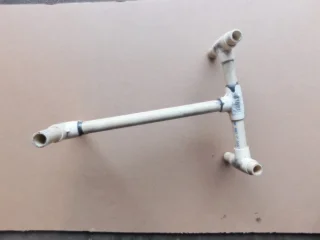

So I went to the local big box home improvement store and got some PVC fittings and pipe and built a tool to replace the crankcase. You may have seen them on line made out of steel. Being cheap I went with plastic.

Have you made a tool that makes life easier?

John in Texas

So I went to the local big box home improvement store and got some PVC fittings and pipe and built a tool to replace the crankcase. You may have seen them on line made out of steel. Being cheap I went with plastic.

Have you made a tool that makes life easier?

John in Texas