- Joined

- Oct 28, 2009

- Messages

- 1,326

I recently bought Hepolite pistons and rings for my Commando. I was told that the rings were made by Hastings, but I also have read that this isn't always the case.

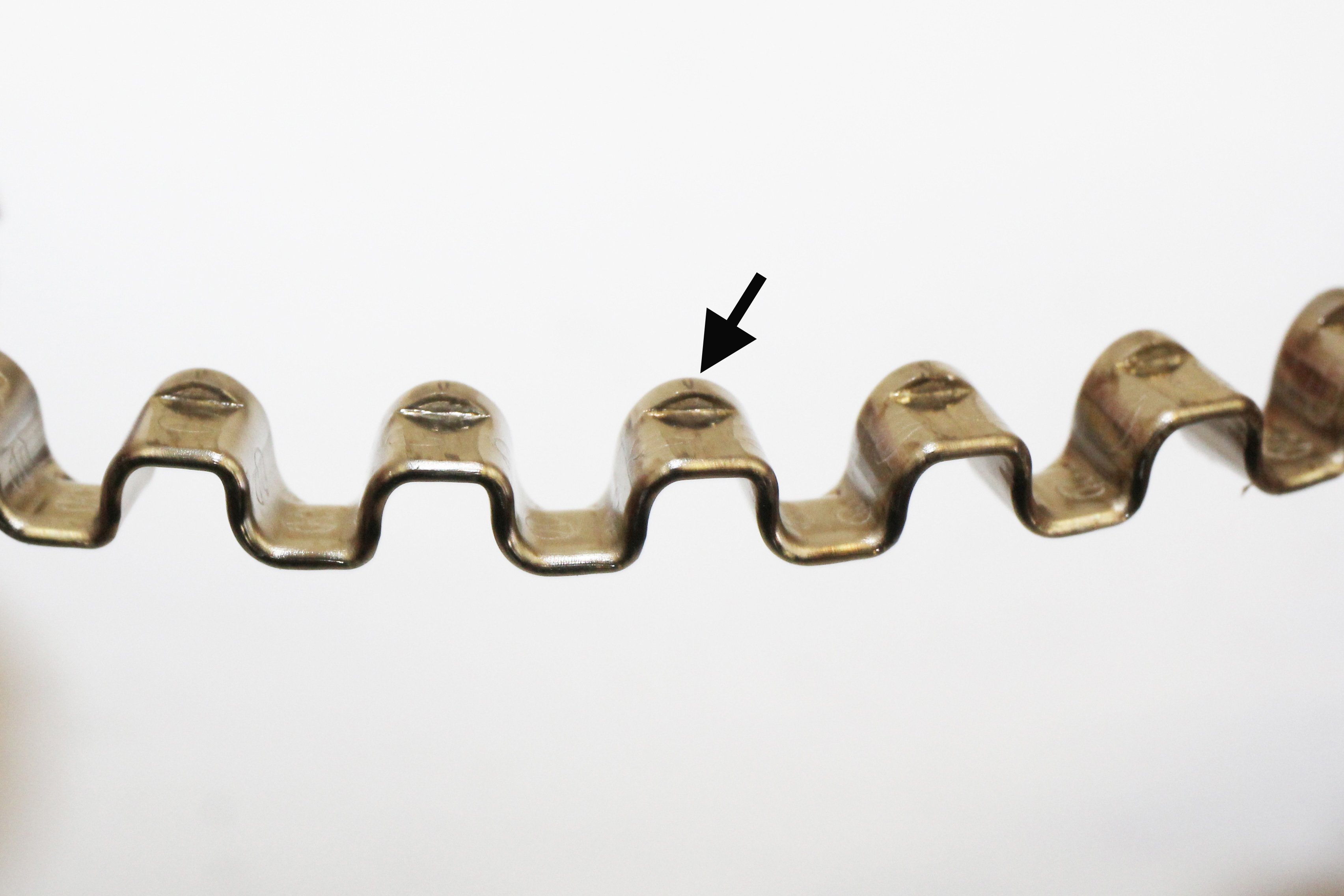

The oil control rings that came with the pistons seem wrong. They are a two piece style oil control ring, with a stiff inner spring that expands agains a cast iron outer ring. The amount of tension created by the inner spring is crazy. It is almost impossible to close the ring gap by hand. This is what they look like:

I can't see any practical way of compressing the oil ring enough to install it in the bore. Never mind how much drag the ring will place on the bore. I saw some earlier discussions similar to this but the expanding ring seemed to be a different style.

I am thinking of trimming the inner spring length to achieve a more reasonable expanding force.

Anybody else recently had this problem?

The oil control rings that came with the pistons seem wrong. They are a two piece style oil control ring, with a stiff inner spring that expands agains a cast iron outer ring. The amount of tension created by the inner spring is crazy. It is almost impossible to close the ring gap by hand. This is what they look like:

I can't see any practical way of compressing the oil ring enough to install it in the bore. Never mind how much drag the ring will place on the bore. I saw some earlier discussions similar to this but the expanding ring seemed to be a different style.

I am thinking of trimming the inner spring length to achieve a more reasonable expanding force.

Anybody else recently had this problem?

Last edited: