Thanks for visiting Access Norton

- Guest view limit reached

- Create a free account (more details)

- Already a member? Click here to login

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gasket question

- Thread starter MikeG

- Start date

- Joined

- Mar 22, 2021

- Messages

- 2,380

I've found copper coat useful on all sorts of surface seal jobs

www.onallcylinders.com

www.onallcylinders.com

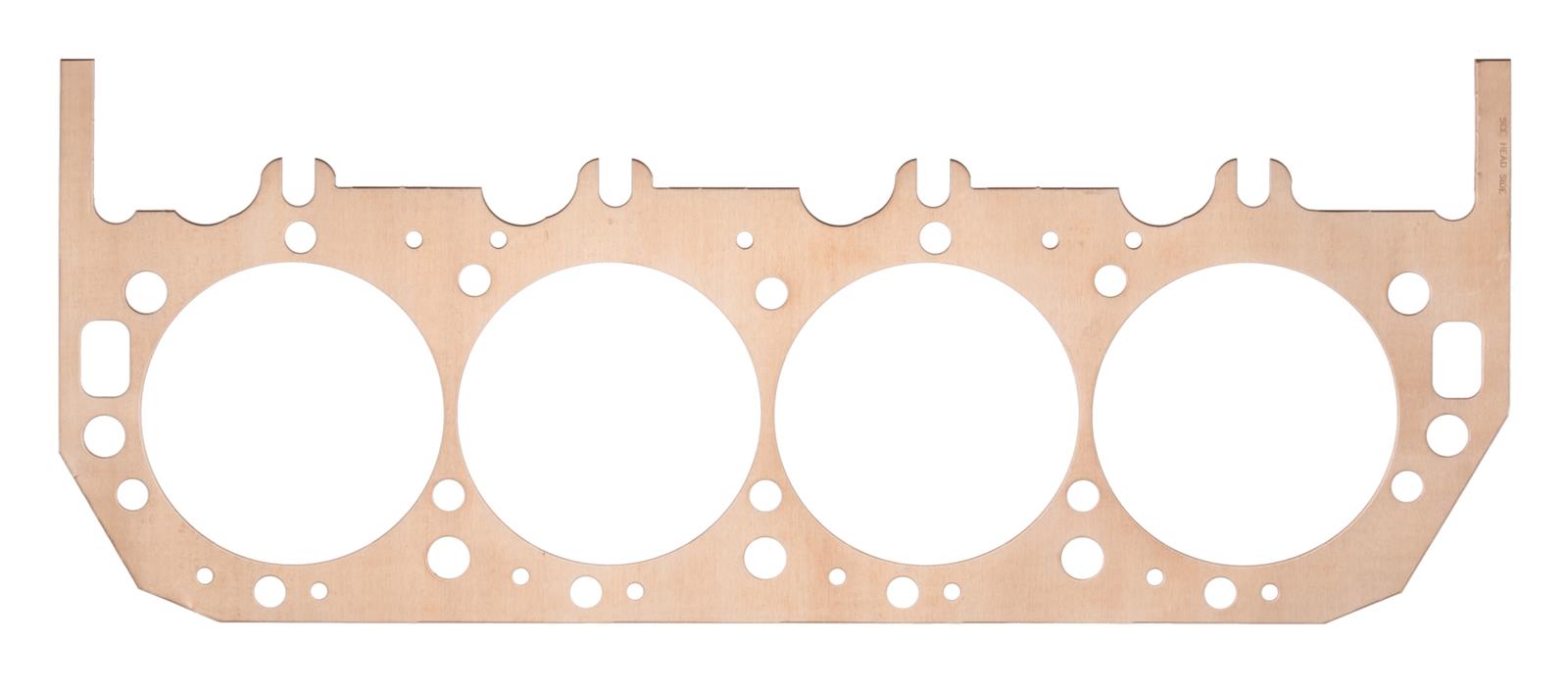

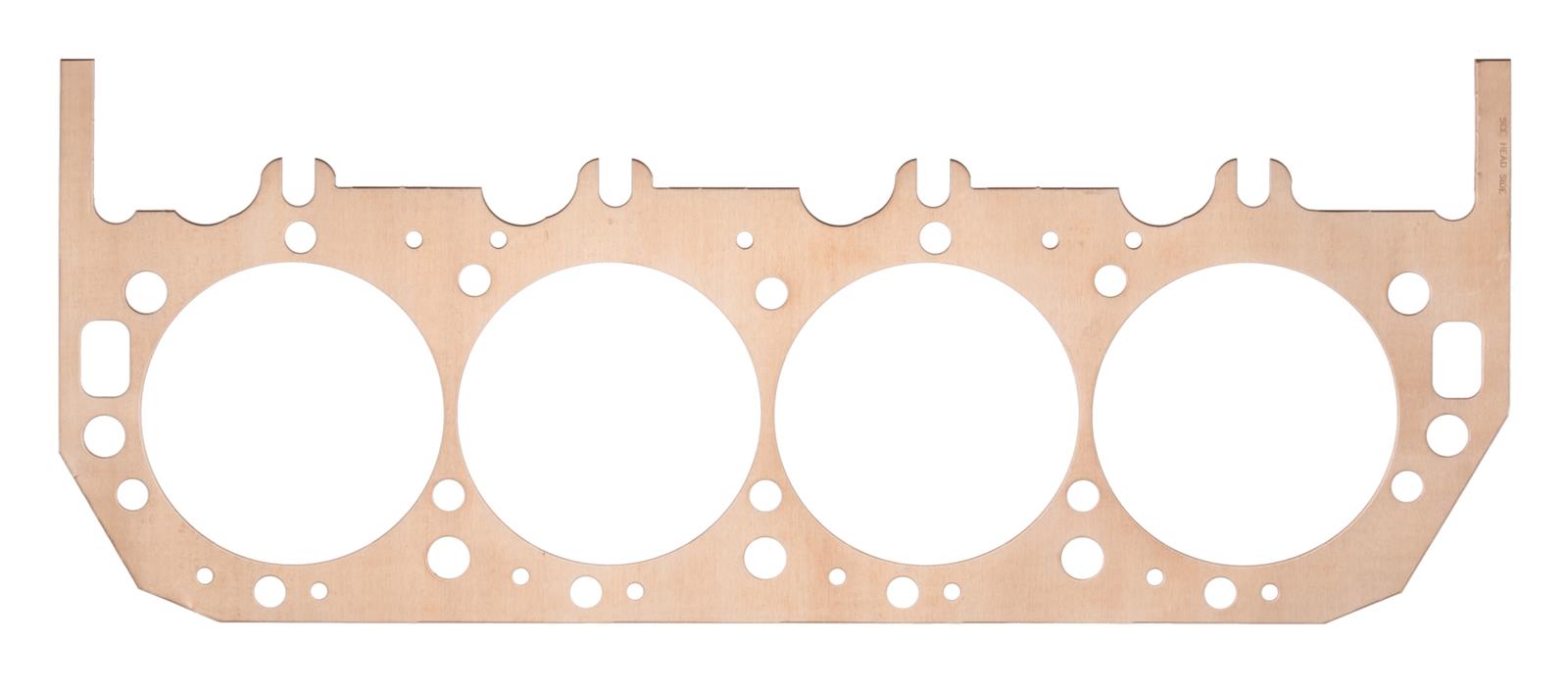

8 Tips for Properly Installing Copper Head Gaskets - OnAllCylinders

When stepping up to performance cylinder head gaskets, your first order of business will be choosing the gasket material best suited for your application. See our How to Choose the …

www.onallcylinders.com

www.onallcylinders.com

Last edited:

robs ss

VIP MEMBER

- Joined

- Aug 16, 2016

- Messages

- 4,366

If you search you will find work that Jim Schmidt (@jseng1 ) did on finding the best compound for copper head gaskets - the winner was Pliobond (didn't cook hard) plus using a loop of 0.005" copper wire around pushrod tunnels and rear oil drain, similar to what @ILLF8ED suggested but a little more specific.Should I use any kind of sealant on a new properly annealed copper gasket? For the record its on a BSA A10 rocker box, an area that I have never been able seal for very long. Lots of torsional stress the e due to the top engine mount.

Cheers

I think that the OP was trying to seal the rocker box to head joint with a copper gasket. The narrow mating faces would probably prevent the use of copper wire, but Pliobond on the gasket looks like a good suggestion.If you search you will find work that Jim Schmidt (@jseng1 ) did on finding the best compound for copper head gaskets - the winner was Pliobond (didn't cook hard) plus using a loop of 0.005" copper wire around pushrod tunnels and rear oil drain, similar to what @ILLF8ED suggested but a little more specific.

Cheers

robs ss

VIP MEMBER

- Joined

- Aug 16, 2016

- Messages

- 4,366

Sorry - I thought head gasket.I think that the OP was trying to seal the rocker box to head joint with a copper gasket. The narrow mating faces would probably prevent the use of copper wire, but Pliobond on the gasket looks like a good suggestion.

- Joined

- May 31, 2012

- Messages

- 1,510

I want to re-engineer the upper mount to incorporate something like a shock absorber bushing. Sealing flanges are far too thin for any type of pin.Mike, is there any place where we can add either dowel pins, or taper pins? That would take away the shaking-like-a-whore-in-church action of the head steady on the box.

concours

VIP MEMBER

- Joined

- Dec 29, 2011

- Messages

- 10,401

I would council strongly against that. Much knowledge gleened from a Beezer chopper custom head steady evolution.I want to re-engineer the upper mount to incorporate something like a shock absorber bushing. Sealing flanges are far too thin for any type of pin.

JMWO

baz

VIP MEMBER

- Joined

- May 26, 2010

- Messages

- 8,654

Where is your oil leak? I have been trying to stop a rocker box Leak on my A10 since I built it in around 1986 !!!!

Mine leaks at left side exhaust valve area of the box

Drives me mad ,I hate oil leaks and I've tried allsorts to stop it

It currently has an SRM Composit gasket and that has made it a bit better

I have tried a rocker cover breather etc etc

Mine leaks at left side exhaust valve area of the box

Drives me mad ,I hate oil leaks and I've tried allsorts to stop it

It currently has an SRM Composit gasket and that has made it a bit better

I have tried a rocker cover breather etc etc

- Joined

- Mar 22, 2021

- Messages

- 2,380

I had a quick search around for composition gaskets for this post and came up will nil...Where is your oil leak? I have been trying to stop a rocker box Leak on my A10 since I built it in around 1986 !!!!

Mine leaks at left side exhaust valve area of the box

Drives me mad ,I hate oil leaks and I've tried allsorts to stop it

It currently has an SRM Composit gasket and that has made it a bit better

I have tried a rocker cover breather etc etc

A friend of mine used anneal the copper gasket ..then thinly evenly coat it in a hi temp silicone and once it was full cured fit and torque it done as usual...it actually worked...for how long I'm not sure..but it was certainly oil tight a few months after he did the job...actually he was a ex Army Engineer ....

baz

VIP MEMBER

- Joined

- May 26, 2010

- Messages

- 8,654

Generally the rocker box base gaskets available are rubbish and don't fit wellI had a quick search around for composition gaskets for this post and came up will nil...

A friend of mine used anneal the copper gasket ..then thinly evenly coat it in a hi temp silicone and once it was full cured fit and torque it done as usual...it actually worked...for how long I'm not sure..but it was certainly oil tight a few months after he did the job...actually he was a ex Army Engineer ....

I've not tried the copper ones as yet

But may do in the near future

- Joined

- Mar 22, 2021

- Messages

- 2,380

Oh so it needs some glueGenerally the rocker box base gaskets available are rubbish and don't fit well

I've not tried the copper ones as yet

But may do in the near future

Sorry I was stuck on head gaskets..lol

My Army mate had a 920 and had the weep issue from the front of the head

Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 22,887

Yes probably, but also the design (as on a Triumph) means the valve springs are acting against the joint too.Fretting of gasket caused by the top motor mount working on the joint?

If you think about the pressure on those springs, and the amount of reciprocal movement at decent rpm, there’s potential for a lot of stress and fretting.

That’s why copper gaskets are good in this application.

But you need to be careful, I fitted some to a Triumph once, the pushrod holes weren’t quite right and the copper rubbed on the pushrod, it made such a horrid noise, like it was haunted / possessed

Similar threads

- Replies

- 22

- Views

- 1,805

- Replies

- 55

- Views

- 4,848

- Replies

- 24

- Views

- 2,248