Tornado

VIP MEMBER

- Joined

- Dec 5, 2017

- Messages

- 5,111

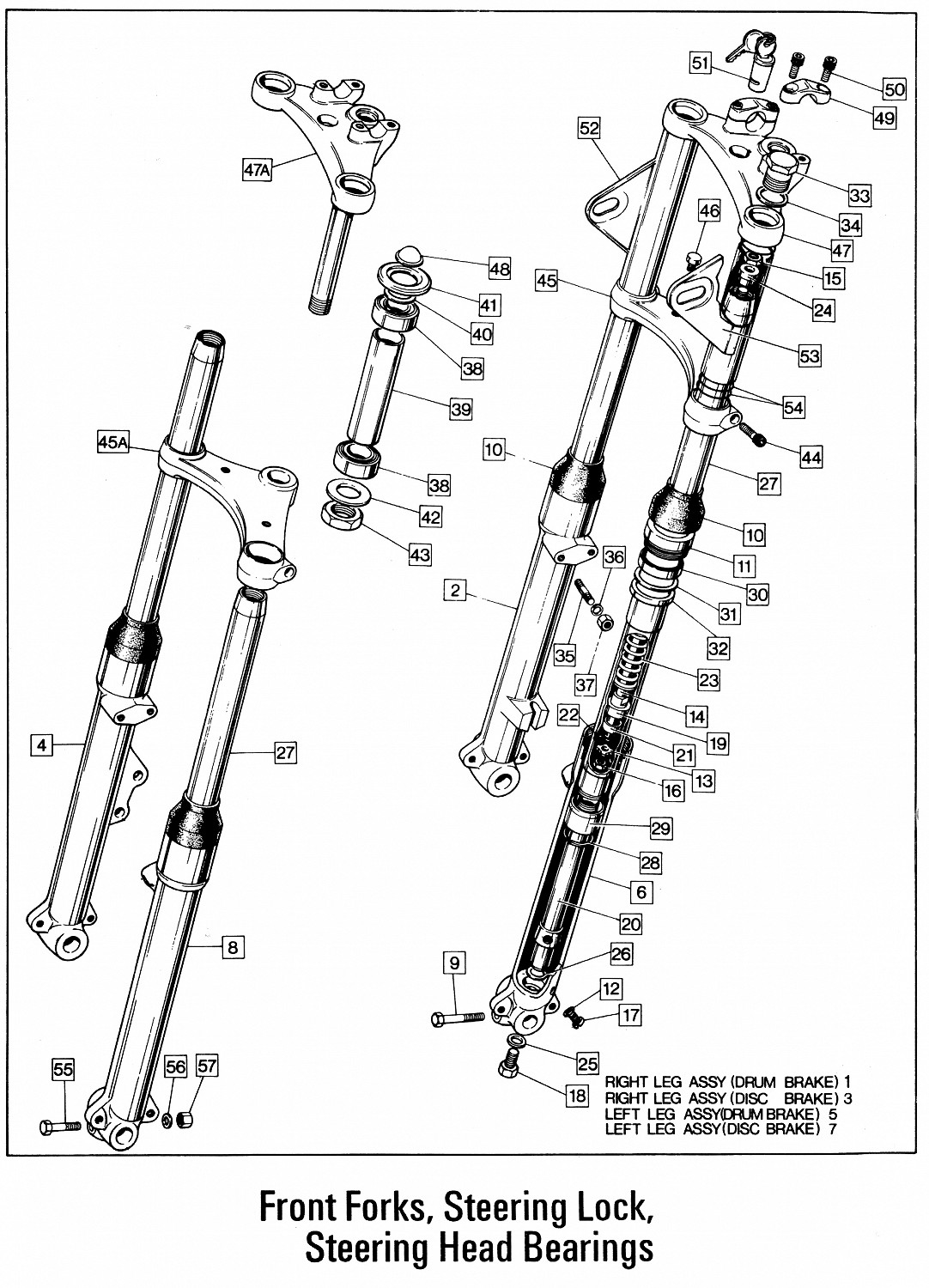

Drained fork oil, dropped front wheel so I could R&R the bolt into the damper tube and fit a dowty washer to solve oil weep issue.

Taking the top cap off to re-fill, found there was no damper rod threaded into cap, spring with thick spacer washer just sitting there. Lifted spring out to see rod way down deep with the nut sort of half balanced on end of rod. Managed to fetch out the nut using a strong magnet pickup tool, then got the rod up with same.

No wonder the front end was clunking a bit on hard bumps!

Taking other side top cap off, found once again nothing attached to it, this time the rod still had thr nut in place holding spring etc.

I cannot believe I didn't put this together correctly when rebuilding them two odd years ago. Then I recalled the shop that had taken bike down to bare frame also fit new headstock bearings etc, so that should have meant at least removing the top caps. They must not have secured the rods into caps on re-assembly.

Caps now don't want to thread on rod ends and rescued nut will not thread on the rod. Will try running a tap into caps and die on the rods.

Taking the top cap off to re-fill, found there was no damper rod threaded into cap, spring with thick spacer washer just sitting there. Lifted spring out to see rod way down deep with the nut sort of half balanced on end of rod. Managed to fetch out the nut using a strong magnet pickup tool, then got the rod up with same.

No wonder the front end was clunking a bit on hard bumps!

Taking other side top cap off, found once again nothing attached to it, this time the rod still had thr nut in place holding spring etc.

I cannot believe I didn't put this together correctly when rebuilding them two odd years ago. Then I recalled the shop that had taken bike down to bare frame also fit new headstock bearings etc, so that should have meant at least removing the top caps. They must not have secured the rods into caps on re-assembly.

Caps now don't want to thread on rod ends and rescued nut will not thread on the rod. Will try running a tap into caps and die on the rods.