texasSlick

VIP MEMBER

- Joined

- Jan 2, 2013

- Messages

- 4,180

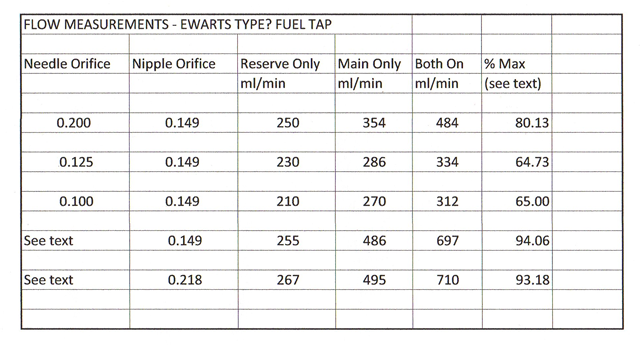

A thread on the Commando Forum piqued my interest to make some flow measurements on an Ewarts fuel tap as used on the Atlas.

The tap is pull for Main, and twist 90 deg. for Reserve.

I measured the fuel delivery to the float chamber of the Monobloc carburetor, which included flow resistance of the tap itself, plus the nipple (fitting that screws to outlet of fuel tap), 4.5 inches of 1/4 inch inside dia. flex tubing, banjo, filter screen, and finally needle orifice. This was done by removing the float chamber cover, allowing the float to rest on the bottom of the chamber, then collecting the fuel using a funnel and container over a one minute period. Time was measured with a precision stopclock, and fuel quantity measured with a 250 ml graduated cylinder.

Flow measurements were done for Reserve (only), Main (only), and both Reserve and Main on simultaneously, for each of three needle orifice sizes: 0.100, 0.125, and 0.200 inch dia. For these measurements, a nipple orifice of 0.149 inch dia. was used.

Flow measurements were also done for the fuel tap, nipple, and 4.5 inches of 1/4 inch dia tube only. The nipple and tube facilitated collection of fuel, and were thus included with the tap measurements. These measurements were done for Reserve, Main, and Both as described above, using nipple orifice sizes of 0.149, and 0.218 inch dia.

Results:

1) As one would expect, the larger the needle orifice, the greater the flow.

2) Reserve delivers from 70 to 80 % of the main flow when passing thru a needle and seat.

3) Reserve delivers about 53 % of the main flow when no other resistance (other than nipple and tube) is in the circuit.

4) Turning tap to Main plus Reserve, does not deliver combined total of flow. See % Max column on right. This figure is obtained by dividing the actual combined flow, by the sum of the Reserve and Main flows. For flow thru a needle, only 65% of the combined separate flow is obtained for the smaller needle orifice sizes, while the large needle delivers 80% of the combined flow. These results indicate the needle is the principal limiter of flow.

5) For flow straight out of the tap, thru the nipple and short tube, about 94 % of the combined total is achieved. The approx. 6% fall in flow is due to the internal geometry of the tap itself downstream of where the two streams come together inside the tap.

6) Increasing the nipple orifice does not significantly increase the flow. There is only about a 2% increase in flow from the 0.149 in. dia. nipple to the 0.218 in dia.(a 48% increase in diameter). This is in keeping with established fluid mechanics that a small reduction(increase) in the diameter of a tube does not significantly reduce(increase) flow, if the length of the tube having the reduced(increased) section is short (short is about 10 tube diameters).

The exit orifice of the Ewarts tap is 1/8 inch dia. It might be tempting to some to increase this bore, in an effort to get the free flow (no needle, seat, screen, etc) closer to 100% combined. This is not recommended, for item 6) explains only a small effect is achieved for a diameter change over a short distance. Moreover, increasing the diameter may result in gouging or tearing of the cork seal.

For reference, one US pint is 473 ml. We see that this type tap can deliver in free flow (without needle, etc) about 1.04 pints per minute (Main only) and about 1.5 pints per minute (Main plus Reserve), or all the fuel the carburetors can swallow.

Hope this helps.

Slick

The tap is pull for Main, and twist 90 deg. for Reserve.

I measured the fuel delivery to the float chamber of the Monobloc carburetor, which included flow resistance of the tap itself, plus the nipple (fitting that screws to outlet of fuel tap), 4.5 inches of 1/4 inch inside dia. flex tubing, banjo, filter screen, and finally needle orifice. This was done by removing the float chamber cover, allowing the float to rest on the bottom of the chamber, then collecting the fuel using a funnel and container over a one minute period. Time was measured with a precision stopclock, and fuel quantity measured with a 250 ml graduated cylinder.

Flow measurements were done for Reserve (only), Main (only), and both Reserve and Main on simultaneously, for each of three needle orifice sizes: 0.100, 0.125, and 0.200 inch dia. For these measurements, a nipple orifice of 0.149 inch dia. was used.

Flow measurements were also done for the fuel tap, nipple, and 4.5 inches of 1/4 inch dia tube only. The nipple and tube facilitated collection of fuel, and were thus included with the tap measurements. These measurements were done for Reserve, Main, and Both as described above, using nipple orifice sizes of 0.149, and 0.218 inch dia.

Results:

1) As one would expect, the larger the needle orifice, the greater the flow.

2) Reserve delivers from 70 to 80 % of the main flow when passing thru a needle and seat.

3) Reserve delivers about 53 % of the main flow when no other resistance (other than nipple and tube) is in the circuit.

4) Turning tap to Main plus Reserve, does not deliver combined total of flow. See % Max column on right. This figure is obtained by dividing the actual combined flow, by the sum of the Reserve and Main flows. For flow thru a needle, only 65% of the combined separate flow is obtained for the smaller needle orifice sizes, while the large needle delivers 80% of the combined flow. These results indicate the needle is the principal limiter of flow.

5) For flow straight out of the tap, thru the nipple and short tube, about 94 % of the combined total is achieved. The approx. 6% fall in flow is due to the internal geometry of the tap itself downstream of where the two streams come together inside the tap.

6) Increasing the nipple orifice does not significantly increase the flow. There is only about a 2% increase in flow from the 0.149 in. dia. nipple to the 0.218 in dia.(a 48% increase in diameter). This is in keeping with established fluid mechanics that a small reduction(increase) in the diameter of a tube does not significantly reduce(increase) flow, if the length of the tube having the reduced(increased) section is short (short is about 10 tube diameters).

The exit orifice of the Ewarts tap is 1/8 inch dia. It might be tempting to some to increase this bore, in an effort to get the free flow (no needle, seat, screen, etc) closer to 100% combined. This is not recommended, for item 6) explains only a small effect is achieved for a diameter change over a short distance. Moreover, increasing the diameter may result in gouging or tearing of the cork seal.

For reference, one US pint is 473 ml. We see that this type tap can deliver in free flow (without needle, etc) about 1.04 pints per minute (Main only) and about 1.5 pints per minute (Main plus Reserve), or all the fuel the carburetors can swallow.

Hope this helps.

Slick

Last edited: