napanorton

VIP MEMBER

- Joined

- Apr 19, 2009

- Messages

- 175

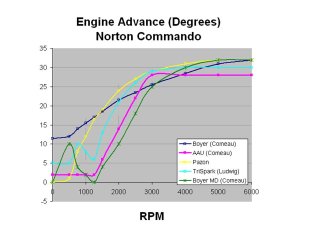

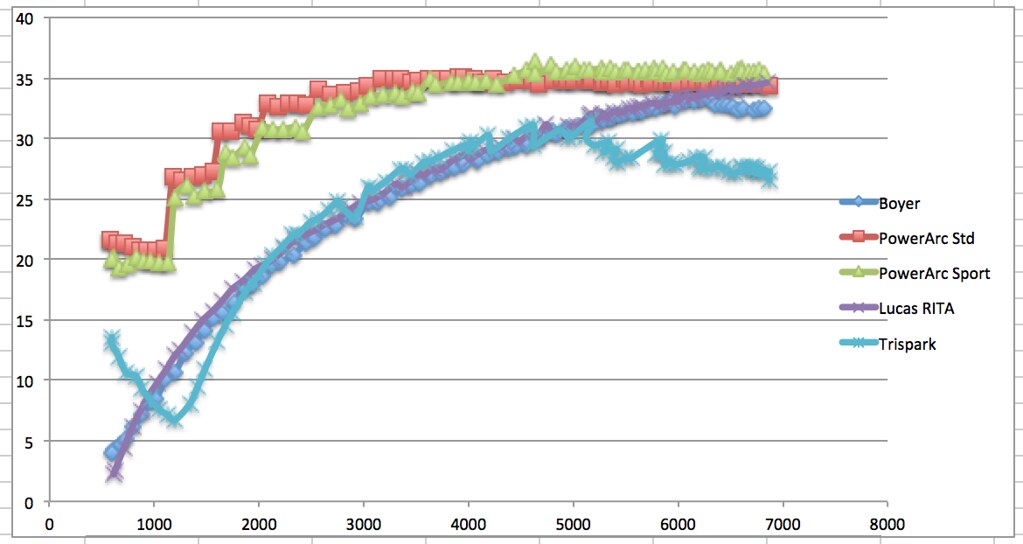

I realize a lot of this has been hashed out for years, so I'm not really adding much to the conversation. However it was a fun project and I learned a lot. I basically constructed a test harness to spin ignitions and measure the advance. I wrote up the results here: http://www.doovsprojects.com/projects/commando-ignitions. To cut to the chase, here's the summary graph

Note: the advance and rpms are crankshaft units. If you read my write up you'll see why the PowerArc advance is so different. Hopefully this info makes sense. Always open to any constructive feedback.

-- David

Note: the advance and rpms are crankshaft units. If you read my write up you'll see why the PowerArc advance is so different. Hopefully this info makes sense. Always open to any constructive feedback.

-- David