You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Disc manufacturer in Australia or NZ ?

- Thread starter GM 450

- Start date

- Joined

- Oct 20, 2021

- Messages

- 12

I’m silly enough the try and build a special (again)

Using a Honda NSR125 front end with Ducati single disc hub.

I have a new NSR disc but it doesn’t have enough offset and doesn’t fit the Ducati hub.

Easiest way I can see is to have a new disc centre made to suit the disc and hub.

The 2 places I know in Aus , one has a 2 year wait and the other seems to have closed.

Regards

Graeme

Using a Honda NSR125 front end with Ducati single disc hub.

I have a new NSR disc but it doesn’t have enough offset and doesn’t fit the Ducati hub.

Easiest way I can see is to have a new disc centre made to suit the disc and hub.

The 2 places I know in Aus , one has a 2 year wait and the other seems to have closed.

Regards

Graeme

Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 20,694

If you get no answers, HPS Performance in the U.K. do custom discs, you fill in their online form with all measurements and they get the disc made for you.

- Joined

- Oct 20, 2021

- Messages

- 12

Thanks Eddie and Kommando

I saw the place in the UK, that looks to be my only option.

Just being a tight arse I was trying to avoid the post costs. But I’ll contact them.

Looked at making an adapter but it will be ugly as it would be bigger than the hub to fit the NSR disc centre.

Regards

Graeme

I saw the place in the UK, that looks to be my only option.

Just being a tight arse I was trying to avoid the post costs. But I’ll contact them.

Looked at making an adapter but it will be ugly as it would be bigger than the hub to fit the NSR disc centre.

Regards

Graeme

- Joined

- Dec 3, 2012

- Messages

- 3,677

Those skills needed seem to be disappearing by the day as CNC takes over.

Why can a Ducati rotor not be used on the hub it will fit.

Either way some form of (fork) adapter would be needed unless a fork that makes it easier is used.

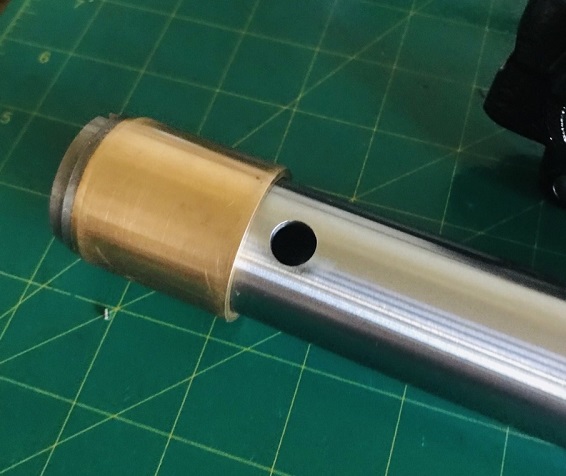

This was a replacement 4 hole floating carrier I cobbled up from a (new) floating Brembo rotor to replace the 6 hole for an RGV wheel along with a floating caliper, if you can not do it yourself it would cost a fortune for one off parts even if a source was found.

Why can a Ducati rotor not be used on the hub it will fit.

Either way some form of (fork) adapter would be needed unless a fork that makes it easier is used.

This was a replacement 4 hole floating carrier I cobbled up from a (new) floating Brembo rotor to replace the 6 hole for an RGV wheel along with a floating caliper, if you can not do it yourself it would cost a fortune for one off parts even if a source was found.

- Joined

- Oct 20, 2021

- Messages

- 12

I contacted Steve at F1E in NZ

Nice fellow but busy moving .

Timewarp,

Forks and triple clamps are from NSR125, wheel and hub from ‘74 yellow 450 Desmo. Ducati discs are 180mm dia. and has way too much offset.

I bought a new NSR 125 disc (315 dia) but needs extra 12mm offset to fit the Ducati 4 bolt hub. Also the disc centre hole is 130mm, the hub is 80mm.

Seems best to make. New disc centre to suit the hub and offset.

Also, the distance between the forks doesn’t allow for a double sided caliper (like bermbo 08) as they are too wide and hit the spokes, so the NSR Grimeca single side caliper fits.

(pm me with an email and I can send pics)

Graeme

Nice fellow but busy moving .

Timewarp,

Forks and triple clamps are from NSR125, wheel and hub from ‘74 yellow 450 Desmo. Ducati discs are 180mm dia. and has way too much offset.

I bought a new NSR 125 disc (315 dia) but needs extra 12mm offset to fit the Ducati 4 bolt hub. Also the disc centre hole is 130mm, the hub is 80mm.

Seems best to make. New disc centre to suit the hub and offset.

Also, the distance between the forks doesn’t allow for a double sided caliper (like bermbo 08) as they are too wide and hit the spokes, so the NSR Grimeca single side caliper fits.

(pm me with an email and I can send pics)

Graeme

Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 20,694

Strewth, you’re juggling a few balls in the air there Greame !

- Joined

- Dec 3, 2012

- Messages

- 3,677

That was probably 280 mm for the Ducati rotor.

Maybe there is another rotor that could be used and Brembo dual outer piston calipers are on a few bikes now for spoke clearence.

Anything will fit if the physical room is there somewhere.

DR780.

Commando.

I was told a while back there was no way Showa cartridges could be fit to 47 year old welded construction steel fork sliders.

Sounds like a good project you have there but a different hub would make it easier perhaps.

Maybe there is another rotor that could be used and Brembo dual outer piston calipers are on a few bikes now for spoke clearence.

Anything will fit if the physical room is there somewhere.

DR780.

Commando.

I was told a while back there was no way Showa cartridges could be fit to 47 year old welded construction steel fork sliders.

Sounds like a good project you have there but a different hub would make it easier perhaps.

- Joined

- May 7, 2005

- Messages

- 6,829

I solved this conundrum by changing the Showa outer tube to thin wall steel from thick wall aluminium and reducing the inner valves to 19mm. But I could not dial out the hi speed fork travel compression damping being too high, even with the thin wall tube the oil in the outer cavity does not move fast enough to allow the open shims full flow to take effect. So sadly a dead end unless the fork leg tube diameter can be increased.I was told a while back there was no way Showa cartridges could be fit to 47 year old welded construction steel fork sliders.

My last experiment works, racetech goldseal emulator valve clones on rods with one upside down to give rebound damping. X ring on OD running inside the stanchion to force the oil to take the route through the valve, as the valve is static inside the stanchion the X ring cannot wear out on the rough ID.

- Joined

- Dec 3, 2012

- Messages

- 3,677

I solved this conundrum by changing the Showa outer tube to thin wall steel from thick wall aluminium and reducing the inner valves to 19mm. But I could not dial out the hi speed fork travel compression damping being too high, even with the thin wall tube the oil in the outer cavity does not move fast enough to allow the open shims full flow to take effect. So sadly a dead end unless the fork leg tube diameter can be increased.

My last experiment works, racetech goldseal emulator valve clones on rods with one upside down to give rebound damping. X ring on OD running inside the stanchion to force the oil to take the route through the valve, as the valve is static inside the stanchion the X ring cannot wear out on the rough ID.

I meant more along the lines of it was not a bolt up.

All I did besides shortening the cartridges was machine the fork bottoms off, machine the axle blocks to take 8 mm cap screws and the cartridges then jig weld (ER70 root with rotator wire fill and cap) them back together.

There were other modifications but the stanchion ID does not seem to be a flow restriction to date.

I had considered modifying both units to be adjustable including the compression but this will do for now using Wirth internal progressive springs for a Le Mans. (External springs discarded)

- Joined

- May 7, 2005

- Messages

- 6,829

Trouble locally is potholes and my house being down a 400m rough track so I get to see high fork speed a lot and the digressive damping was not working as it does on my Commando with Showa cartridges with larger internal diameter fork legs. Looking at modern forks and others back into the double damping forks from 65 onwards the common finding is the 200mm2 is the x sectional area needed to remove a restriction so the main device for damping works. So I drill all stanchions with 200mm2 of holes so the oil movement to and from the cavity between the upper and lower bushes. If there are other routes that restrict oil flow other than shim stacks or damping holes then this 200mm2 rule applies.the smooth bore stanchion ID does not seem to be a flow restriction to date.

- Joined

- Dec 3, 2012

- Messages

- 3,677

Trouble locally is potholes and my house being down a 400m rough track so I get to see high fork speed a lot and the digressive damping was not working as it does on my Commando with Showa cartridges with larger internal diameter fork legs. Looking at modern forks and others back into the double damping forks from 65 onwards the common finding is the 200mm2 is the x sectional area needed to remove a restriction so the main device for damping works. So I drill all stanchions with 200mm2 of holes so the oil movement to and from the cavity between the upper and lower bushes. If there are other routes that restrict oil flow other than shim stacks or damping holes then this 200mm2 rule applies.

The four 6 mm holes in the steel cartridge tube total around 113 mm2.

These are on my 1973 Moto Guzzi and the modern replacement stanchions have an ID a shade over 27 mm so should be OK but the bottom bronze bush threaded retainer is the restriction (Unlike the Commando's circlip, the Moto Guzzi springs tested as a firm push fit in an original Commando stanchion ID)

I bored that ID as far as sensibility allowed.

That 27 mm ID is probably close to the limit as far as restriction to the 22.5 mm OD steel cartridge tube.

I had wondered (for not long) if I could do this to the 1949 Sunbeam and 1957 TR6 but the slider ID is no doubt far to small as would be the stanchion ID so restrictive.

The emulator type is about it.

I did cut the bodies down 42 mm to allow the longer internal springs and to lower the oil level based on a shorter fork (To the VFR)

The stanchions had a single 3 mm hole and drill/reamed it to 6 mm, un pot hole tested to date.

Is the brake rotor done yet ?

Last edited:

- Joined

- May 7, 2005

- Messages

- 6,829

I think 120mm2 would be ok as long as you aren't scrambling.

Note the huge holes in the Commando stanchion so the cavity between the upper and lower bushes is free flowing until the top out oil stop comes into play (provided your bushes or your damper rods are long enough).

As well as Guzzi V50 V35 springs Ninja 250 springs are another option and more readily available.

Note the huge holes in the Commando stanchion so the cavity between the upper and lower bushes is free flowing until the top out oil stop comes into play (provided your bushes or your damper rods are long enough).

As well as Guzzi V50 V35 springs Ninja 250 springs are another option and more readily available.

- Joined

- Dec 3, 2012

- Messages

- 3,677

Bigger holes @ 10mm.

The forks seem to work OK so have moved on to the lazy Susan Africa Twin turntable.

The dudes at the aluminium outlet asked how I would get that home on a motorcycle, easy, battery drill and 8 mm bolt and nut, fix it to the pannier rack.

The forks seem to work OK so have moved on to the lazy Susan Africa Twin turntable.

The dudes at the aluminium outlet asked how I would get that home on a motorcycle, easy, battery drill and 8 mm bolt and nut, fix it to the pannier rack.

Last edited: