You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Diameter of Alternator

- Thread starter Kjell

- Start date

- Status

- Not open for further replies.

guest76

Guest

- Joined

- Nov 5, 2012

- Messages

- 1,034

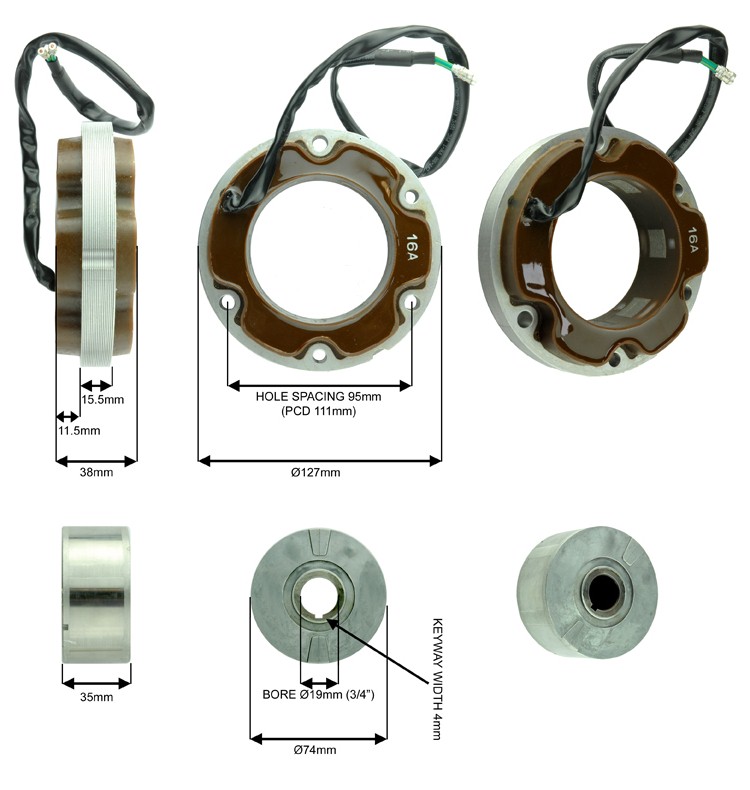

Yes, that’s correct - 74mm is the outside diameter of the rotor.

16 amp is a good fit for an electric start bike, but overkill for a standard bike.

Remember that all the extra power you are producing has got to find somewhere to go.

With electric start, you will spend most of your ride recharging a depleted battery, but with a standard bike, you are just getting your components unnecessarily hot.

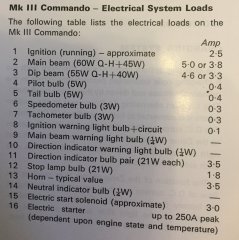

With everything switched on, a standard bike is drawing about 10 amps.

16 amp is a good fit for an electric start bike, but overkill for a standard bike.

Remember that all the extra power you are producing has got to find somewhere to go.

With electric start, you will spend most of your ride recharging a depleted battery, but with a standard bike, you are just getting your components unnecessarily hot.

With everything switched on, a standard bike is drawing about 10 amps.

- Joined

- May 7, 2005

- Messages

- 6,815

Read this

There are variations but they are the early 6V with different to 74mm OD and some thin ones for some Tiger Cubs.

There are variations but they are the early 6V with different to 74mm OD and some thin ones for some Tiger Cubs.

- Joined

- Jul 10, 2020

- Messages

- 88

Thanks a lot. I will stick with the kick and 10 ampsYes, that’s correct - 74mm is the outside diameter of the rotor.

16 amp is a good fit for an electric start bike, but overkill for a standard bike.

Remember that all the extra power you are producing has got to find somewhere to go.

With electric start, you will spend most of your ride recharging a depleted battery, but with a standard bike, you are just getting your components unnecessarily hot.

With everything switched on, a standard bike is drawing about 10 amps.

View attachment 17568

- Joined

- Jul 10, 2020

- Messages

- 88

Lots of good info indeed. Exactly what I was looking for. Thanks!!Read this

There are variations but they are the early 6V with different to 74mm OD and some thin ones for some Tiger Cubs.

- Joined

- May 30, 2019

- Messages

- 76

If you are/were considering replacing the stator you may want to consider replacing with a 3 Phase alternator. Direct replacement for stock and will provide increased charge at low RPM. It will require revisions to rectification/regulation – but Podtronic and other units that replace bridge rectifier and Zener diode are readily available and relatively inexpensive.

I did dimensional comparison with the original single-phase Lucas rotor and stator in my 1974 Commando Roadster and they were very close. Installation was plug-and-play and I achieved the .008” to .010” rotor to stator clearance with little effort.

Just a suggestion as you have it apart and it’s a good time to do.

I did dimensional comparison with the original single-phase Lucas rotor and stator in my 1974 Commando Roadster and they were very close. Installation was plug-and-play and I achieved the .008” to .010” rotor to stator clearance with little effort.

Just a suggestion as you have it apart and it’s a good time to do.

SteveA

VIP MEMBER

- Joined

- Dec 20, 2011

- Messages

- 3,280

Read this

There are variations but they are the early 6V with different to 74mm OD and some thin ones for some Tiger Cubs.

And whilst you are on Paul Goff's site look at getting some LED bulbs to reduce your system loading a great deal...with much brighter lighting...and even less reason to do an alternator upgrade....

- Joined

- Jul 10, 2020

- Messages

- 88

Tha

That was my original plan but then I read somewhere ( in some forum I do no remember which one) that at least a couple of guys had bad experiences with the 3 phase high output stators.They were out of spech i.e didnt fit the 74 mm rotor very well. Any other experienced that here on the forum?+ 1 For upgrading to a 3 phase alternator a a podtronics rectifier/regulator

- Joined

- Jan 4, 2014

- Messages

- 612

E-start here, so upgrading to 3 phase was a no-brainer. I have a halogen headlamp that I can just leave on all the time.

With the LED lamps available now I don't see any reason to upgrade if your battery stays up to snuff. A good voltage monitor is worthwhile. Here's what I use:

http://www.sparkbright.co.uk/sparkright-eclipse-battery-voltage-monitor.php

With the LED lamps available now I don't see any reason to upgrade if your battery stays up to snuff. A good voltage monitor is worthwhile. Here's what I use:

http://www.sparkbright.co.uk/sparkright-eclipse-battery-voltage-monitor.php

guest76

Guest

- Joined

- Nov 5, 2012

- Messages

- 1,034

Single Phase

Three Phase

A single phase alternator will show a positive charge on a Commando at between 2,000 and 3,000rpm

The three phase alternator will show a positive charge on a Commando at engine idle.

Standard output alternators are a good fit for standard electrics.

High output alternators are a good fitted for bikes with electric starters, heated grips or heated clothing.

All the above stators are 74mm and are matched with the RM20 rotor.

The fit of these units has been discussed in this group several times.

Here is a link to a good thread including my observations about fit.

https://www.accessnorton.com/NortonCommando/what-is-the-best-alternator-rotor-available-today.29280/

- LU47205 RM21 10 amp

- LU47239 RM23 16 amp (High Output)

Three Phase

- LU47252 RM24 10.5 amp

- LU47244 RM24 14.5 amp (High Output)

A single phase alternator will show a positive charge on a Commando at between 2,000 and 3,000rpm

The three phase alternator will show a positive charge on a Commando at engine idle.

Standard output alternators are a good fit for standard electrics.

High output alternators are a good fitted for bikes with electric starters, heated grips or heated clothing.

All the above stators are 74mm and are matched with the RM20 rotor.

- LU54202299 RM20 stator

The fit of these units has been discussed in this group several times.

Here is a link to a good thread including my observations about fit.

https://www.accessnorton.com/NortonCommando/what-is-the-best-alternator-rotor-available-today.29280/

- Joined

- Jul 10, 2020

- Messages

- 88

Single Phase

These are suitable for use with standard rectifier and zener diode.

- LU47205 RM21 10 amp

- LU47239 RM23 16 amp (High Output)

Three Phase

These will require a combined regulator/rectifier to be fitted and an extra wire outside the factor harness.

- LU47252 RM24 10.5 amp

- LU47244 RM24 14.5 amp (High Output)

A single phase alternator will show a positive charge on a Commando at between 2,000 and 3,000rpm

The three phase alternator will show a positive charge on a Commando at engine idle.

Standard output alternators are a good fit for standard electrics.

High output alternators are a good fitted for bikes with electric starters, heated grips or heated clothing.

All the above stators are 74mm and are matched with the RM20 rotor.

- LU54202299 RM20 stator

The fit of these units has been discussed in this group several times.

Here is a link to a good thread including my observations about fit.

https://www.accessnorton.com/NortonCommando/what-is-the-best-alternator-rotor-available-today.29280/

Thanks alot. Good info indeed. Warm clothing is used as standard equipment here in Norway wherever we go!

- Joined

- May 30, 2019

- Messages

- 76

As I mentioned in my earlier posting, I had no issues replacing the single-phase stator with a new three phase stator. I did replace the original rotor with a new rotor of the same part number. While I currently have no way of measuring the field strength of the original permanent magnet rotor, I figured it would be worth the additional $$$ to replace it as it was 46 years old.

The three-phase stator as mentioned in someone else’s posting has three wires as opposed to two. One item to address is the factory strain relief did not lend itself to fitting thru the primary rear cover with the additional wire. I found a rubber tube with a flange that sealed nicely within the machined spot face on the inside of the rear primary cover. To further seal I filled the tube with the non-corrosive RTV (alcohol cure rather than acetic acid – so no potential issues with wire corrosion).

The one area of the installation that I did deviate from stock was the axial centering of the rotor relative to the stator. Dimensionally the axial centerlines of the rotor and stator are not aligned. As the permanent magnet poles on the rotor are pretty broad it probably doesn’t matter as the stator poles are pretty narrow and the flux density is for the most part concentrated in those areas. More out of being OCD I modified the stator stud spacers to allow mounting as far in as possible to get closer to axial alignment. Again – probably of little consequence – driven by my Engineering background.

Moreover, I would recommend the three-phase alternator route. With the original alternator I grew tired of plugging in my trickle charger after every evening ride.

The three-phase stator as mentioned in someone else’s posting has three wires as opposed to two. One item to address is the factory strain relief did not lend itself to fitting thru the primary rear cover with the additional wire. I found a rubber tube with a flange that sealed nicely within the machined spot face on the inside of the rear primary cover. To further seal I filled the tube with the non-corrosive RTV (alcohol cure rather than acetic acid – so no potential issues with wire corrosion).

The one area of the installation that I did deviate from stock was the axial centering of the rotor relative to the stator. Dimensionally the axial centerlines of the rotor and stator are not aligned. As the permanent magnet poles on the rotor are pretty broad it probably doesn’t matter as the stator poles are pretty narrow and the flux density is for the most part concentrated in those areas. More out of being OCD I modified the stator stud spacers to allow mounting as far in as possible to get closer to axial alignment. Again – probably of little consequence – driven by my Engineering background.

Moreover, I would recommend the three-phase alternator route. With the original alternator I grew tired of plugging in my trickle charger after every evening ride.

- Joined

- Jul 10, 2020

- Messages

- 88

Thanks a lot. While we are at the subject of stator spacers. One would think it was possible to use the spacers already in place? However I was watching a youtube video the other night were a person claimed they had to be machined down.As I mentioned in my earlier posting, I had no issues replacing the single-phase stator with a new three phase stator. I did replace the original rotor with a new rotor of the same part number. While I currently have no way of measuring the field strength of the original permanent magnet rotor, I figured it would be worth the additional $$$ to replace it as it was 46 years old.

The three-phase stator as mentioned in someone else’s posting has three wires as opposed to two. One item to address is the factory strain relief did not lend itself to fitting thru the primary rear cover with the additional wire. I found a rubber tube with a flange that sealed nicely within the machined spot face on the inside of the rear primary cover. To further seal I filled the tube with the non-corrosive RTV (alcohol cure rather than acetic acid – so no potential issues with wire corrosion).

The one area of the installation that I did deviate from stock was the axial centering of the rotor relative to the stator. Dimensionally the axial centerlines of the rotor and stator are not aligned. As the permanent magnet poles on the rotor are pretty broad it probably doesn’t matter as the stator poles are pretty narrow and the flux density is for the most part concentrated in those areas. More out of being OCD I modified the stator stud spacers to allow mounting as far in as possible to get closer to axial alignment. Again – probably of little consequence – driven by my Engineering background.

Moreover, I would recommend the three-phase alternator route. With the original alternator I grew tired of plugging in my trickle charger after every evening ride.

One would think they were of equal width all of them

- Joined

- May 30, 2019

- Messages

- 76

Kjell -

You can use the spacers as is. As I recall they are .50" in length - all three of them. The only reason I would reduce their length is to get the axial center of the stator and rotor into closer alignment - the benefit to AC Voltage output is questionable. Obviously the factory didn't think it was a problem. It has been a while but I believe I reduced the length to approximately .40". That allowed the stator to be mounted closer to the rotor centerline and not have the plastic molded overlay contact the stud pillars.

Again, the benefit to output is questionable at best - probably not worth the effort. And yes, no reason to not have all three spacers at he same length.

You can use the spacers as is. As I recall they are .50" in length - all three of them. The only reason I would reduce their length is to get the axial center of the stator and rotor into closer alignment - the benefit to AC Voltage output is questionable. Obviously the factory didn't think it was a problem. It has been a while but I believe I reduced the length to approximately .40". That allowed the stator to be mounted closer to the rotor centerline and not have the plastic molded overlay contact the stud pillars.

Again, the benefit to output is questionable at best - probably not worth the effort. And yes, no reason to not have all three spacers at he same length.

- Status

- Not open for further replies.