- Joined

- Nov 26, 2009

- Messages

- 3,281

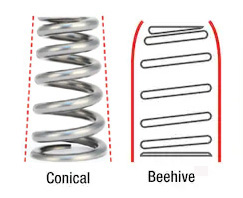

I’m posting this valve spring comparison because some confusing info about conical springs was posted on this forum years ago and it would be better to have it straight.

Here's a JS #2 Beehive spring and one of Comstocks “Conicals”. Can you see any difference or tell which is which?

In 2010 I started using beehive springs in Nortons. I have two different springs. Spring #1 is a little taller, more tapered and has a more linear rate. Spring #2 has slightly thicker wire, is a little shorter and has a higher spring rate. I provide spring #1 to most customers because of the more linear rate. I only send out the Spring #2 for extreme RPM short stroke racers because it can be installed at a higher pressure.

One day Jim Comstock called me and I sold him a set of my #1 springs at dealer discount.

Later on Comstock announced that he was introducing a “conical spring” and refereed to it with this link:

http://www.superchevy.com/how-to/en...-conical-valvesprings-story-behind-the-coils/

For a long time I wondered what this “conical” spring was all about. Just recently someone sent me a set of Comstock’s springs and I was surprised to see that they were not conical springs at all – but regular beehive springs. What's really surprising is that the JS #2 Beehive is identical to the Comstock spring. I had sent both of my #1 and #2 springs to him a couple years ago when he was making spintorn tests but he never posted anything about the #2 spring being identical to his.

When Comstock was asked “...about the actual functioning characteristics compared to the "beehive"? He said the conical has “Better ability to avoid resonant vibrations”. This is misleading because he is not using a conical and his spring is identical to the JS #2 spring. Comstock may have abandoned the “conical” spring he mentioned in favor of the beehive but he continued to call his springs “conical” on this forum.

Note the straight angle on the sides of the conical spring below. The photo shows a Chevy conical spring but the pressure is too high for a Norton and would cause premature cam wear.

The JS#2 spring is below left (same as Jim Comstock’s spring). The taller more tapered JS #1 beespring is below right.

You can get about 10 lbs more spring pressure with the stiffer #2 if you need it for a high RPM racer. Both require a different collet location than stock in order to avoid coilbind. In 2010 I made some deeper Titanium retainers on my CNC machine to avoid coil bind.

JS Titanium retainer below left, JC below right.

But the deeply located collets were a little difficult to remove and the deeper location required a thicker heavier lower section to prevent pull through (because the collets are only surrounded by the small diameter lower section). So instead I went with regular shaped TI retainers and a valve with a higher collet location near the valve tip to avoid the coil bind problem. This kept the Titanium retainer light, strong and gave a slightly lighter valve as well. By coincidence the abandoned JS deep collet retainers and the current Comstock retainers are just about the same and have the same collet location – even though we never saw each others deep retainers before we designed them.

Other differences are installation recommendation. I recommend the #1 spring with 90-95 lbs on the seat for street bikes because this is good for 8000RPM with the lightweight lifters and a stock performance cam. Comstock recommends 110 to 120 lbs (according to his specs). But the JS#2 and Comstock spring (the same) can both be shimmed up to about 150lbs on the seat for extreme RPM.

Here's a JS #2 Beehive spring and one of Comstocks “Conicals”. Can you see any difference or tell which is which?

In 2010 I started using beehive springs in Nortons. I have two different springs. Spring #1 is a little taller, more tapered and has a more linear rate. Spring #2 has slightly thicker wire, is a little shorter and has a higher spring rate. I provide spring #1 to most customers because of the more linear rate. I only send out the Spring #2 for extreme RPM short stroke racers because it can be installed at a higher pressure.

One day Jim Comstock called me and I sold him a set of my #1 springs at dealer discount.

Later on Comstock announced that he was introducing a “conical spring” and refereed to it with this link:

http://www.superchevy.com/how-to/en...-conical-valvesprings-story-behind-the-coils/

For a long time I wondered what this “conical” spring was all about. Just recently someone sent me a set of Comstock’s springs and I was surprised to see that they were not conical springs at all – but regular beehive springs. What's really surprising is that the JS #2 Beehive is identical to the Comstock spring. I had sent both of my #1 and #2 springs to him a couple years ago when he was making spintorn tests but he never posted anything about the #2 spring being identical to his.

When Comstock was asked “...about the actual functioning characteristics compared to the "beehive"? He said the conical has “Better ability to avoid resonant vibrations”. This is misleading because he is not using a conical and his spring is identical to the JS #2 spring. Comstock may have abandoned the “conical” spring he mentioned in favor of the beehive but he continued to call his springs “conical” on this forum.

Note the straight angle on the sides of the conical spring below. The photo shows a Chevy conical spring but the pressure is too high for a Norton and would cause premature cam wear.

The JS#2 spring is below left (same as Jim Comstock’s spring). The taller more tapered JS #1 beespring is below right.

You can get about 10 lbs more spring pressure with the stiffer #2 if you need it for a high RPM racer. Both require a different collet location than stock in order to avoid coilbind. In 2010 I made some deeper Titanium retainers on my CNC machine to avoid coil bind.

JS Titanium retainer below left, JC below right.

But the deeply located collets were a little difficult to remove and the deeper location required a thicker heavier lower section to prevent pull through (because the collets are only surrounded by the small diameter lower section). So instead I went with regular shaped TI retainers and a valve with a higher collet location near the valve tip to avoid the coil bind problem. This kept the Titanium retainer light, strong and gave a slightly lighter valve as well. By coincidence the abandoned JS deep collet retainers and the current Comstock retainers are just about the same and have the same collet location – even though we never saw each others deep retainers before we designed them.

Other differences are installation recommendation. I recommend the #1 spring with 90-95 lbs on the seat for street bikes because this is good for 8000RPM with the lightweight lifters and a stock performance cam. Comstock recommends 110 to 120 lbs (according to his specs). But the JS#2 and Comstock spring (the same) can both be shimmed up to about 150lbs on the seat for extreme RPM.

Last edited: