You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Classic British Spares Exhaust port repair

- Thread starter MikeG

- Start date

cliffa

VIP MEMBER

- Joined

- May 26, 2013

- Messages

- 3,804

Personally I would not go that route. The head will need to be machined anyway, so threaded inserts are the way to go in my opinion. Seager engineering in the U.K. would be my second choice after Jim, but somebody else on here might know of another good engineering shop in the U.S.

SteveA

VIP MEMBER

- Joined

- Dec 20, 2011

- Messages

- 3,281

For someone based in Europe, Seager would be my first choice. Complete with their stainless steel rose nuts!Personally I would not go that route. The head will need to be machined anyway, so threaded inserts are the way to go in my opinion. Seager engineering in the U.K. would be my second choice after Jim, but somebody else on here might know of another good engineering shop in the U.S.

lcrken

VIP MEMBER

- Joined

- Mar 15, 2009

- Messages

- 4,979

I would be a little nervous about using only a press fit. I've done similar repairs in the past by machining similar inserts, boring the head for a light press fit, and then welding them around the circumference. That was a fairly common way to repair them some years ago. But the last ones I had that needed repair were sent to Jim for his threaded bronze inserts. They are the best quality repair you can get.

That's not to say that the CBS ones won't work with just the press fit. It just doesn't seem like as reliable a procedure to me. It would be good to hear from someone who has actually used them.

Ken

Ken

That's not to say that the CBS ones won't work with just the press fit. It just doesn't seem like as reliable a procedure to me. It would be good to hear from someone who has actually used them.

Ken

Ken

lcrken

VIP MEMBER

- Joined

- Mar 15, 2009

- Messages

- 4,979

Never had a problem with them. The only issue with them was a cosmetic one. They no longer looked original.I agree Ken. I can envision that press fit sleeve sliding out right when you least expect it. If using a press fit aluminium sleeve I would at least add a few small tack welds around the perimeter.

Did your welded in sleeves hold up?

Glen

Ken

lcrken

VIP MEMBER

- Joined

- Mar 15, 2009

- Messages

- 4,979

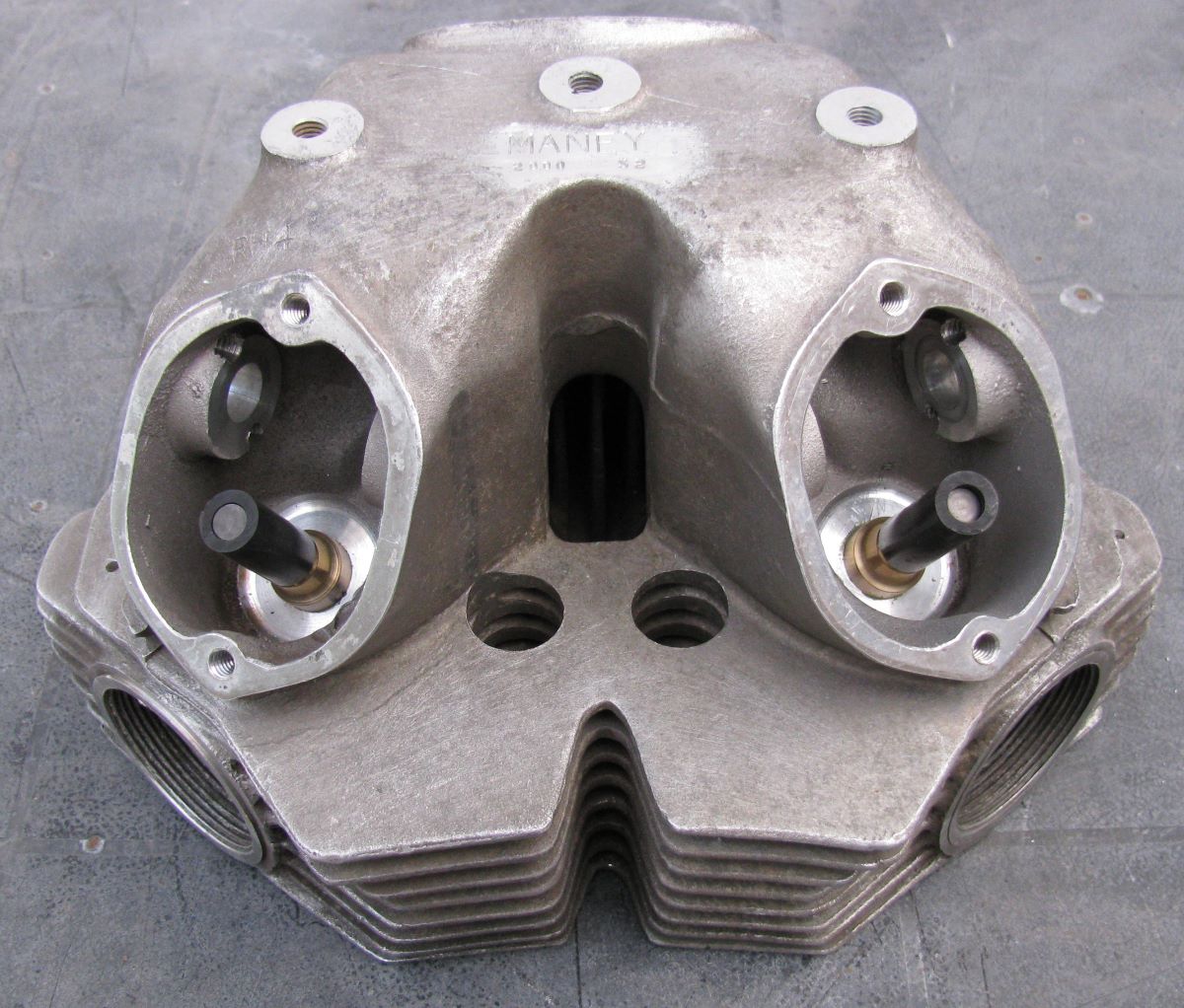

FWIW, Steve Maney used to do a repair with an aluminum insert, but it was threaded on the exterior. Steve bored out the original threads, thread milled new ones, and screwed the insert in. Similar to what Jim does, but I much prefer Jim's bronze inserts from a wear standpoint. This is picture one of his repaired heads.

Ken

Ken

- Joined

- Jul 15, 2007

- Messages

- 257

There's Dan Poitras in Ottawa Ontario listed in Facebook marketplace doing threaded bronze replacements. Don't know if this link works or not. Facebook funny sometimes -

www.facebook.com

www.facebook.com

Log into Facebook

Log into Facebook to start sharing and connecting with your friends, family, and people you know.

www.facebook.com

www.facebook.com

Tornado

VIP MEMBER

- Joined

- Dec 5, 2017

- Messages

- 4,532

He did my '74 850 two years ago. Doing fine after about 6500 miles riding since. These are similar/same alloy as used by Mr. Comstock I believe. Ran me about $400 Cdn for the pair and done within 10 days.There's Dan Poitras in Ottawa Ontario listed in Facebook marketplace doing threaded bronze replacements. Don't know if this link works or not. Facebook funny sometimes -

Log into Facebook

Log into Facebook to start sharing and connecting with your friends, family, and people you know.www.facebook.com

I had the chance to visit his place a year ago while in the region. He's a one man band, does this stuff & other machining work as a passion and not his main source of income.

Website with contact detail:

MikeG

VIP MEMBER

- Joined

- May 31, 2012

- Messages

- 1,242

If I have to use them I was considering a weld as well. The insert has a lip at the top that perhaps if I milled the head out a bit wider where the lip goes it will give me an area to run a bead of weld. My biggest concerne is the fact that it's aluminum rather than something less prone to stripped threads.

SteveA

VIP MEMBER

- Joined

- Dec 20, 2011

- Messages

- 3,281

The issue is that if the repair fails, then when you need the bronze insert the installer has twice the work to do, at your cost.If I have to use them I was considering a weld as well. The insert has a lip at the top that perhaps if I milled the head out a bit wider where the lip goes it will give me an area to run a bead of weld. My biggest concerne is the fact that it's aluminum rather than something less prone to stripped threads.

Pat Seager described dealing with one previously repaired as you describe recently on his Facebook feed.

- Joined

- Jun 30, 2012

- Messages

- 13,226

I suggest the best way to hold exhaust pipes to a cylinder head, is with slip joints and springs. Wnen the motor moves in relation to the exhaust pipes, threaded inserts which are clamped to the pipe must always wear the threads in the head. With my motor, I have threaded stups in the head and sleeves on the ends of the pipes. I use springs which stretch from the head to the pipes to pull the pipes towards the head. It is common practice on Japanese bikes. But with a Commando, it needs to be done before a problem develops. With damaged threads, it might be better to remove the threads completely and just use stubs without threads - and springs. Yamaha agents sell insulating washers which can go behind the stubs.

ashman

VIP MEMBER

- Joined

- Jul 11, 2010

- Messages

- 5,611

Problem with islastic motors they move and shake, don't seem to have a problem with my hard mount 850, I don't have any locking devices just the flange gasket and tighten the flange and header, with one mounting bolt for the muffler, has never come lose in 42+ years of riding it with this set up, but have worked on 2 Commandos with worn threads, one wasn't too bad and saved it with a thread file, the other was I thought was flogged right out and had a major bodge job of a repair done to it from the PO with welds and studs welded in place, some butcher got his hands on it, it was only the bottom part of the thread on one side that was stripped and could have been fixed easily as the flange still screwed in but a little lose.

So many butchers around who have no idea.

So many butchers around who have no idea.

- Joined

- Oct 28, 2014

- Messages

- 1,869

A major problem with the threaded insert whether welded or not is when the exhaust nut is tightened it can act as a puller and draw the insert out of the head. The threaded in type is the way to go. Comstock has the best repair.

franko

VIP MEMBER

- Joined

- Dec 29, 2013

- Messages

- 233

It was a while back in discussions about welded in inserts. Inserts with a land at the bottom for the pipe to seat against was thought to best for a weld in insert. As the pipe is tightened against the land in the insert itself, the pressure against the head is greatly reduced. The inserts without the land allow the pipe to push directly against the seat in the head. this exerts pressure to the insert. Drawing it out of the head.

I agree that Jims' method is best.

I agree that Jims' method is best.

- Joined

- Aug 19, 2021

- Messages

- 1,384

I think this is the same guy that did mine.There's Dan Poitras in Ottawa Ontario listed in Facebook marketplace doing threaded bronze replacements. Don't know if this link works or not. Facebook funny sometimes -

https://www.facebook [QUOTE="Dan195...OTE] .com/marketplace/item/1053297956029666/

Dzldanz

VIP MEMBER

- Joined

- Dec 23, 2018

- Messages

- 11

Thanks for the kind wordsHe did my '74 850 two years ago. Doing fine after about 6500 miles riding since. These are similar/same alloy as used by Mr. Comstock I believe. Ran me about $400 Cdn for the pair and done within 10 days.

I had the chance to visit his place a year ago while in the region. He's a one man band, does this stuff & other machining work as a passion and not his main source of income.

Website with contact detail:

Dzldanz

VIP MEMBER

- Joined

- Dec 23, 2018

- Messages

- 11

Thank YouI think this is the same guy that did mine.

- Joined

- Nov 26, 2009

- Messages

- 3,082

The EX threads are one of the most frequent Norton failures. Better to screw it in permanently with silicone sealer. Silicone braze a sleeve (so it fits the nut ID) and hook onto the pipe, Use a spring and be done with it forever. The OD of the nut fins have been turned down in the photo below.