- Joined

- Feb 12, 2020

- Messages

- 23

Hi Folks,

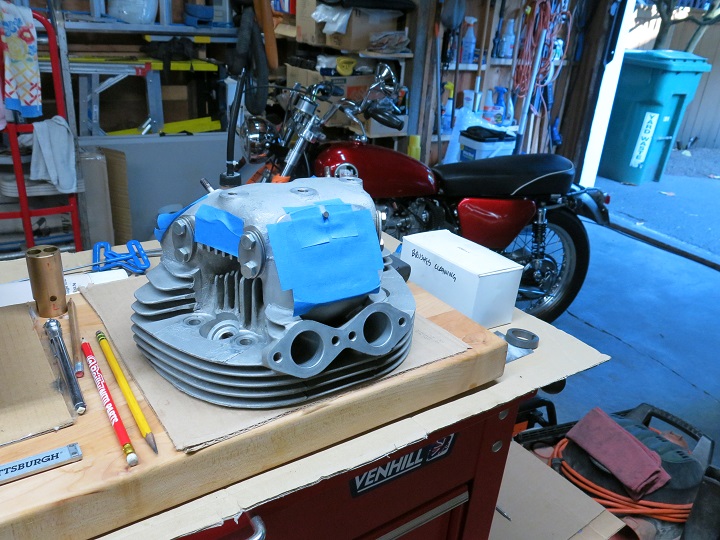

I'm nearing completion on a 1966 Atlas project and fired it up for the first time and noticed in all my excitement that oil was leaking from a bodged repair on the original rocker oil feed pipe. On closer inspection it looks like there has been a few repairs done already in the same place so not really wanting to play that game any more.

I do have a spare set braided oil rocker oil feed lines from a Commando and I'm wondering if anyone has tried using a set of Commando oil feed pipes on an Atlas. Any issues with doing this? I do have a spare set that I am able to use. I know that the Commando feeds from the side and Atlas from the top. TIA - Karl

I'm nearing completion on a 1966 Atlas project and fired it up for the first time and noticed in all my excitement that oil was leaking from a bodged repair on the original rocker oil feed pipe. On closer inspection it looks like there has been a few repairs done already in the same place so not really wanting to play that game any more.

I do have a spare set braided oil rocker oil feed lines from a Commando and I'm wondering if anyone has tried using a set of Commando oil feed pipes on an Atlas. Any issues with doing this? I do have a spare set that I am able to use. I know that the Commando feeds from the side and Atlas from the top. TIA - Karl