Atlas AMC Gearbox Sprocket nut

- Thread starter jms

- Start date

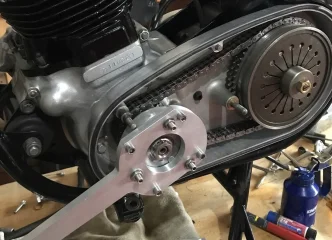

If you are trying to "lock the clutch" in order to tighten the rotor nut take an old driven clutch plate and a driving plate, bolt them together and add a handle. If the handle is long enough it will stop when it hits a foot peg, or you can rig up a clamp. This is the one I made for my Commando, but I have one for my Atlas, my Triumph and my BSA Victor

Attachments

jms

VIP MEMBER

- Joined

- Jul 26, 2005

- Messages

- 323

What a great Idea! ThanksIf you are trying to "lock the clutch" in order to tighten the rotor nut take an old driven clutch plate and a driving plate, bolt them together and add a handle. If the handle is long enough it will stop when it hits a foot peg, or you can rig up a clamp. This is the one I made for my Commando, but I have one for my Atlas, my Triumph and my BSA Victor

jms

VIP MEMBER

- Joined

- Jul 26, 2005

- Messages

- 323

Great work. What sort of a machine do you do the circular work on? A Bridgeport? Those used to be made in a few towns over from me meYes.

I have made service tools in general for decades.

This TL1000S tool is from 20 or so years ago.

View attachment 113902

- Joined

- Dec 3, 2012

- Messages

- 3,727

What a great Idea! Thanks

I have a clutch tool (Norvil sourced) to tighten the clutch nut but would never use it personally to tighten the rotor nut as that would put the 70ft/lbs of torque into the primary chain.

That was the reason I machined a split clamping collar that attached to the sprocket nut tool and then holds the rotor independently.

The sprocket nut tool came about the same way, no stress to the gearbox or any other part besides applying the 70ft/lbs torque to the sprocket nut.

I have seen posts with things jammed in the works etc but that is not something I would consider when I have the machine tools to make service tools (a simple ground and welded steel tool could be made also speaking as a Boilermaker/Welder by trade)

- Joined

- Dec 3, 2012

- Messages

- 3,727

Great work. What sort of a machine do you do the circular work on? A Bridgeport? Those used to be made in a few towns over from me.

The steel handled TL1000 clutch tool was made on my 1984 Rong Fu RF30 mill/drill purchased in 1985 and sold in 2020.

The Norton tool was made on a HM46 mill/drill which I converted to 4 axis Ditron DRO, power table feed and a homemade quill power feed.

I have used Bridgeport's over the years, but mill/drills are fine for home use.

Milled circles and curves are all done on a rotary table.

As far as the sprocket nut, on this website and the likes of FB, many just jam something against the sprocket tooth and frame which is Bogan A1+ to me unless there was no other option.

One option might be to get a steel round bar or RHS with a section of old drive chain welded to one end. That could be wrapped around the sprocket (with some form of securing so it did not slip)

It would do just what that shiny tool does and if the bar was long enough make the sprocket tightening independent so no stress to the gearbox not being jammed up against the frame etc.

What I learned starting around 1979 was show British bikes (for one) some mechanical empathy as the bodging started at the factory but did not need to continue once they left the showroom floor.

- Joined

- Jan 2, 2013

- Messages

- 4,256

If you are trying to "lock the clutch" in order to tighten the rotor nut take an old driven clutch plate and a driving plate, bolt them together and add a handle. If the handle is long enough it will stop when it hits a foot peg, or you can rig up a clamp. This is the one I made for my Commando, but I have one for my Atlas, my Triumph and my BSA Victor

I made a lock tool as drp describes, but took it further by welding a strap across the center, and in the center of that strap, welded a large nut. Then I use use a socket and long socket handle to apply the lock torque. Makes for more compact storage of the tool. See Reply #16: https://www.accessnorton.com/NortonCommando/tools-you-have-made-to-maintain-your-norton.32308/ for a picture.

The tool doubles as device to insert the cush rubbers in the AMC clutch center.

Slick

Last edited:

Similar threads

- Replies

- 10

- Views

- 1,110