You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

5 degrees advanced cam timing

- Thread starter jseng1

- Start date

- Status

- Not open for further replies.

- Joined

- Dec 3, 2009

- Messages

- 203

lcrken

VIP MEMBER

- Joined

- Mar 15, 2009

- Messages

- 4,982

The magazine says you can put the cam key in a vise, and knock it over with a chisel to get an offsest key. A more precise method, which I've used several times, is to start with a wider key, and file both sides to get the same sort of dogleg offset.

Ken

Ken

- Joined

- Jun 30, 2012

- Messages

- 13,231

I softened the cam sprocket by heating it on a piece of firebrick then broached two more keyways into it at random about 120 degrees apart. Because it is on a racer , I did not bother to reharden the sprocket. I never use timing marks - only the degree wheel and pointer on the crank to set up the cam timing. Find TDC by the soap bubble/broken spark plug method.

Brooking 850

VIP MEMBER

- Joined

- Oct 3, 2011

- Messages

- 1,609

Jim I am using a stepped key on my JS2 cam with standard distance between the cam and idler sprocket ie 9 pins between dots, with three teeth on from the standard timing dots between the crank pinion and idler.

No pics of the stepped key though.

Regards Mike

No pics of the stepped key though.

Regards Mike

SteveA

VIP MEMBER

- Joined

- Dec 20, 2011

- Messages

- 3,282

Brooking 850 said:Jim I am using a stepped key on my JS2 cam with standard distance between the cam and idler sprocket ie 9 pins between dots, with three teeth on from the standard timing dots between the crank pinion and idler.

No pics of the stepped key though.

Regards Mike

ummm...standard distance would be 10 pins!

- Joined

- Jan 10, 2005

- Messages

- 1,043

What was I saying! Of course 1 tooth cam = 40 degrees, 3 teeth crank = 45 degrees, net 5 degrees advance or retard depending on which way components are rotated opposite to each other. So picture is correct for 5 degrees advance on std, text is wrong. Apologies.Keith, eleven chain rollers between your sprocket marks would be one tooth clockwise on the cam and I agree with the three teeth on the crank gear but that is anticlockwise. Giving 5 degrees advance.

johnm

VIP MEMBER

- Joined

- Feb 26, 2008

- Messages

- 1,619

The Norton engine is constrained by having a single camshaft so when you advance the inlet you also advance the exhaust. So this masked the result a little.

But in theory, and many times in practice, advancing the inlet cam will improve mid range power without hurting the top end (say between 3500 and 5500 rpm) . The trade off is that below around 2000 to 3000 you may get a significant power loss.

For racing this can be extremely helpful.

AG Bell suggests if you advance the inlet you can sometimes restore any loss of top end by retarding the exhaust cam. Obviously with a Norton you cant do this without remachining the cam but on a Triumph twin it is possible. ( Having checked you are not going to cause the valves to collide during overlap )

)

I did this experiment on my 500 Dominator race bike more than ten years ago and got a good HP gain on the dyno between 4300 and 6200 (up to 4 bhp at some points). In my case the power remained unchanged above 6200 rpm) But the bike had no power whatsoever below 4000 so only good for racing.

(I experimented up to 13 deg advance using a vernier. )

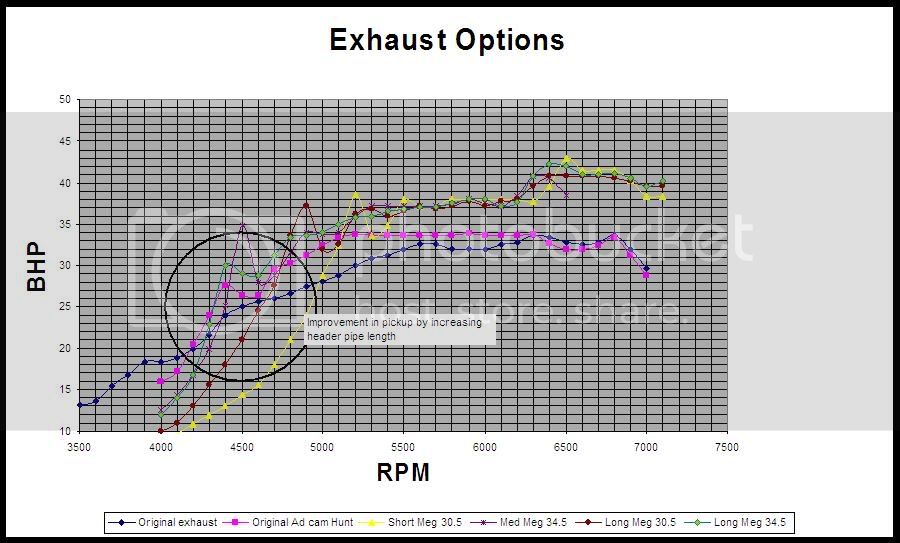

If you look at this plot the blue line is labeled original exhaust. Then compare with the pink line which is the same set up but with the cam advanced 13 deg. No other changes made. You can see the gains and losses. This is useful on a 500 race bike because power in this part of the curve gets you out of corners. This was very early in my tests and eventually I got the rear wheel dyno power over 51 bhp on petrol. These two runs were done with street style exhausts. The higher runs are with different megaphone and header pipe experiments so ignore them.

[/URL]

[/URL]

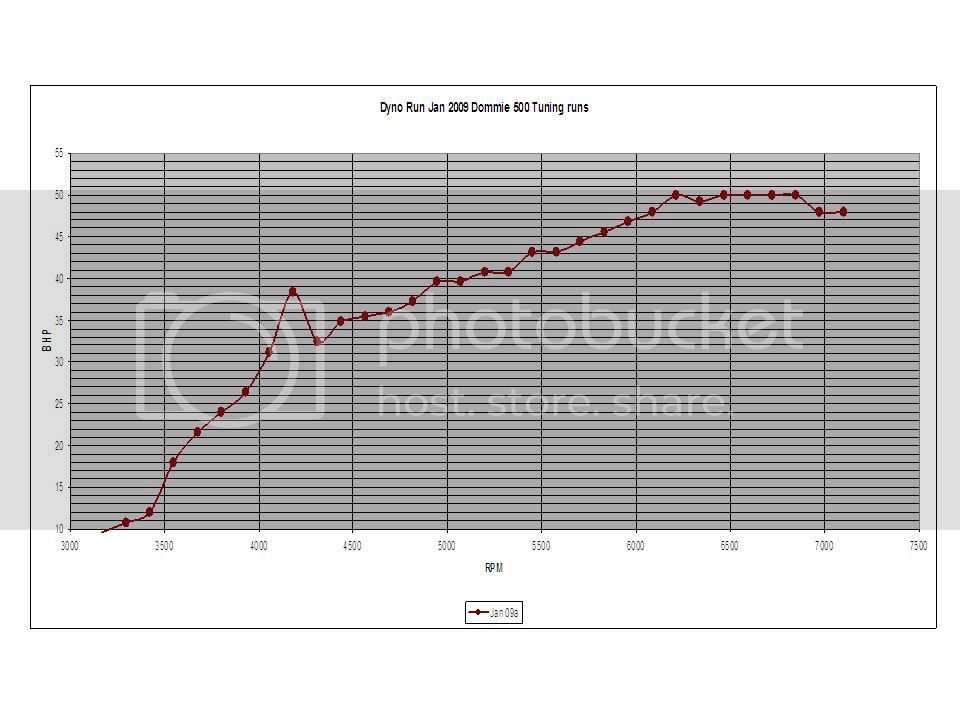

This is the final result with optimized cam timing, exhausts, inlet tuning , carbs, ignition timing etc

[/URL]

[/URL]

But in theory, and many times in practice, advancing the inlet cam will improve mid range power without hurting the top end (say between 3500 and 5500 rpm) . The trade off is that below around 2000 to 3000 you may get a significant power loss.

For racing this can be extremely helpful.

AG Bell suggests if you advance the inlet you can sometimes restore any loss of top end by retarding the exhaust cam. Obviously with a Norton you cant do this without remachining the cam but on a Triumph twin it is possible. ( Having checked you are not going to cause the valves to collide during overlap

I did this experiment on my 500 Dominator race bike more than ten years ago and got a good HP gain on the dyno between 4300 and 6200 (up to 4 bhp at some points). In my case the power remained unchanged above 6200 rpm) But the bike had no power whatsoever below 4000 so only good for racing.

(I experimented up to 13 deg advance using a vernier. )

If you look at this plot the blue line is labeled original exhaust. Then compare with the pink line which is the same set up but with the cam advanced 13 deg. No other changes made. You can see the gains and losses. This is useful on a 500 race bike because power in this part of the curve gets you out of corners. This was very early in my tests and eventually I got the rear wheel dyno power over 51 bhp on petrol. These two runs were done with street style exhausts. The higher runs are with different megaphone and header pipe experiments so ignore them.

This is the final result with optimized cam timing, exhausts, inlet tuning , carbs, ignition timing etc

- Joined

- Jul 24, 2006

- Messages

- 1,065

Jim, for a comprehensive list of advancing / retarding the cam see below.

To retard cam; Gear teeth @ 15* Sprocket teeth at 40*

-5 * - 3 teeth + 1 tooth

-10* + 2 teeth - 1 tooth

-15 * - 1 teeth std marks

-20* - 4 teeth + 1 tooth

To advance cam; Gear teeth @ 15* Sprocket teeth @ 40*

+5* +3 teeth - 1 tooth

+10* - 2 teeth + 1 tooth

+15* + 1 tooth std marks

+20* + 4 teeth - 1 tooth

I had written this with the correct number of + or - teeth spaced out under the headings and then went back and underlined the headings, and this has caused all of the info to go to the left of the margin and it won't space out. I hope it still makes sense.

To retard cam; Gear teeth @ 15* Sprocket teeth at 40*

-5 * - 3 teeth + 1 tooth

-10* + 2 teeth - 1 tooth

-15 * - 1 teeth std marks

-20* - 4 teeth + 1 tooth

To advance cam; Gear teeth @ 15* Sprocket teeth @ 40*

+5* +3 teeth - 1 tooth

+10* - 2 teeth + 1 tooth

+15* + 1 tooth std marks

+20* + 4 teeth - 1 tooth

I had written this with the correct number of + or - teeth spaced out under the headings and then went back and underlined the headings, and this has caused all of the info to go to the left of the margin and it won't space out. I hope it still makes sense.

- Joined

- Nov 26, 2009

- Messages

- 3,086

The point is to correct the cam timing when the keyway is not perfectly located. Or to make corrections when the chains, sprockets and gears are a little off. I'm not suggesting that the cam be advanced beyond its ideal efficiency. Although I find that Axtell's cams were advanced a degree or two past being a "straight up split". Note that the factory HD XR750 specs call for 6 deg intake advance. All my cams seem to run best with a couple degrees advance from 'a straight up split". What I'm putting together are instructions with pics after a customer called asking for something a little easier to understand. So I'm using the pics and illustrations shown here with the text below.

*************************************************************************************************************************************

Time the intake Lobe center at TDC to 102 degrees for JS stage 0 and stage 1 cams. 103 degrees for JS stage 2 & 3 cams (see cam timing instructions and compare the intake to exhaust valve lift at TDC – this is an easier way than finding lobe centers and it comes out the same). At the beginning of the intake stroke, the relationship of the intake lobe center location compared to the exhaust at TDC is what is important – the intake lobe center should be a degree or two less than the exhaust at TDC – this means the cam is advanced a couple degrees because the intake lobe center is closer to 0 degrees at TDC than the exhaust.

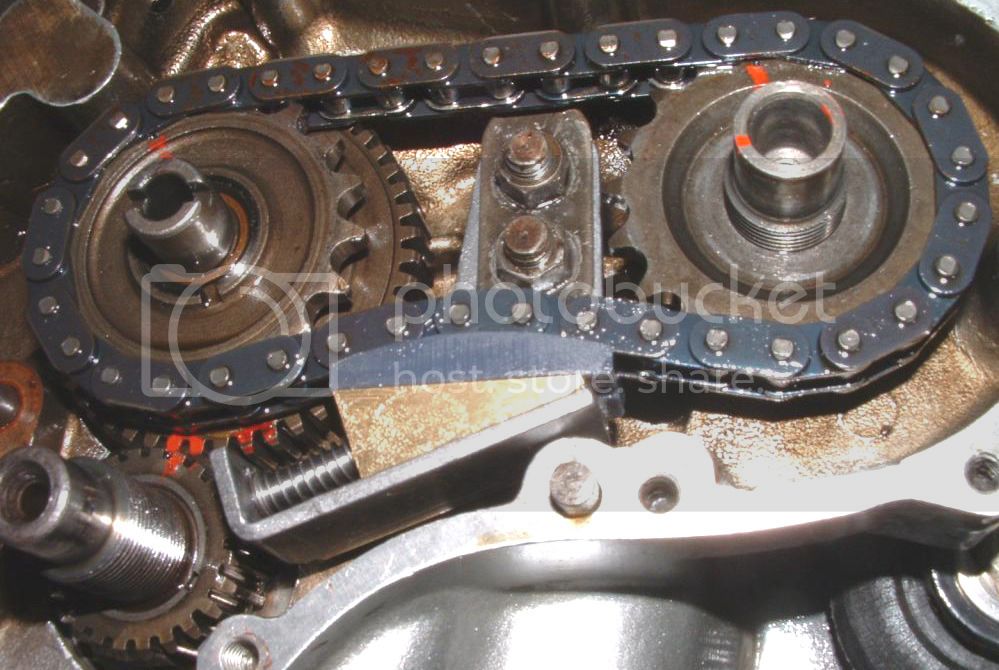

You can advance or retard the cam 5 degrees either way by re-meshing the timing gears and sprockets. To advance the cam, rotate the camshaft sprocket one tooth clockwise within the chain so that there are 11 chain pins between the dots on the sprockets instead of 10 (see photo below). Your cam is now retarded 40 degrees. Then rotate the intermediate gear 3 teeth counter clockwise in relationship to the pinion gear to advance the cam 45 degrees for a net advance of 5 degrees (see new pair of marks on the gear in photo below). Now you can reduce your 5 degrees of advancement to 2 or 3 degrees by filing a tiny .020” step on the camshaft key to turn the cam sprocket slightly counterclockwise in relation to the cam. Before tightening the cam nut, you can slide a tiny sliver of .015” shim stock on the un-filed side of the key to hold things in place if you think it is necessary (it doesn’t have to fit well – just as long as there is a bit of shim in there). If your cam already comes too advanced by a couple degrees when using the original timing marks & locations then you only have to do the last step with the stepped key (retarding). Note that advancing the cam 5 degrees will increase the intake approx .020” and reduce the exhaust lift approx .020” at TDC.

******************************************************************************************************************************

Today I just received a proprietary JS2 cam for Mike (Brooking 850). This cam has some specially designed ramps that will allow it to rev to 9000RPM without valve bounce problems (using Beehive springs, BSA lifters and High strength JS aircraft alloy pushrods). Its taken a lot of time and expense to create this cam and I want to thank Mike for being so patient. Today I will check the cam timing in a mock up motor to make sure the keyway is where it should be. If not then it will need to be adjusted and more money will be thrown at the cam grinder in the hopes that they will be motivated to get the keyway accurately located. In any case - every race motor should have the cam timing checked and adjusted in my opinion.

Johnm - 51 ponies is impressive for a domni 500.

*************************************************************************************************************************************

Time the intake Lobe center at TDC to 102 degrees for JS stage 0 and stage 1 cams. 103 degrees for JS stage 2 & 3 cams (see cam timing instructions and compare the intake to exhaust valve lift at TDC – this is an easier way than finding lobe centers and it comes out the same). At the beginning of the intake stroke, the relationship of the intake lobe center location compared to the exhaust at TDC is what is important – the intake lobe center should be a degree or two less than the exhaust at TDC – this means the cam is advanced a couple degrees because the intake lobe center is closer to 0 degrees at TDC than the exhaust.

You can advance or retard the cam 5 degrees either way by re-meshing the timing gears and sprockets. To advance the cam, rotate the camshaft sprocket one tooth clockwise within the chain so that there are 11 chain pins between the dots on the sprockets instead of 10 (see photo below). Your cam is now retarded 40 degrees. Then rotate the intermediate gear 3 teeth counter clockwise in relationship to the pinion gear to advance the cam 45 degrees for a net advance of 5 degrees (see new pair of marks on the gear in photo below). Now you can reduce your 5 degrees of advancement to 2 or 3 degrees by filing a tiny .020” step on the camshaft key to turn the cam sprocket slightly counterclockwise in relation to the cam. Before tightening the cam nut, you can slide a tiny sliver of .015” shim stock on the un-filed side of the key to hold things in place if you think it is necessary (it doesn’t have to fit well – just as long as there is a bit of shim in there). If your cam already comes too advanced by a couple degrees when using the original timing marks & locations then you only have to do the last step with the stepped key (retarding). Note that advancing the cam 5 degrees will increase the intake approx .020” and reduce the exhaust lift approx .020” at TDC.

******************************************************************************************************************************

Today I just received a proprietary JS2 cam for Mike (Brooking 850). This cam has some specially designed ramps that will allow it to rev to 9000RPM without valve bounce problems (using Beehive springs, BSA lifters and High strength JS aircraft alloy pushrods). Its taken a lot of time and expense to create this cam and I want to thank Mike for being so patient. Today I will check the cam timing in a mock up motor to make sure the keyway is where it should be. If not then it will need to be adjusted and more money will be thrown at the cam grinder in the hopes that they will be motivated to get the keyway accurately located. In any case - every race motor should have the cam timing checked and adjusted in my opinion.

Johnm - 51 ponies is impressive for a domni 500.

- Joined

- Jan 10, 2005

- Messages

- 1,043

Of course if its usable. I found that 5 degrees put the std and PW3 cams closest to their designed opening points at 0,013" tappet lift. I later retarded the PW3 using std marks (it felt very harsh at designed TDC lift and never worked well in my 750 with oversize PO intake ports).Keith - I hope you don't mind me using your photo in my instructions.

- Joined

- Nov 26, 2009

- Messages

- 3,086

jseng1 said:jug said:Jim, forgive me for asking but does filing the key create a risk of creating a stress riser in the keyway resulting in it shearing. Just wondering.

JUG

Not to worry - stepped keys (offset keys) are commonly used on car cams. They just aren't available for Nortons. As far as I know you can't even get the same key with a thicker cross section so you could mill it and make it offset.

- Joined

- Oct 31, 2009

- Messages

- 5,193

Trick question?acotrel said:How many stepped keys would you have to make before you got one which gives 5 degrees advance plus or minus one degree ?

The Commando cam are naturally adjustable in 5 degree increments. The step key is for fine adjustments and I believe is good for 2 degrees one way or the other. This offers many scenarios that I am too lazy to wrap my head around right now.

For example, advance the cam 10 degrees with the key in one way for a total of 12 degrees or the key the other way for a total of 8 degrees.

Simpler idea is to put a step key in with the timing gear in their stock position for a 2 degree advance or retard depending on it orientation of the key on the cam shaft.

lcrken

VIP MEMBER

- Joined

- Mar 15, 2009

- Messages

- 4,982

acotrel said:How many stepped keys would you have to make before you got one which gives 5 degrees advance plus or minus one degree ?

Actually, it's not that hard to get them accurate to within a degree. You can calculate the offset required, based on the diameter of the cam shaft at the keyway. Then if you're filing them down from a wider key, using a vice and hand file, all you have to do is measure with a micrometer or vernier caliper, and file till you get the right offset. I used to do it that way, and it was pretty straightforward. It would be even easier to make them in the mill, and that's how I'd do it now if I needed to make new ones. As Pete pointed out, you only need them in small offsets, like one or two degrees, to get any cam within one degree of where you want it.

Even easier is to use Vernier cam gears, and I've done that in the past with the ones from Fair Spares (now Norvil), but the ones I bought were not very concentric, and had a lot of sprocket runout. Only one out of the three I bought was usable (at least by my standards at the time).

I also tried broaching alternate keyways in stock sprockets, after annealing them, but never found a good way to do them accurately. I did a couple sprockets that way, but to sort out which keyways gave which timing, I had to fit the cam with that keyway into an engine, and measure the timing with a degree wheel and dial indicator. With five keyways, that was five assembly and measurement efforts for each sprocket. And then I had to keep careful notes of which keyways were for which timing settings on each sprocket. I'm sure I could have come up with better jigs to do it accurately, but it was just more trouble than it was worth, so I didn't pursue it any further.

Ken

- Status

- Not open for further replies.