Schwany

VIP MEMBER

- Joined

- Apr 22, 2020

- Messages

- 2,635

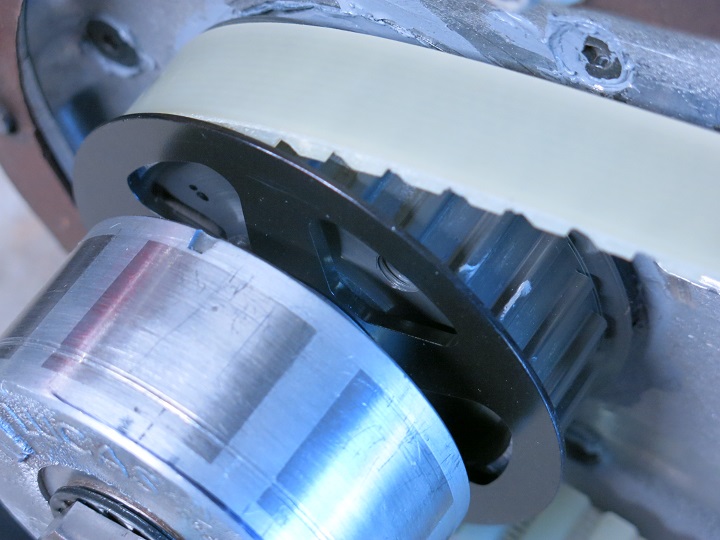

It's done. The cut turned out to have a very flat not rocking surface.

I may cave in and end up putting some small button head screws on the keeper plate. The shoulder width grew a little after cutting the pulley down. Probably not necessary, but it might look cool. ha

Tolerances? It's an old Norton, not an F1 car. lol

RGM has never responded to any of the 4 emails I've sent regarding this clutch kit. Doesn't matter enough to me to call and explain anything.

I may cave in and end up putting some small button head screws on the keeper plate. The shoulder width grew a little after cutting the pulley down. Probably not necessary, but it might look cool. ha

Tolerances? It's an old Norton, not an F1 car. lol

I maybe a bit negative, but that kind of thing doesn't happen anymore in my experience with any of the vendors I've dealt with in the last 4 years.I don't understand why RGM doesn't send you the correct part at their cost.

Glen

RGM has never responded to any of the 4 emails I've sent regarding this clutch kit. Doesn't matter enough to me to call and explain anything.