Schwany

VIP MEMBER

- Joined

- Apr 22, 2020

- Messages

- 2,635

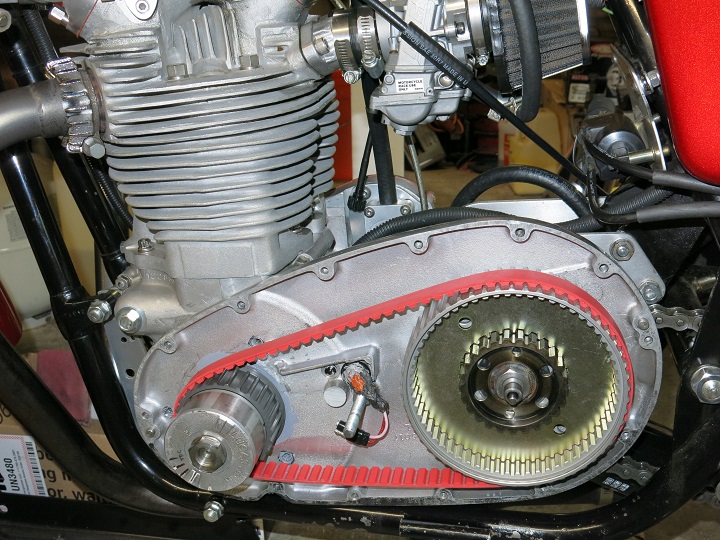

Should be getting a pre-Commando belt drive kit from RGM dropped off on my porch soon. I'm going to see if I can get everything aligned and squeeze it in the P11 primary. The skinny 20mm belt the kit comes with might be pushing it for the grunt my motor makes, but gotta give it a shot. I suspect the kit belt will be too long as well. I know belt drives have been installed in a P11, but I can't find a post that specifically mentions the RGM pre-Commando kit and 20mm belt.

Is the Continental AT10 Gen III Synchroflex 8mm belt RGM uses regardless of width not up to the job? They are timing belts, not drive belts. I believe I read some "don't use that belt" complaining, but I'm not sure if the complainer ever used one on a 750 Norton.

Bring on the gloom and doom advice.

Is the Continental AT10 Gen III Synchroflex 8mm belt RGM uses regardless of width not up to the job? They are timing belts, not drive belts. I believe I read some "don't use that belt" complaining, but I'm not sure if the complainer ever used one on a 750 Norton.

Bring on the gloom and doom advice.