- Joined

- Mar 7, 2020

- Messages

- 3,157

Borrow Ashley's hammer

Have not tensioned the rear chain. Once I get the belt to stay put, I'll look into it.Have you reset the drive chain tension yet? When not using a double adjuster, the drive chain can work for or against you. I had a similar issue with the belt wanting to ride against the outer keeper on my Atlas. I was able to get the belt in a happier spot by fiddling with the rear wheel adjusters/drive chain tension. Ideal? Probably not, my gearbox has some miles on it.

Do you have the paint knocked off the garage wall from hitting it with your head ? Ain't it fun! Without a challenge there would be less satisfaction!

Would be nice if it worked out. The belt running against the inside fence bugs me though. Only thing I did not check too well was the horizontal alignment. Motor or gearbox could be sagging down or pointing up a mm if measured a few feet out. In tight close to the motor the straight edge and a pair of carpenter squares show good against the pulleys. Maybe I'm not channeling my inner anal nutjob well enough. It's a Puzzler.Hope the efforts prove to be worthwhile. For a holigan bike, it needs a strong primary and clutch, IMO. I always found the stock P11 clutch to be too weak for the application, and prone to slippage.

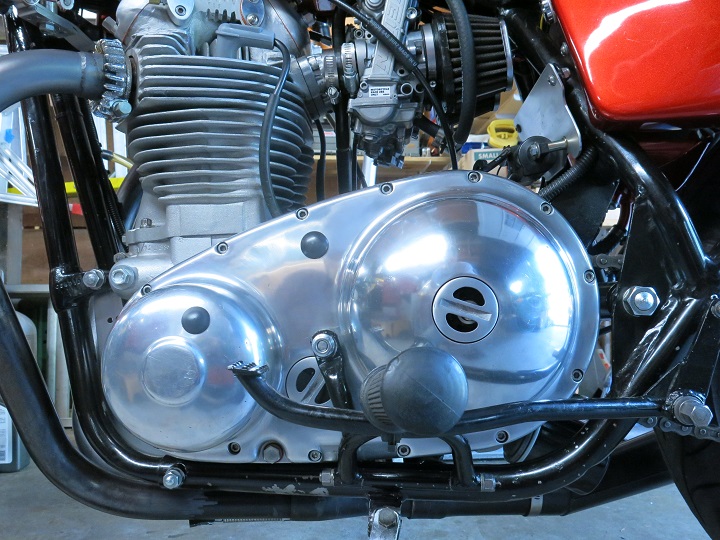

Did you change your gearbox clutch pushrod actuator for a commando one? They have a different ramp I believe?Took the P11 around the block. The RGM clutch is a nice clutch. No banging into 1st cold... yet. Very smooth operating and running clutch, but it did not get hot or stressed during the ride. Outer case only got up to 80 F. That said, yeah the belt got tighter in a very short amount of time. It was skipping a tooth on the first cold kick, but stopped doing that after a short period idling and after the ride.

Was a short ride. I never got out of 1st. My bike is geared high and getting into 2nd gear in a 20 mph zone would have been lugging the motor excessively. Not good for my engine. Tomorrow I'll try going a little further and maybe get into 2nd gear, 3rd gear if I'm lucky. lol

I can't believe anyone ever complained about clutch lever pull on a Commando if this clutch is typical. Lever action feels nice to me. Way better than the stock AMC clutch, or the NEB clutch. Clutch stack is probably high relative to the pressure plate to get the easy lever pull. Might not be ideal for a race bike, but it is nice on the street.

Was it worth it? I don't know. Now I'm thinking about trying to fit a TTi box in there for the win. Seriously though, it's an improvement and I like it. No drips on the garage floor, and a clutch that works like it should. Time to order the pricey Synchroflex 20AT10 880 belt.

Even though my bike is a hooligan special, I'm not going to be doing wheelies and such. It feels like a nice handling cruiser with some beans if I need to use them.

I'll be back if I put a TTi box in the P11. I know it won't be a walk in the park for a parts changer like myself. Maybe somebody will get something out of me doing it. Then again probably not.

Stay frosty

Did you change your gearbox clutch pushrod actuator for a commando one? They have a different ramp I believe?

I could lift the front wheel with my AMC clutch before I put synthetic 0-20 oil in it. That messed it up and all it would do after that is slip if given the slightest amount of throttle. I have a new set of plates for it just in case I might need to use it in the future.The RGM clutch looks like a standard Commando diaphram clutch?

Diapharm clutches always seem to have more holding power and are easier to set up. My stock AMC P11 clutch is not strong enough to lift the heavy front wheel, and often crashes when going into first.

Not a word. I sent 4 emails. Not much point in sending more. He was pleasant and responsive pre purchase, but zero after the parts arrived.Did RGM ever get back to you?

Does anyone know whether Roger is now RGM's only employee? I've placed a couple of orders with him lately with slow turnaround and no answer to email questions concerning other parts I may need.The fine mesh stainless steel screens make the vents look less shade tree engineered, but I assure you they are shade tree engineered. Brass screens might have been more bespoke, but these have some character.

Not a word. I sent 4 emails. Not much point in sending more. He was pleasant and responsive pre purchase, but zero after the parts arrived.

You lays down your money and you takes your chances. I have been as pleasant as possible but it's hard to say thanks for sending me the wrong belt with the kit and the product shows some damage from shipping in a way that it makes the vendor feel good. Damage on the pulley teeth had to be filed smooth. If I lived over there, I would have taken it back and got pulleys with unblemished teeth. They will function like they are, but some of the anodizing is gone.

I asked nicely if RGM could source and supply me with an 880 length belt, but I'd already been written off, and didn't hear squat. I looked about as much as I could deal with on google for a reasonably priced Continental 20AT10 880 Synchroflex Gen3 belt, but ended up buying one from Bolton Engineering Products at what must be retail. If doing this on a N15 or P11, the 880 is a good length to work with using this kit. 890 is too long in my opinion, but might be usable with a 5/16" full perimeter spacer. The PolyTech belt (that was made in France) I sourced here in the US will be in my tool bag as a spare. I probably won't see the new Red belt from Bolton for a while. It's coming royal mail which takes forever due to whatever the trending world crisis of the day is.