Jdub

VIP MEMBER

- Joined

- Dec 1, 2018

- Messages

- 356

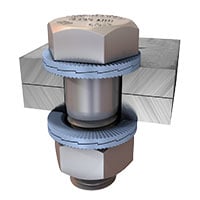

With the clutch basket locking tool I can rest the end against the 1/2 " nut with rubber protection. Will this handle the task?

I could instead install the footrest and swap the footrest to the inside for the same purpose IF I can get the tool arm far enough out to purchase firmly on the footrest spindle.

I could instead install the footrest and swap the footrest to the inside for the same purpose IF I can get the tool arm far enough out to purchase firmly on the footrest spindle.

Last edited: