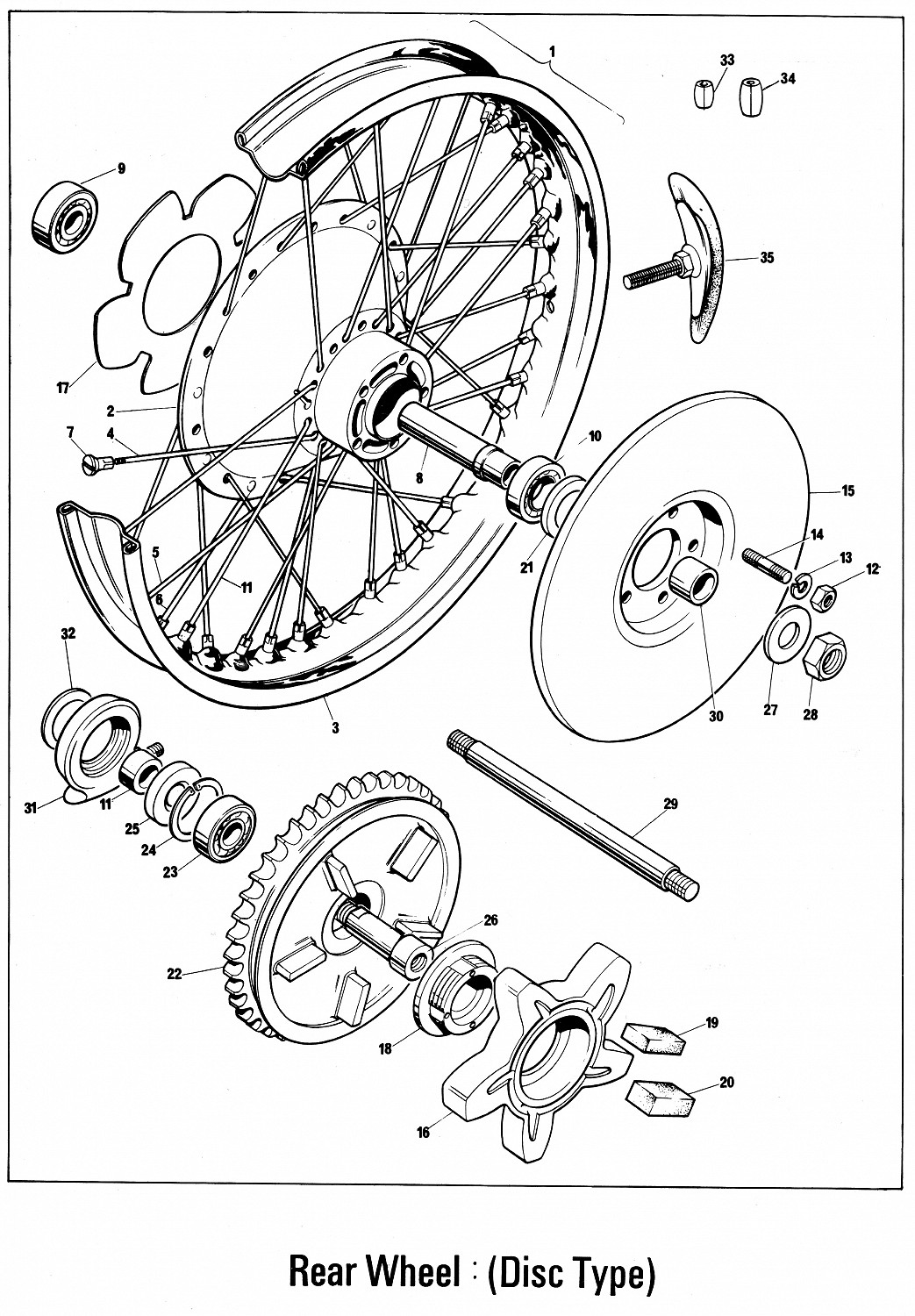

"It's been several years since I converted my MK III to solid rear axle (BEFORE the original broke), and I merely made up spacers (two, I think) and filed the swingarm forks wider to accept the Honda 17MM axle. As I recall, the wheel bearings required no mods or replacements. <...> I've found that by sliding the axle out to the left side, the sprocket can be left in place while removing the wheel." (Frank Forster, 2012)

The simplest solution often IS the best solution. How often do you have to remove the rear wheel? The absence of a dummy axle just means you have to be a little careful when pulling the long solid axle. A mark on the axle will tell you how far out you can safely pull it. Who cares if the lone sprocket is a little wobbly on the protruding shaft end? You can always push the axle back in if you are worried about the sprocket and chain dropping to the ground. See entries #1, #20, #26-27 of this thread.

The solution looks very attractive to me!

Now I wonder which Honda model has (or had) a 17mm axle of suitable length?

= Knut

The simplest solution often IS the best solution. How often do you have to remove the rear wheel? The absence of a dummy axle just means you have to be a little careful when pulling the long solid axle. A mark on the axle will tell you how far out you can safely pull it. Who cares if the lone sprocket is a little wobbly on the protruding shaft end? You can always push the axle back in if you are worried about the sprocket and chain dropping to the ground. See entries #1, #20, #26-27 of this thread.

The solution looks very attractive to me!

Now I wonder which Honda model has (or had) a 17mm axle of suitable length?

= Knut

Last edited: